Additive Construction Is Scaling. Our Safety Framework Must Catch Up

The accelerated rise of construction robotics demands standards designed for the jobsite, not the factory

“Safety is something that happens between your ears, not something you hold in your hands.” — Jeff Cooper

At jobsites around the world, something extraordinary is happening. You can see it at dawn in Georgetown, Texas, when a 3D-printing gantry begins its daily ritual of laying down a new row of homes. You can see it in Heidelberg, Germany, where a massive printed “server hotel” is rising like a concrete cathedral. And you can see it in cities planning their first printed affordable-housing communities—places where the cost and pace of construction have long outstripped worker availability.

These machines are no longer curiosities. They are part of the construction landscape. And yet, for all their potential, they are entering environments for which our safety standards were never designed.

This week, ASTM International formally launched the Additive Construction Robot Safety Task Group, the first effort of its kind, and frankly, long overdue. The convergence of robotics and additive construction is accelerating faster than expected. Printers have outgrown the labs that birthed them. They are now operating in human-dense, variable, unpredictable environments. That shift demands a new safety framework—and it requires it now.

From Controlled Cells to Chaotic Jobsites

For decades, industrial robot safety standards like ISO 10218 and ANSI/RIA R15.06 have quietly shaped modern manufacturing. They assume fenced cells, predictable workflows, stable foundations, and trained operators. Even newer collaborative-robot guidance assumes a level of environmental control that is entirely absent from a construction site.

Construction printers exist in a different universe. Their work envelope grows as the structure rises. A walkway that was safe yesterday can be a strike zone today. Weather—rain, heat, lightning, wind—becomes a safety factor, not an inconvenience. Printers draw their “safety perimeter” on ever-changing terrain. And mixed crews, from masons to electricians to laborers, are navigating around high-pressure cement hoses and moving gantries that can span 20 or even 30 meters.

In short: the assumptions built into factory robot standards fall apart the moment a printer rolls onto an open jobsite.

We’ve proven that we can print buildings. Now we have to prove we can print them safely.

Progress on Materials, Not on Machines

Over the last few years, the industry has made real progress in standardizing the output of additive construction. ICC-ES AC509 gave building officials a path to approve printed concrete walls. UL 3401 provided a structured approach to evaluating printed elements. ISO/ASTM 52939—developed by ASTM’s F42 Committee and ISO TC 261—established a qualification and quality-assurance framework for the additive construction process.

These were essential milestones. They gave regulators confidence in the product.

But a printed wall is not the whole story. Those standards tell you how to certify the bricks, not how to run the bricklayer.

ISO/ASTM 52939 stops explicitly at environmental, health, and safety. It is not a robotic safety standard. It does not tell a superintendent how to manage exclusion zones that change every hour. It does not describe how faults in a pumping system should trigger a safe stop in a printer. It does not define weather thresholds or crew-training expectations or the choreography between humans and machines in a dynamic construction environment.

That gap is no longer theoretical. It is showing up daily on jobsites.

Why ASTM Is Stepping In Now

This is why the formation of the ASTM Additive Construction Robot Safety Task Group within Committee F45 matters. It is the first serious, coordinated attempt to build a robotic safety framework tied to real field conditions—not factory theory.

The group is led by Purdue University’s Sogand Hasanzadeh and Ph.D. researcher Jorge Rojas, two of the sharpest minds studying construction robotics safety today. They are already working closely with NIOSH’s Construction Safety team, examining incidents, near-misses, human-robot interaction risks, and environmental variables that do not exist in traditional robotic applications.

The task group brings together an unusually broad coalition: advanced construction robotics companies, labor unions like LiUNA, academic research labs, general contractors, insurers, government researchers, and global safety scientists. Their collective message is clear: if we want additive construction to scale, we cannot rely on borrowed standards from another industry.

This work is not happening in isolation. It will be coordinated with ASTM F42’s additive manufacturing standards, NIST’s multi-year “Path to Standardization” workshops, and the insights of building-code organizations that need a roadmap for approving these systems. The goal is coherence—one framework, not competing interpretations.

What the Industry Needs Next

A proper safety standard for additive construction robotics must address the realities of construction, not the ideal conditions of a robotics lab. It must account for the interplay between motion and material systems, the volatility of outdoor environments, and the presence of human workers who must approach the printer during active operation.

It must define how exclusion zones adjust as a structure grows.

It must require interlocks that tie pump pressure, nozzle motion, and curing behavior into a unified risk-reduction system.

It must outline weather thresholds that are based on data, not manufacturer preference.

It must establish training expectations for mixed crews working alongside large autonomous systems.

And it must give regulators, safety managers, and insurers something they currently lack: a common language.

This is not about slowing innovation. It is the opposite. A shared safety framework accelerates adoption by building confidence—for workers, contractors, building officials, and the public.

The Responsibility in Front of Us

Additive construction has reached the moment where its most significant barrier is not imagination or capability—it is governance. We are rapidly approaching a world where printed structures are normal and printed neighborhoods are common. But we cannot enter that world with a safety playbook designed for another industry.

This is the time to write the missing chapter.

ASTM’s new task group is the first step toward that chapter. It gives us a forum, a structure, and a collective mandate to match technology with responsibility. If we do this right, we can help shape a future where construction robotics is not only efficient and scalable, but safe, predictable, and trusted.

The concrete printers have arrived. The standards must be followed.

Robot News Of The Week

1HMX has unveiled the Nexus NX1, a fully integrated whole-body human-machine interface combining HaptX Gloves, Virtuix Omni One, Freeaim robotic shoes, and 72-DoF motion capture. Designed for humanoid robot teleoperation, embodied AI, and hyper-realistic VR training, Nexus NX1 delivers natural control, lifelike haptics, and unmatched immersive data fidelity.

North American robot orders increase in Q3 2025, reports A3

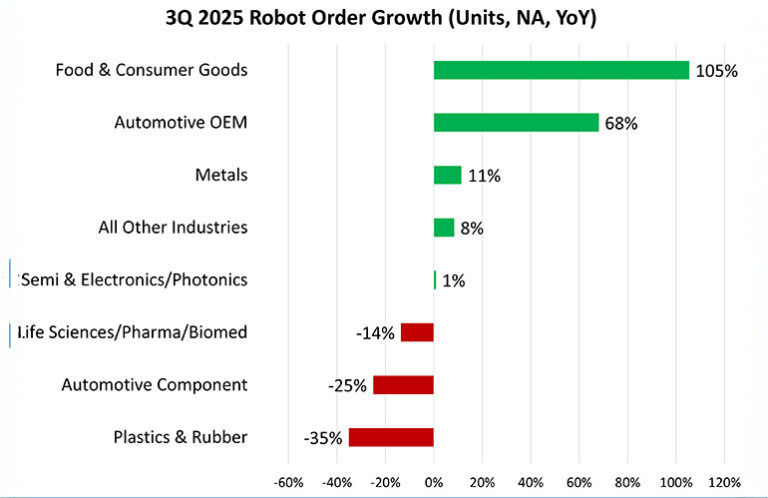

North American robot orders rebounded in Q3 2025, rising 11.6% in units and 17.2% in revenue, according to A3. Growth was driven by food and consumer goods (+105%) and automotive OEMs (+68%), with non-automotive sectors accounting for 59% of all orders. Collaborative robot sales also expanded. Despite economic uncertainty, A3 reports growing confidence as manufacturers turn to automation to boost productivity, address labor shortages, and strengthen supply chains heading into 2026.

Rivian launches Mind Robotics as a spinoff to advance industrial AI

Rivian has launched a new spinoff, Mind Robotics, led by CEO RJ Scaringe and backed by $115 million in seed funding. The company aims to advance industrial AI, using Rivian’s operations data to develop robotics and AI systems that transform how physical-world businesses operate across a wide range of industrial applications.

Robot Research Of The Week

Teaching Robots to Fall Gracefully: How Reinforcement Learning Is Redefining Failure

Disney Research and ETH Zurich have developed the first general RL framework that teaches bipedal robots to fall gracefully. Instead of collapsing uncontrollably, robots learn to minimize impact, protect sensitive components, and land in user-specified poses—enabling safer, expressive, and recovery-friendly falls in both simulation and real-world tests.

Real-world helper exoskeletons come closer to reality with AI training

Georgia Tech researchers have developed an AI tool that can rapidly train exoskeleton controllers using existing human movement data—eliminating the need for costly labs and repeated retraining. This breakthrough makes it far more practical to develop and deploy wearable robots that assist mobility across hip and knee movements, accelerating real-world adoption.

Robot Workforce Story Of The Week

How Mississippi State Is Helping Farmers Master Spray Drones

Mississippi State University is helping farmers adopt spray-drone technology through a new 13-part video series from the Agricultural Autonomy Institute. Covering everything from basics to troubleshooting, the series guides safe, efficient UAS use while supporting research that advances precision agriculture and strengthens Mississippi’s farming economy.

Robot Video Of The Week

Hyundai is showcasing how AI, robotics, and next-generation exo technology are redefining modern manufacturing—connecting cutting-edge factories from Singapore to Georgia to build a smarter, cleaner, and more human-centered future.

Upcoming Robot Events

Dec. 1-4 Intl. Conference on Space Robotics (Sendai, Japan)

Dec. 1-5 SOSV’s VC-Founder Robotics Matchup (Virtual)

Dec. 11-12 Humanoid Summit (Silicon Valley)

Jan. 5-6 UK Robot Manipulation Workshop (Edinburgh, Scotland)

Jan. 6-10 Consumer Electronics Show (Las Vegas, NV)

Jan. 19-21 A3 Business Forum (Orlando, FL)

Jan. 21-23 RoboDEX (Tokyo, Japan)

Feb. 3-5 MD&M West (Anaheim, CA)

Mar. 16-19 Intl. Conference on Human-Robot Interaction (Edinburgh, Scotland)

Mar. 23-27 European Robotics Forum (Stavanger, Norway)

Mar. 29-Apr. 1 IEEE Haptics Symposium (Reno, NV)

Mar. 30-Apr. 2 Global Industrie (Paris, France)

Apr. 20-24 Hannover Messe (Hannover, Germany)

May 27-28 Robotics Summit & Expo (Boston, MA)

June 1-5 IEEE ICRA (Vienna, Austria)

June 22-25 Automate (Chicago, IL)

Sept. 14-19 International Manufacturing Technology Show (Chicago, IL)

Oct. 6-8 Motek (Stuttgart, Germany)

The dynamic exclusion zone issue really hits home. When the work envelpe changes as the structure grows, you cant rely on static safety perimeters anymore. I think the most challenging part will be getting all those stakholders aligned on what acceptable risk looks like on a real jobsite.

It is cool to see additive manufacturing scaling now. I’m a total futurist so I love it. But this is a critical point as well, we need safety standards to be there too. Let’s not write the new standards in blood. We know what we need to do.