Kicks, Falls, and Finish Lines: The Surprising Role of Sports in Robotics Testing

From soccer pitches to sparring rings, robots are earning their stripes in the world’s toughest testing grounds.

“Everyone has a plan until they get punched in the mouth.” – Mike Tyson

What do a soccer pitch, a marathon route, and a martial arts dojo have in common? For humanoid robots, these aren’t just arenas for competition—they’re high-stakes testing grounds. In recent years, we’ve seen robots pass soccer balls, run marathons, and even spar in controlled combat. While these events often grab headlines for their novelty, they serve a deeper purpose: they stress-test robotics technology in ways traditional labs simply can’t replicate.

At their core, these competitions offer something robotics has long craved—unstructured, unpredictable, and physically demanding environments. They’re helping researchers uncover design flaws, validate control systems, and build a foundation for performance expectations that mirror the structure of formal test standards. In short, robot sports are becoming the playgrounds where the next generation of standards will be born.

Why Sports? Because Real Life Doesn’t Pause

Labs are useful, but they’re controlled. Sports aren’t. When a robot joins a soccer match or runs a half-marathon, it’s stepping into a world where nothing is guaranteed. It might have to recalibrate its vision system in bright sunlight, adjust gait on uneven pavement, or avoid another robot barreling toward it with a ball. These real-world challenges are precisely what make robot sports so helpful in evaluating performance under stress.

This is also where they begin to resemble the building blocks of test and performance standards. Just as standards like ISO 13482 define safety and functional requirements for service robots, sporting competitions create de facto assessments of autonomy, resilience, perception, and control. But unlike lab-based tests, they do so holistically and in real time. A robot in a race isn’t just executing a pre-programmed routine, it’s reacting, adapting, and recovering. That’s not just performance, it’s real-world readiness.

Learning from the Field: Recent Sports Events

In June 2025, Beijing hosted what may be the most ambitious attempt at humanoid robot soccer to date. Four university teams competed in a 3-on-3 tournament where the robots were fully autonomous—no remote controls, no operator input. As reported by AP News, these robots could detect a ball from up to 20 meters away, plan routes, pass, shoot, and even stand back up after being knocked down. Tsinghua University ultimately won the final match, but every team walked away with valuable data on dynamic locomotion, visual processing, and team coordination.

The event wasn’t just entertaining—it was functionally equivalent to a multi-agent mobility and perception test. The collision handling, fall recovery, and situational awareness demonstrated by these robots closely align with capabilities assessed in proposed frameworks like ISO 25785-1, which governs mobile robots with active stability controls. Instead of a checklist of required specs, the soccer field became a living test suite.

Then came the half-marathon.

In April 2025, 21 humanoid robots joined over 12,000 human runners in the Beijing Half-Marathon. According to Wired, only six robots completed the race. The fastest, called Tiangong Ultra, finished in just under three hours. These results might sound slow, but they represent a major leap in robotic endurance. Many robots suffered from overheating, balance issues, and energy drain—exactly the kinds of performance failures that testing standards aim to prevent.

Each kilometer of that course offered more insight than any treadmill back at the lab. Roboticists learned about load-bearing under repetitive stress, adaptive gait control on varied terrain, and how robots manage thermal performance in changing conditions. These are precisely the issues engineers must address before deploying robots in environments like elder care, public infrastructure, or emergency response.

And don’t forget the martial arts. In Hangzhou, robots faced off in kickboxing-style sparring matches. As reported, these matches offered a chance to evaluate reflexes, safe collision dynamics, and force modulation. It was less about winning the fight and more about proving the robot could sense and respond to motion at human speed, without causing harm.

When the Rules of the Game Look Like Standards

What’s fascinating is how closely these competitions already resemble the framework of performance testing. Soccer robots aren’t just judged on goals—they’re measured on how well they coordinate with teammates, avoid collisions, and stay upright. In essence, they are being graded on real-time benchmarks, just like in a formal compliance test.

Many of the implicit requirements in these games—response times, endurance thresholds, recovery behaviors—mirror the metrics used in standards bodies like ASTM F45 or IEEE RAS. It’s easy to imagine how the output of these competitions could one day feed directly into the formalization of humanoid-specific standards. A stair-climbing trial in a robot decathlon could become the basis for minimum clearance specs. A fall-and-recovery event could inform safety metrics for human interaction.

This is the bridge from competition to regulation. The World Cup may not write ISO documents, but the data it produces could shape them.

Beyond Performance: Culture, Confidence, and Collaboration

The other benefit of robot sports is cultural. Watching a humanoid take a penalty shot or cross a finish line builds familiarity. It makes robots feel less like sci-fi villains and more like team players. Events like these help the public imagine what human-robot coexistence might look like. They also give regulators and policymakers concrete examples of what’s possible and what still needs work.

Competitions also break down silos. Teams from academia, industry, and startups come together in ways that typical conferences don’t always encourage. There’s real-time feedback, a common goal, and a shared spirit of experimentation. Whether it’s NimbRo from the University of Bonn or newer entrants like Booster Robotics and Noetix, these groups are testing ideas in public and learning from each other as they go.

Where This is Headed

In August 2025, China will host the World Humanoid Robot Sports Games. Events will include everything from synchronized dance to gymnastics, sprinting, and stair climbing. It’s part celebration, part competition, and part informal standardization workshop. As The Guardian noted, these events offer a window into what future humanoid capabilities might look like. They also hint at how we might measure and validate those capabilities at scale.

That’s the real win here. These robots aren’t just entertaining us—they’re helping set the foundation for responsible deployment in workplaces, homes, and public spaces. Every match is a lesson. Every stumble is a stress test. Every finish line crossed is one more step toward useful, trustworthy, and standardized humanoid robots.

So next time you see a robot miss a kick or trip over a curb, don’t laugh too hard. That misstep might just be helping define the safety protocols and design standards that ensure the next robot you meet doesn’t do the same.

Robot News Of The Week

Doosan Robotics acquires a majority stake of U.S.-based ONExia for $25.9M

Doosan Robotics has acquired an 89.59% stake in U.S.-based automation firm ONExia Inc. for $25.9 million. The Exton, Pennsylvania, company, founded in 1984, offers end-to-end automation solutions and has experience integrating systems from Doosan, Universal Robots, and FANUC.

The acquisition strengthens Doosan’s position in the North American market and accelerates its shift from hardware manufacturing to AI-driven, software-integrated robotics. ONExia brings with it 25 years of automation data and experience, particularly in end-of-line collaborative robotics such as palletizing and packaging, areas where it has seen 30% annual growth.

Doosan plans to leverage ONExia’s assets to enhance its AI capabilities and develop more intelligent, data-driven solutions. This move aligns with Doosan’s broader strategy to become a global leader in intelligent robotics, supported by increased R&D investments, a restructured R&D division focused on AI and humanoid technologies, and an Innovation Center set to open later this year.

German defense firm DIEHL has become the first foreign company to participate in Ukraine’s new “Test in Ukraine” initiative, launched by the defense tech cluster Brave1. The program allows global manufacturers to trial military technologies in real combat conditions.

DIEHL recently tested its Ziesel unmanned ground vehicle (UGV) with Ukraine’s 3rd Assault Brigade. The UGV, designed for infantry support tasks like logistics and medical evacuation, was evaluated with input from Ukrainian soldiers experienced in robotic platforms.

Digital Transformation Minister Mykhailo Fedorov highlighted the program's value in accelerating battlefield-ready innovations. DIEHL’s participation follows a memorandum of understanding with Ukraine’s Ministry of Defense to boost air defense cooperation, including a planned tripling of IRIS-T missile and system supplies.

Canada’s 4AG Robotics raises C$40 million Series B for its automated mushroom harvesting

4AG Robotics, a Canadian agtech company specializing in autonomous mushroom harvesting, has raised C$40 million in Series B funding, bringing its total to $57.5 million in just two years. The round was led by Astanor and Cibus Capital, with participation from Voyager Capital and several existing investors.

The funding will help 4AG scale production to meet rising global demand. Its AI-powered robots—already deployed in Canada, Ireland, and Australia—use precision suction grippers and computer vision to harvest, trim, and pack mushrooms 24/7. New deployments are planned for the U.S. and the Netherlands.

CEO Sean O’Connor says the company is transitioning from startup to scale-up, with deposits for over 40 additional robots. Designed to retrofit existing farm infrastructure, 4AG’s system helps reduce labor costs, improve yield, and provide real-time data.

The investment will also support expanded manufacturing in British Columbia, new hires, and the development of features like punnet packing and disease detection. With mushroom farming expected to top $70 billion by 2030, 4AG aims to lead the sector’s transformation through AI and robotics.

Robot Research In The News

Robots That Learn to Fear Like Humans Survive Better

Researchers at the Polytechnic University of Turin are developing robots that mimic human fear responses to improve safety and adaptability in unfamiliar environments. Inspired by how our brains react instinctively to threats—like ducking after a loud bang—they created a control system based on the “low road” of the brain’s dual-pathway theory, which triggers fast, emotional decisions via the amygdala.

Using reinforcement learning, their robot analyzes raw sensory data in real time to make quick adjustments, while a second algorithm translates those decisions into movement. In simulated tests, this fear-driven robot kept a safer distance from moving hazards than conventional systems.

Lead researchers Alessandro Rizzo and Andrea Usai believe this “low-road” approach could benefit applications like search and rescue or surveillance. They’re now working on adding a “high-road” system for long-term, rational planning—potentially using large language models like ChatGPT to simulate the human prefrontal cortex and expand robots’ emotional range for more adaptive behavior.

‘Bone-ified muscles’ could be robots’ next flex

Northwestern University engineers have developed a powerful new soft artificial muscle, marking a breakthrough in building lifelike, battery-powered robots. These actuators mimic human muscle function, offering both flexibility and strength, and can be integrated into animal- or human-scale robots.

To demonstrate the technology, researchers built a human-sized robotic leg using rigid plastic “bones,” elastic “tendons,” and three artificial muscles to bend its knee and ankle. The leg can kick a volleyball and operate on battery power alone, bending its knee thousands of times on a single charge.

The muscle design uses a 3D-printed structure called a handed shearing auxetic (HSA), encased in a flexible rubber housing and powered by a small motor. Each muscle can lift 17 times its weight and stretch up to 30% of its length. A built-in sensor allows the robot to “feel” its movements through changes in electrical resistance.

This innovation addresses major challenges in soft robotics, combining high force output, durability, and self-contained operation, bringing robotic systems closer to the adaptability and efficiency of human musculoskeletal systems.

Robot Workforce Story Of The Week

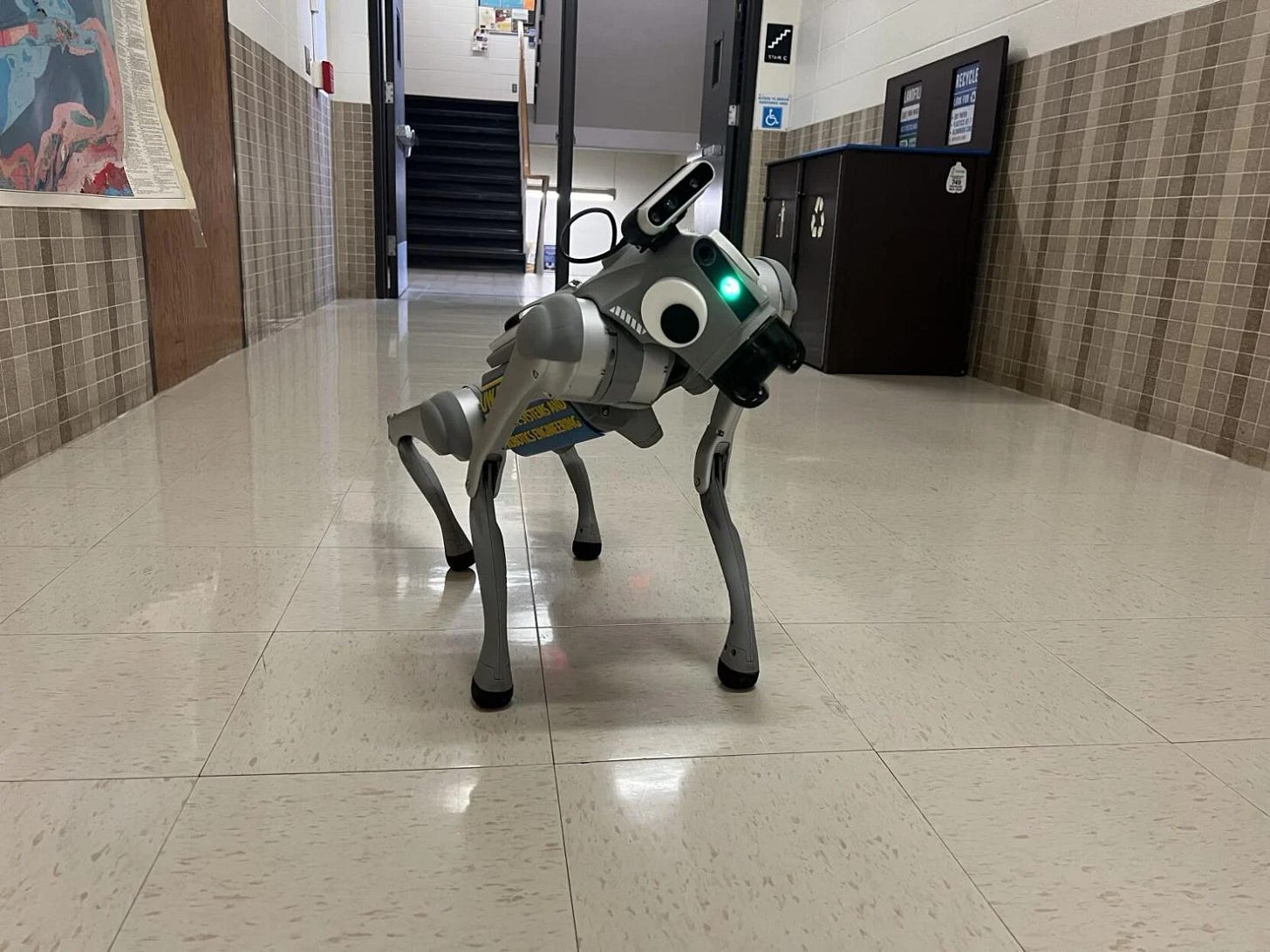

UW-Eau Claire receives robot dog for new robotics major

Starting this fall, the University of Wisconsin–Eau Claire will offer a new major in assistive systems and robotics engineering. The program will equip students with a foundation in math, computer science, and programming, focusing on robotics that support human needs in fields like healthcare, rehabilitation, and home assistance.

To support hands-on learning, students are already working with a robot dog capable of walking, climbing stairs, and using a grabber arm and cameras, giving them real-world experience in assistive robotics.

Robot Video Of The Week

Let’s get ready to rumble… with robots!

The future of combat is stepping into the ring—literally—as humanoid robots throw down in a no-holds-barred next-gen fight club at the World Artificial Intelligence Conference in Shanghai.

CGTN’s Zheng Songwu calls the action ringside, where China's Unitree Robotics is unleashing a new breed of brawlers. These bots aren’t just standing—they're jabbing, hooking, and side-kicking with a fluidity that would make seasoned fighters jealous.

It’s steel versus steel, algorithms over adrenaline, and a front-row glimpse into how far humanoid agility and reflexes have come. The message? These aren’t clunky machines—they’re the future of motion, balance, and maybe… hand-to-hand AI combat.

Fight night will never be the same.

Upcoming Robot Events

Aug. 25-29 IEEE RO-MAN (Eindhoven, Netherlands)

Sept. 2-5 European Conference on Mobile Robots (Padua, Italy)

Sept. 3-5 ARM Institute Member Meetings (Pittsburgh, PA)

Sept. 15-17 ROSCon UK (Edinburgh)

Sept. 23 Humanoid Robot Forum (Seattle, WA)

Sept. 27-30 IEEE Conference on Robot Learning (Seoul, KR)

Sept. 30-Oct. 2 IEEE International Conference on Humanoid Robots (Seoul, KR)

Oct. 6-10 Intl. Conference on Advanced Manufacturing (Las Vegas, NV)

Oct. 15-16 RoboBusiness (Santa Clara, CA)

Oct. 19-25 IEEE IROS (Hangzhou, China)

Oct. 27-29 ROSCon (Singapore)

Nov. 3-5 Intl. Robot Safety Conference (Houston, TX)

Dec. 1-4 Intl. Conference on Space Robotics (Sendai, Japan)

Dec. 11-12 Humanoid Summit (Silicon Valley TBA)

Mar. 16-19 Intl. Conference on Human-Robot Interaction (Edinburgh, Scotland)