Is It Time For The Robotics Industry To Employ Full Time Standards Writers?

A new version of ISO 10218, the core industrial robot standard, was published this month - it is the first major update in 14 years.

Aaron’s Thoughts On The Week

"Perfection is attained not when there is nothing more to add, but when there is nothing more to take away." — Antoine de Saint-Exupéry

As robotics advances at an unprecedented pace, the need for clear, comprehensive, and timely standards has never been greater. These standards ensure safety, performance, and best practices across the industry. Traditionally, robotics standards have been developed by volunteer committees of experts who contribute their time alongside their full-time jobs. While this process brings deep expertise, it can be slow and fragmented.

This past week, the newly revised ISO 10218 was published. The standard was first introduced in 2006 and got its first update 2011, but it took 14 years to get to this third update. Think how much has changed in robotics between 2011 and today. ISO/TS 15066 was published in 2016 to address the new field of safety requirements for collaborative robots. That work got integrated to the update ISO 10218. Robots like AMRs got their own standards, some actually in conflict with each other, because different groups attempted to do their own work on standards for them. Some point to the slow speed of developing standards is causing some groups to fire up their own work to address the issue, but it can and does lead to duplication of efforts. This further wastes the time of the volunteers that need to correct the conflict between the two standards now.

I have been a volunteer standard developer for many years, and it has been a real struggle. Volunteers can only devote so much time to developing a new robot standard. Not only do they need to find the time to volunteer, but they also need their employer to support them in that work. Employers must agree to not only allow them to volunteer their time but also, most of the time, pay for their travel to and from the development meetings. When employers cut back on travel, standards development can slow even more. Then we wonder why it takes 14 years to update a standard.

Let me be clear. The work of our standards development volunteers is nothing short of amazing. They are some of the best in our industry and they have nothing but love for our industry and that is why they do what they do. But delays turn into more delays. Our volunteers have day jobs and other responsibilities, they can’t always give their time. They also may change jobs and if we are lucky they come back with their new employers, but sometimes they just exit the process and we need to find others to pick up the proverbial ball and run with it. This framework may no longer work for a technology that evolves and advances as quickly as robotics does. We need to add a new role to the process, just so we can keep up.

An alternative approach is emerging for robotics standards: hiring professional standards writers—dedicated individuals responsible for drafting the actual text of standards while still allowing volunteer experts to review and approve the final versions. This model, already used in some industries and starting to grow slowly with some standards groups working on robotics, could dramatically accelerate robotics standardization. However, it comes with both advantages and challenges.

Pros of Professional Standards Writers

Speed and Efficiency—Volunteer-driven standards committees often experience long delays due to scheduling conflicts and time constraints. Professional writers can streamline this process, ensuring drafts are developed and revised much faster while volunteers focus on content and approval.

Consistency and Clarity—Technical experts excel in knowledge but may not always be the best at writing clear, structured standards. Professional writers bring expertise in technical writing and ensure the standards are well-organized, consistent, and easily interpretable by engineers, policymakers, and manufacturers.

More Time for Experts to Focus on Content - Rather than spending countless hours debating wording, volunteer experts can focus on technical accuracy, real-world applicability, and compliance issues. This division of labor allows for higher-quality standards without overburdening already-stretched professionals.

Keeps Pace with Rapid Robotics Innovation - The robotics industry is evolving faster than ever, but traditional standards development can lag behind new technologies. Professional writers ensure that standards evolve quickly, helping businesses comply with the latest safety and performance benchmarks.

Cons of Professional Standards Writers

Cost Considerations - Paying professional writers introduces a financial burden, requiring organizations to secure funding. Volunteer committees, while slower, don’t have “direct” labor costs—making them a more budget-friendly approach (also makes it easier to cut).

Risk of Disconnect from Industry Realities - While professional writers excel at structuring and drafting, they may lack deep, hands-on robotics expertise. If not closely integrated with volunteer experts, the standards could be technically incomplete or impractical.

Potential for Bias Toward Speed Over Thoroughness - Fast-tracking the writing process may pressure volunteer committees to approve drafts too quickly, potentially overlooking critical nuances that a slower, more iterative process would catch. Rushing to publish could compromise quality.

Challenges in Gaining Consensus—Even with professional writers, standards must still undergo rigorous approval processes. If volunteers feel disconnected from the writing process, they may push back more forcefully during reviews, potentially delaying final approvals rather than speeding them up.

Finding the Right Balance

A hybrid approach—combining the efficiency of professional standards writers with the technical depth of volunteer experts—may offer the best of both worlds.

How a Hybrid Model Works

Professional writers handle drafting and structuring, ensuring speed, clarity, and consistency in documentation.

Volunteer experts guide technical content, approve drafts, and provide real-world insights based on industry needs and best practices.

Collaboration between both groups ensures that standards are not only accurate and technically sound but also well-organized, readable, and implemented faster.

Integrating professional writers without sidelining technical experts allows robotics standards to be developed faster, clearer, and with greater real-world impact.

Examples of Hybrid Standardization Models

Other industries have successfully integrated professional standards writers with expert oversight:

Aerospace & Aviation (SAE, FAA, ICAO) – Professional writers draft structured regulations while industry experts review for technical feasibility and compliance.

Medical Devices (FDA, ISO 13485) – Regulatory documentation is written by professionals but heavily guided by biomedical engineers and clinicians.

Cybersecurity & AI Ethics (NIST, IEEE 7000 Series) – Experts define ethical guidelines, while technical writers ensure that policies are clear and implementable.

These industries show that speed and accuracy are not mutually exclusive—they can coexist with the right division of labor and oversight process.

The Future of Robotics Standardization

The robotics industry is at an inflection point, and standardization must keep pace with advancements in AI, humanoid robots, and automation. If done correctly, a hybrid model could revolutionize the creation of robotics standards, making them more efficient, practical, and widely adopted.

The next question is who funds these professional writers. Some standards development organizations will be able to fund some of these professionals, but for the robotics industry, that may not be enough. Something similar to China’s use of professional standards writers may be needed.

China's commitment to integrating professional standards writers is evidenced by its inclusion of robotics in the national 14th Five-Year Plan. This plan outlines tasks such as strengthening core technology research, developing cutting-edge technologies, and establishing national robot standardization organizations to accelerate the formulation and application of essential standards.

Would a professionally written but expert-reviewed model be the best way forward? The robotics industry may soon find out.

Robot News Of The Week

VDMA urges EU policymakers to boost its robotics competitiveness

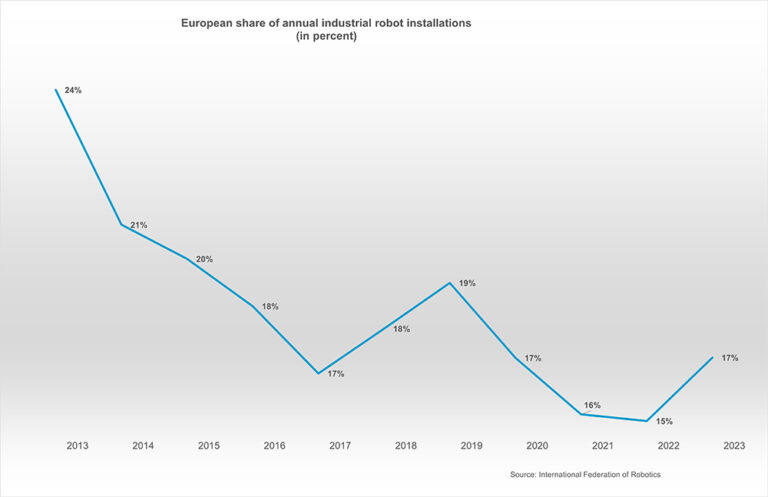

VDMA Robotics + Automation issued a call to action urging EU policymakers to boost robotics and automation to regain global competitiveness. Their Robotics Action Plan for Europe highlights how China’s rapid automation growth has outpaced the EU, where robot density remains lower.

The VDMA’s four key recommendations include:

A robotics boost to enhance competitiveness and sovereignty.

Increased venture capital to support European startups.

A competition roadmap to benchmark progress against Asia and North America.

Focus on economies of scale to bring innovations to market successfully.

With Europe's share of global robot installations dropping from 24% to 17% in a decade, the VDMA warns that urgent action is needed. Dr. Dietmar Ley emphasized that robotics and automation are essential for productivity, innovation, and economic resilience. "We have no time to lose."

Lab0: Robotics system first to fully automate inbound warehouse ops

Lab0, an industrial automation company in Ridgefield, WA, unveiled RoboGlide, the first humanoid-inspired system for fully automating inbound warehouse operations. Developed in secrecy for two years, RoboGlide integrates multiple logistics stages, including unloading, sorting, and palletizing, cutting unloading costs by 75% or more.

The system features dual-arm picking, AI-powered vision (Percept0), and Nvidia’s Isaac Lab technology, enabling high-speed, autonomous logistics. Unlike off-the-shelf solutions, Lab0 built its own AI-driven systems for superior accuracy and reliability.

Already deployed at a top 10 global small-box retailer, RoboGlide sets a new standard for warehouse automation.

Founded by David McCalib, an MIT alumnus and former Kiva Robotics leader, and CEO Steve Toebes, Lab0 focuses on scalable, modular solutions to eliminate inefficiencies. Toebes calls RoboGlide the first of many innovations aimed at automating entire facilities.

Figure’s humanoid robot takes voice orders to help around the house

Figure has unveiled Helix, a Vision-Language-Action (VLA) model designed to enhance humanoid robots’ ability to understand and perform tasks using visual and language prompts. This comes two weeks after CEO Brett Adcock announced the company’s shift away from OpenAI collaboration.

Similar to Google DeepMind’s RT-2, Helix allows robots to process commands, assess environments, and execute actions in real time. It enables object generalization, allowing robots to pick up new household items without prior training. Helix can also coordinate multiple robots to complete tasks collaboratively.

While industrial applications remain Figure’s primary focus, the Helix announcement signals growing interest in household robotics, an area hindered by complex environments, high costs, and labor-intensive training. Figure sees Helix as a step toward scalable, adaptable home automation.

Despite being in early stages, Helix is a bold push toward making humanoid robots more intuitive and versatile.

Robot Research In The News

Artimus Robotics wins UK ARIA Award to Accelerate the Development of Dexterous Robotic Hardware

Artimus Robotics has secured £1.5M in funding from the UK’s Advanced Research + Invention Agency (ARIA) to advance its artificial muscle technology. The project, part of ARIA’s £57M Robot Dexterity programme, focuses on enhancing soft actuation and integrating it into robotic manipulators in collaboration with the University of Bristol.

Led by Dr. Nicholas Kellaris, Artimus aims to improve actuator performance, materials, and fabrication while working with Dr. Efi Psomopoulou to develop high-strength, fast, and adaptable robotic manipulators.

Artimus CEO Dr. Eric Acome emphasizes the importance of hardware innovation in robotics, while ARIA’s Jenny Read highlights the efficiency and dexterity potential of HASEL technology. If successful, this project could revolutionize robotic manipulation with cost-effective, lifelike motion.

WPI Researchers to Develop Robotic Arm for Wheelchairs

Worcester Polytechnic Institute (WPI) researchers are developing an origami-inspired soft robotic arm to help wheelchair users grasp, lift, and carry objects. Funded by a $1.3M NSF grant, the four-year project, led by Cagdas Onal, Berk Calli, and Loris Fichera, focuses on lightweight, flexible robotic arms that offer greater reach and safety than traditional rigid systems.

The team is designing spring-like, plastic-based modules that enhance strength, stiffness, and precision while remaining compact. Specialized algorithms and AI will control the arm’s movements, ensuring stability and accuracy.

Unlike rigid robots, soft robots can expand and shrink, making them ideal for assistive applications. The goal is to create a robotic arm that can handle delicate objects, like a cup of water, without spilling.

This breakthrough could significantly enhance independence for wheelchair users, marking a major step toward safer, more adaptable assistive robotics.

Robot Workforce Story Of The Week

Lynda Adkins sits at the helm of the Oak Park Elementary School's effort to introduce kids to robotics curriculum.

Robot Video Of The Week

Clone Robotics unveiled the Protoclone V1, a full-bodied synthetic human with 200+ degrees of freedom, 1,000 Myofibers, and 500 sensors. The faceless android, showcased in a viral video, blends human-like anatomy with advanced robotics. Set to transition from pneumatics to hydraulics, it aims for real-world applications beyond research. Very interesting and very creepy.

Upcoming Robot Events

Feb. 24-26 Intl. Conference on Mechatronics and Robotics Engineering (Lille, FR)

Mar. 4-6 Intl. Conference on Human-Robot Interaction (Melbourne)

Mar. 17-21 NVIDIA GTC AI Conference (San Josa, CA)

Mar. 21-23 Intl. Conference on Robotics and Intelligent Technology (Macau)

Mar. 25-27 European Robotics Forum (Stuttgart)

Apr. 23-26 RoboSoft (Lausanne, Switzerland)

Apr. 30-May 1 Robotics Summit (Boston, MA)

May 12-15 Automate (Detroit, MI)

May 17-23 ICRA 2025 (Atlanta, GA)

May 18-21 Intl. Electric Machines and Drives Conference (Houston, TX)

May 20-21 Robotics & Automation Conference (Tel Aviv)

May 29-30 Humanoid Summit - London

June 30-July 2 International Conference on Ubiquitous Robots (College Station, TX)

Aug. 18-22 Intl. Conference on Automation Science & Engineering (Anaheim, CA)

Oct. 6-10 Intl. Conference on Advanced Manufacturing (Las Vegas, NV)

Oct. 15-16 RoboBusiness (Santa Clara, CA)

Oct. 19-25 IEEE IROS (Hangzhou, China)

Nov. 3-5 Intl. Robot Safety Conference (Houston, TX)

Dec. 11-12 Humanoid Summit (Silicon Valley TBA)

Interesting read! OpenAI's approach to reducing hallucinations through RAG is definitely a step in the right direction. Adding retrieval-augmented generation makes sense for factual data but I wonder how OpenAI ensures the model doesn't overly rely on external sources, limiting its creative abilities. Any insights on that?

I wonder if a Focused Research Organisation could be a way of enabling professional standards writers? Convergent Research has a call for proposals closing on March 28th: https://www.convergentresearch.org/frost-uk