Humanoids at the Threshold: Building the Standards for a New Robotic Era

Why the future of humanoid robots depends on safety, trust, and the standards we set today

“The future depends on what you do today.” — Mahatma Gandhi

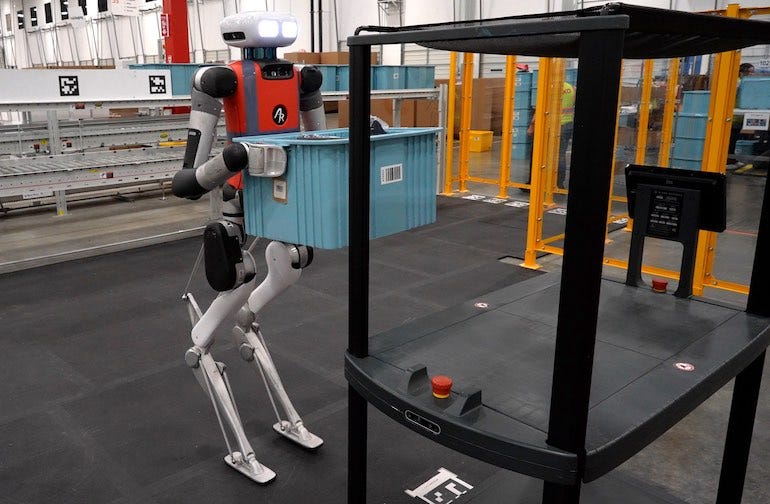

Last year, a humanoid robot named Digit took on a novel assignment: moving boxes of Spanx in a warehouse. It was a small but symbolic step—evidence that humanoids were starting to leave research labs and enter real industrial environments. Digit could lift boxes up to 16 kilograms, ferrying them between trolleys and conveyors. But at a March trade show, the robot suddenly pitched forward and collapsed face-first onto the concrete floor, dropping the container it was carrying.

The fall was more than a clumsy accident. It was a vivid reminder of what’s at stake as humanoids begin sharing space with people. A 1.8-meter-tall, 65-kilogram robot toppling onto a worker isn’t just an inconvenience—it’s a serious safety risk. As Pras Velagapudi, CTO of Agility Robotics, told one reporter: “Your throat is a good example. If a robot were to hit it, even with a fraction of the force it needs to carry a 50-pound tote, it could seriously injure a person.”

That tension—between the promise of humanoids and the risks of their design—has been the backdrop for my work over the past year leading the IEEE Humanoid Study Group. Our final report, A Pathway Study for Future Humanoid Standards, was published earlier this year. It is, in essence, a roadmap for how to make humanoids safe, trustworthy, and ready for widespread deployment.

Why Humanoids Defy Existing Standards

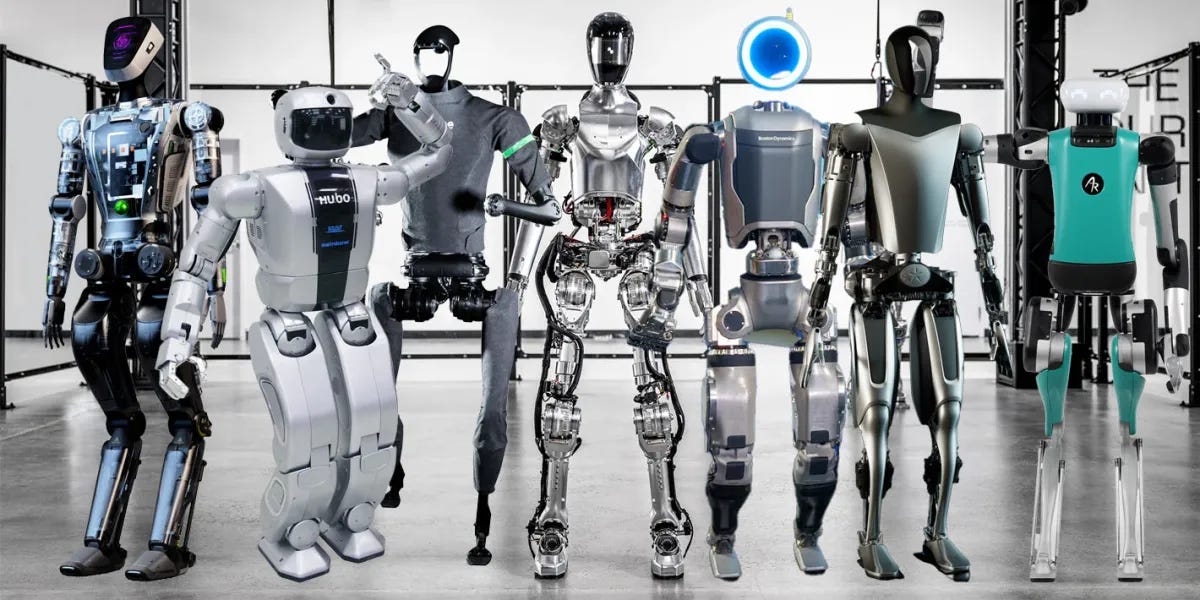

The robotics industry already has standards for industrial arms, mobile platforms, and collaborative robots. But humanoids are different.

Unlike traditional robots, humanoids are dynamically stable. They rely on constant active control to remain upright. Cut the power to an industrial arm, and it freezes. Cut the power to a humanoid, and it falls. That inversion of risk changes the entire safety equation.

Humanoids also operate in human-designed spaces—doorways, staircases, hallways, and shelves—making them attractive as general-purpose machines but also exposing them to unpredictable environments. A humanoid in a factory can’t be cordoned off forever. Its value lies in working alongside people, which means safety is no longer just about guarding humans from machines—it’s about creating trust in daily interactions.

And then there are psychosocial risks. We instinctively anthropomorphize humanoids, assuming they understand more than they do. A robot that looks like a coworker but can only repeat scripted phrases may frustrate or mislead. Conversely, a robot that appears too machine-like may cause anxiety if deployed in sensitive environments such as eldercare. Striking that balance is not just a design challenge—it’s a standards challenge.

A Study Group with 70 Voices

When the IEEE convened our Humanoid Study Group, more than 70 experts joined: engineers, academics, regulators, and end users. My role as chair was to bring order to this chorus of perspectives. Some pushed for rigorous technical detail. Others worried about market timelines. Regulators stressed the need for enforceable safeguards.

At times, the debates were heated. The most spirited came over classification. What counts as a humanoid? Must it have two legs, two arms, and a head? Or is it enough that it operates with humanoid-like behaviors? One of our recommendations is that perhaps we should drop the word humanoid altogether, and instead classify robots by capabilities, behaviors, and use cases.

As I said in one interview: “It felt like building a bridge while the ground underneath kept shifting.” But the friction was valuable. By surfacing disagreements, we forged a framework strong enough to adapt as the field evolves.

The Framework: Three Pillars

Our final report organizes the work into three interconnected pillars:

Classification

We propose a taxonomy that goes beyond appearance. Robots should be defined by their physical capabilities, behavioral complexity, and application domains. This avoids misleading labels—like assuming a “human-shaped” robot must be conversational—and helps standards match real functions.Stability

Stability is the number-one safety concern. Humanoids need clear metrics for balance, fall response, and controlled deceleration. Imagine an emergency stop that doesn’t cut power instantly but instead guides the robot into a safe posture—kneeling, setting down loads—before shutting down. Our goal is to standardize the outcome, not the method, leaving room for innovation while ensuring safety.Human-Robot Interaction (HRI)

Standards must address how humanoids communicate intent. Should robots use lights, sounds, gestures, or haptics? How do we make cues clear in noisy warehouses or crowded public spaces? Beyond physical safety, we must also consider emotional safety, including inclusivity for users with disabilities, stress mitigation, and alignment of a robot’s design with its actual capabilities.

Learning from Digit

Digit’s journey is instructive. Agility Robotics has been testing new safety features for the robot, such as deceleration protocols that ease it into a safe state when humans get too close. Instead of toppling when power cuts, the robot could set down its load and lower itself onto hands and knees.

Boston Dynamics, meanwhile, is leading ISO efforts on “industrial robots with actively controlled stability”—a category that could apply as much to quadrupeds like Spot as to bipeds like Atlas. As Federico Vicentini of Boston Dynamics put it: “We want to standardize the goal, not the way to get to the goal.”

This approach—defining outcomes, not designs—is central to our framework. Standards should establish a minimum baseline for safety and trust while allowing manufacturers the freedom to innovate.

The Human Factor

One of the most revealing parts of our study involved surveys of non-engineers. When asked what they expected from humanoid robots, people overwhelmingly wanted everything: facial expressions, micro-expression recognition, natural gestures, and empathetic communication. As one colleague said, “They wanted something that doesn’t exist.”

This mismatch matters. If a humanoid looks like a person, but cannot act like one, expectations rise and trust falls. I often use a comparison:

“No one expects a self-checkout machine to chat with you or bag your groceries, because it looks like a machine. But if it looked like a friendly clerk and only repeated, ‘Please scan your next item,’ people would quickly get frustrated.”

Standards can help manage these expectations by aligning design with reality and requiring transparency about capabilities.

Crossing the Chasm

Humanoids today are where personal computers were in the late 1970s: early adopters are experimenting, but mainstream acceptance remains elusive. Geoffrey Moore’s Crossing the Chasm model is apt. Humanoids are in the early adopter stage; to reach the early majority, they must prove safe, reliable, and trusted in “beachhead” applications—warehouses, logistics, and healthcare.

Standards are the scaffolding that will allow that leap. Without them, humanoids may stumble in the chasm, slowed by accidents, mistrust, or uneven regulation. With them, the path to broader acceptance is clearer.

Looking Ahead

The work of the IEEE Humanoid Study Group is not an endpoint. It is a call to action. Our report is the starting line. From here, the responsibility lies with SDOs to draft living standards that evolve alongside the technology.

This evolution must balance three priorities:

Safety first: Protecting workers, the public, and vulnerable populations.

Trust through transparency: Ensuring robots are presented as they are, not as we wish them to be.

Innovation unchained: Allowing designers freedom to experiment while holding everyone to a minimum bar of responsibility.

I am proud of what our diverse group achieved. We debated, argued, and occasionally disagreed, but we arrived at a roadmap strong enough to guide the next generation of humanoid standards.

When humanoids eventually step out from behind fences and into shared human spaces—factories, hospitals, homes—I want them to do so under guardrails sturdy enough to protect the people around them while unlocking their enormous potential.

Standards may not be glamorous, but they are the hidden infrastructure of trust. And trust is the bridge humanoids must cross if they are to become not just machines in our midst, but partners in our future.

The full report, A Pathway Study for Future Humanoid Standards, is available for download on ResearchGate.

Robot News Of The Week

Drone startup Guardian Agriculture shuts down

Guardian Agriculture, a Woburn, MA–based agtech robotics startup, has shut down after failing to secure new funding. The company, founded in 2017, was known for its SC1 drone, a 600-lb autonomous quadcopter for aerial crop spraying. The SC1 could carry 200 lb of payload, cover 60 acres per hour, and in 2023 became the first FAA-approved eVTOL system for nationwide commercial use.

Despite industry recognition—including being named one of Time’s Best Inventions of 2024—Guardian struggled to commercialize. By mid-2025, it had built only eight units and had just one paying customer. CEO Ashley Ferguson confirmed the wind-down in August 2025, with Fall Line Capital managing liquidation. The startup had raised $51.7M, including a $20M Series A in 2023.

Guardian’s closure highlights the steep commercialization challenges in agricultural robotics, where high R&D costs, slow farmer adoption, and limited early revenue often outpace funding. Meanwhile, the sector is still attracting investment: 4AG Robotics ($29M for mushroom harvesting), TRIC Robotics ($5.5M for pest control), and Beewise ($50M for AI beekeeping), with John Deere deepening its autonomy play by acquiring GUSS Automation.

MassRobotics announces Physical AI Fellowship powered by AWS Startups, NVIDIA Inception

MassRobotics has launched the Physical AI Fellowship, a virtual program backed by AWS Startups and NVIDIA Inception to accelerate robotics startups developing intelligent machines for real-world applications. The inaugural Fall 2025 cohort features companies such as Bedrock Robotics, Blue Water Autonomy, Diligent Robotics, Generalist AI, RobCo, Tutor Intelligence, Wandercraft, and Zordi.

The fellowship provides startups with direct technical guidance from AWS scientists, access to NVIDIA’s accelerated computing stack, cloud and compute resources, and integration into MassRobotics’ global ecosystem. Fellows also receive AWS credits, training opportunities, and the chance to showcase their work at major events.

MassRobotics Executive Director Tom Ryden said the initiative will help startups validate and scale their technologies at a moment when industries are racing to adopt automation. Leaders from AWS and NVIDIA emphasized that physical AI is the “next frontier,” bringing digital intelligence into machines that operate in the physical world and unlocking new levels of productivity, safety, and efficiency across industries.

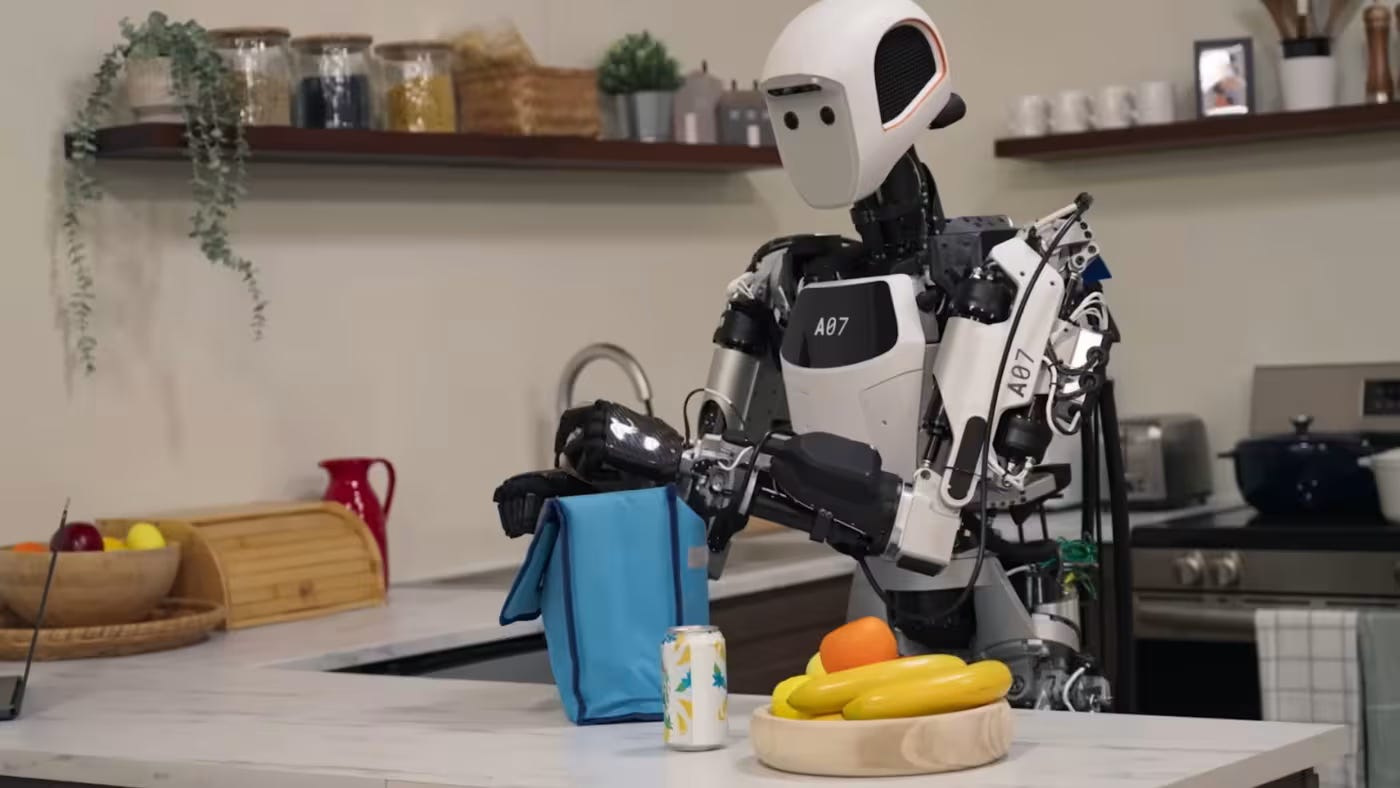

Google DeepMind unveils new robotics AI model that can sort laundry

Google DeepMind has launched new AI models—Gemini Robotics 1.5 and Gemini Robotics-ER 1.5—to advance robot reasoning and problem-solving. Unlike earlier systems that handled one instruction at a time, these models let robots plan and execute multi-step real-world tasks such as sorting laundry, packing bags (while even checking weather forecasts), and recycling correctly using local guidelines.

The models combine vision, language, and action, and can even draw on online tools like Google Search. A key breakthrough is “motion transfer,” allowing skills developed for one robot body (e.g., robotic arms) to be applied to others (e.g., humanoids), helping overcome the shortage of training data in robotics.

Experts say this could bring robotics closer to a “ChatGPT moment,” though others caution the robots are still recognizing patterns rather than truly “thinking.” Major hurdles remain—greater dexterity, safety, and the ability to learn from human demonstrations—before such robots can be widely deployed in daily life and industry.

Robot Research Of The Week

Next-generation humanoid robot can do the moonwalk

KAIST’s Humanoid Robot Research Center has unveiled a next-generation humanoid lower-body platform with world-class mobility, reaching speeds of 12 km/h, climbing 30 cm steps, and maintaining balance even with eyes closed or on rough terrain. Designed at human scale (165 cm, 75 kg), the robot can perform complex motions like the duckwalk and moonwalk, showing potential for industrial use.

What makes this platform stand out is KAIST’s full independence in both hardware and software: the team designed and built all core components—motors, reducers, drivers—and developed an AI controller through reinforcement learning that successfully transferred from simulation to real-world environments.

Collaborating with MIT and other KAIST labs, the team is working toward a complete humanoid with arms, hands, vision, and navigation systems capable of carrying loads, operating valves, pushing carts, and climbing ladders. They also developed a single-leg hopping robot that demonstrated advanced agility, including 360° somersaults, further proving the strength of their AI control approach.

The research will be showcased at Humanoids 2025 and CoRL 2025, marking a milestone in Korea’s push for self-reliance in humanoid robotics technology and advancing robots designed to work alongside humans.

Robot Workforce Story Of The Week

Alfred State receives a $474,000 grant to create robotic pathways

New York’s Alfred State College has received a $474,019 NSF Advanced Technological Education grant to launch “Developing a Robotics and Automation Technician Pathway for the Agricultural and Industrial Sectors.” Led by assistant professors Jessica Hutchison and Dr. Mohamed Eleshaky, the project will prepare students for high-demand robotics and automation jobs, particularly in rural areas critical to food security and manufacturing.

The program will build industry-aligned pathways, offering immersive summer institutes, industry-recognized credentials, and pre-enrollment math courses to reduce barriers. Students will gain hands-on experience with technologies like programmable robotic dogs, boosting interest and confidence in technical fields.

The initiative also emphasizes recruitment, retention, and representation, ensuring a more diverse and prepared workforce. Local businesses stand to benefit from a pipeline of skilled technicians ready to adapt to increasing automation.

College leaders and Rep. Nick Langworthy praised the grant as a workforce investment, strengthening the region’s competitiveness while giving students access to well-paying careers. Alfred State’s applied learning approach and cross-school collaboration will be key to delivering on the grant’s goals and expanding the college’s capacity to meet workforce needs.

Robot Video Of The Week

Robots are taking a beating these days — literally.

A viral video from startup Skild AI shows an engineer taking a chainsaw to a robot dog’s limbs to test its resilience. The company claims its new “robot brain” can adapt to almost any body — even one with shattered parts or missing motors.

The result? Even after losing all four legs, the robodog still managed to hobble forward. It’s both unsettling and impressive, highlighting how far adaptive AI has come in enabling robots to recover from extreme damage.

What do you think — breakthrough innovation or a troubling glimpse of the future?

Upcoming Robot Events

Sept. 27-30 IEEE Conference on Robot Learning (Seoul, KR)

Sept. 30-Oct. 2 IEEE International Conference on Humanoid Robots (Seoul, KR)

Oct. 6-10 Intl. Conference on Advanced Manufacturing (Las Vegas, NV)

Oct. 15-16 RoboBusiness (Santa Clara, CA)

Oct. 19-25 IEEE IROS (Hangzhou, China)

Oct. 27-29 ROSCon (Singapore)

Oct. 29-31 Intl. Symposium on Safety, Security, and Rescue Robotics (Galway, Ireland)

Nov. 3-5 Intl. Robot Safety Conference (Houston, TX)

Dec. 1-4 Intl. Conference on Space Robotics (Sendai, Japan)

Dec. 11-12 Humanoid Summit (Silicon Valley TBA)

Mar. 16-19 Intl. Conference on Human-Robot Interaction (Edinburgh, Scotland)

Mar. 29-Apr. 1 IEEE Haptics Symposium (Reno, NV)