Labor Unions and Robots - Finding A Path Forward

For most, the thought of Labor Unions embracing Automation and Robotics is a hard one to envision, but more Unions are and more will and should.

Aaron’s Thoughts On The Week

"Every advance in this half-century: Social Security, civil rights, Medicare, aid to education... one after another- came with the support and leadership of American Labor." - Jimmy Carter

It is not a stretch for many to think that when it comes to robotics and automation, labor unions are not going to be seen as a big fan. One only has to do a google search to get numerous news stories showing unions and automation at odds. However, weaved in between those stories are stories about some unions embracing automation and even some stories about how some Labor Halls are teaching robotics to their members. So maybe it is time to rethink how we see the relationship between Labor Unions and Robots, because the Unions clearly are.

The London School of Economics Study

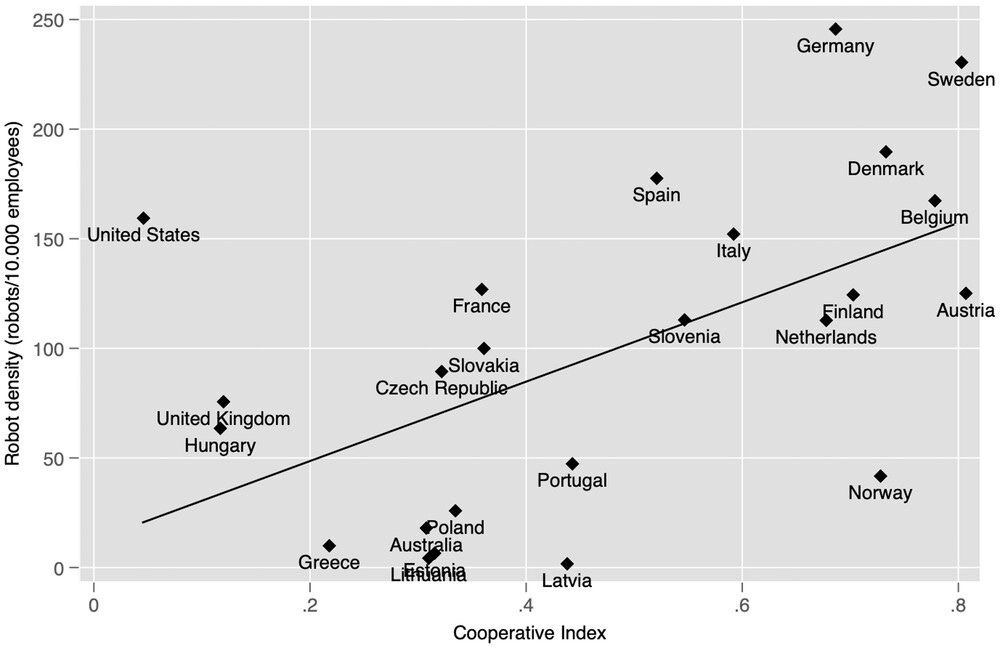

Research conducted in 2022 from the London School of Economics (LSE) has recently highlighted how trade unions and cooperative institutions could drive mutually beneficial automation in industries. The study examined automation across 25 OECD countries and found that, contrary to expectations, the presence of cooperative institutions such as works councils both encouraged industrial automation and ensured fairer outcomes for workers.

In countries with stronger labor institutions, such as Germany, automation adoption was higher compared to nations like the U.K. The study suggested that when employees support their employers' strategy and invest in retraining to complement new technology, both parties benefit. Workers in automated firms tended to experience better job security, higher wages, and safer working conditions, while businesses grew and increased headcount.

Cooperative structures, defined as things like works councils and other sector organizations, helped smooth the transition by ensuring the costs and benefits of automation were shared equitably, with some firms guaranteeing no redundancies from automation investments. This created a more collaborative environment, encouraging workers to adopt and suggest new technologies, which maximizes the return on automation.

There is strong evidence that cooperative institutions help increase the use of robots. For example, countries like Austria, Belgium, and Sweden, which have strong cooperative systems, use at least twice as many robots as countries like the UK. This finding is solid, even after controlling for other factors. So, we can conclude that cooperative institutions lead to more robotization, not less. The idea that workers would block technology that might threaten their jobs doesn't seem to be true in these cases.

The LSE study contrasted this with more liberal economies like the U.K. and U.S., where automation is often linked to declining worker shares of economic gains. It argued that automation can be beneficial for both employers and employees when all stakeholders, including labor organizations, are involved in the process.

The Tale of Automated Ports and Unions

The current labor dispute between the International Longshoremen’s Association (ILA) and port management on the East and Gulf Coasts centers on automation, not traditional issues like wages or pensions. The ILA, representing over 47,000 workers, discovered that a port in Mobile, Alabama, was using automated gates to check trucks, bypassing union workers. The union, long opposed to automation due to fears of job loss, sees this as a violation of its labor contract. Union president Harold J. Daggett has vowed to resist automation, viewing it as a threat to blue-collar jobs that can pay over $100,000 annually.

Automation, including driverless vehicles and automated cranes, has advanced rapidly, especially on the West Coast, and is seen by port operators as necessary for efficiency. However, installing new technology is costly, and resistance from unions like the ILA complicates its adoption.

While port operators claim automation creates new jobs, such as maintaining machines, the ILA remains skeptical. However West Coast ports, which have allowed automation since 2008, have seen a bigger increase in union workers over its fellow workers at the East Coast port. East Coast workers also earn less than their West Coast counterparts which also appears intensifying resistance to automation. To clarify this, though, the West Coast ports have added automation which has lead to more workers being hired and wages going higher than the “non-automated” East Coast ports.

Columbia University’s Adam Parker looked at the role of unions and automation and found that Unions that focus on workers that are very homogenous in their work, like dockworkers, are more likely to fight the push to automate. While Unions that represented diverse groups of workers like those in Restaurants and Casino businesses are more open to allowing automation in. One way that the Unions that do represent diverse groups have embraced automation is by insisting in their negotiations on avenues for workers to upskill and retrain as some of their tasks are automated. Maybe the Unions with homogenous workers should do the same.

How Unions Are Helping In Upskilling And Retraining Their Members

There have been several recent announcements by several Unions on how they are training their members on how to use automation and robotics. Here are just few.

Dusty Robotics and SMART Local 104

Unionized sheet metal training centers are continually adapting to emerging technologies to benefit members and contractors. SMART Local 104, based in Silicon Valley, has partnered with Dusty Robotics to offer specialized training on their FieldPrinter, a tool that automates layout on construction sites. This partnership aims to improve efficiency, safety, and job site coordination by teaching members how to use the technology in three stages: setup, software, and full operation.

The curriculum, developed with Dusty Robotics, offers hands-on experience, and certification will be recognized by Local 104. The FieldPrinter allows one person to handle layout tasks that traditionally required more workers and time, making it highly efficient. The training program ensures that workers can use the technology effectively, minimizing errors and maximizing productivity.

Built Robotics and International Union of Operating Engineers

The International Union of Operating Engineers (IUOE), representing over 400,000 members across the U.S. and Canada, has partnered with Built Robotics, a provider of autonomous construction solutions, in a multi-year agreement. This partnership aims to train IUOE members to manage and work alongside robotic equipment. Built Robotics will supply its autonomous guidance systems to the IUOE’s state-of-the-art International Training & Education Center (ITEC) in Houston, Texas, where members will learn to install, operate, and repair these systems under realistic job site conditions.

IUOE General President James T. Callahan highlights that this collaboration will keep members at the forefront of skilled labor, equipping them with modern technology for the 21st century. Built Robotics CEO Noah Ready-Campbell notes that robots are tools in the hands of skilled operators and sees this partnership as a way to revolutionize construction while meeting critical infrastructure needs.

Laborers’ International Union of North America (LiUNA) Embrace Exoskeletons

I need to share our organization's work in this area with our friends at LiUNA. The Laborers’ International Union of North America (LiUNA) organized an exoskeleton training event at the Ohio Laborers’ Training Center. The event aimed to promote the use of this wearable technology by providing standards and guidance. Representatives from Virginia Tech, NIST, NIOSH, ASTM Committee F48 on Exoskeletons and Exosuits, and Hilti attended the event to support this initiative.

Labor and Automation Can Work Together

Labor unions have often been seen as opposing automation, but this narrative is changing. Unions like SMART Local 104 and the International Union of Operating Engineers (IUOE) are embracing new technologies, offering training programs that prepare their members for the future of work. These partnership creates job security, higher wages, and better working conditions, proving that automation can benefit both businesses and workers when unions are involved.

The LSE Study shows that when the Union is at the table, great things can happen for everyone. The automation solutions are better, because everyone had a voice in making the automation a success from the beginning.

Unions have the opportunity to lead in the global transition to automation as the workforce continues to shrink. They can do this by focusing on upskilling, retraining, and ensuring that automation creates new opportunities for both their members and their partner companies. It’s time for labor organizations to fully embrace automation and secure a future where technology and workers thrive together.

Unions, take the lead on automation! Insist on and invest in training and upskilling programs for your members to ensure they are at the forefront of technological advancements. Let’s build a future where technology and labor work hand-in-hand for mutual benefit.

Robot News Of The Week

Siemens, Teradyne Robotics jointly develop a robotics showcase in Chicago

Teradyne Robotics and Siemens AG have partnered to create a robotics showcase at the MxD innovation center in Chicago. The showcase will offer a glimpse into the future of automation, integrating advanced robotics and AI technologies. The partnership aims to improve interoperability and streamline automation solutions in real-world factory environments.

Pickommerce secures $3.4M investment for robotic piece-picking technology

Pickommerce, an Israel-based warehouse automation company, has secured $3.4 million in funding to further develop and market its PickoBot piece-picking robot. The funding round was led by IL Ventures and included InNegev, Fusion VC, the Israel Innovation Authority, and ZIM Ventures.

PickoBot addresses the global labor shortage in the "Pick and Pack" stage of warehouse automation and features advanced computer vision, AI-powered decision-making, and multiple gripping methods. Recently deployed at Havivian Farm, one of Israel's largest organic farms, PickoBot has demonstrated its versatility by efficiently handling fresh produce packing. This investment underscores Pickommerce’s role in revolutionizing warehouse automation and meeting the growing demand for efficient, autonomous solutions in logistics.

Kiwibot acquires an ad startup to turn its delivery robots into mobile billboards

Kiwibot, the semi-autonomous food delivery robot company, has acquired Nickelytics, a Tampa-based car wrap advertising firm, for $25 million. This acquisition will allow Kiwibot to tap into the advertising potential of its robots' frequent appearances in high-traffic areas. Nickelytics specializes in car and truck wrap advertising, and digital ads in ride-sharing vehicles. The deal also involves Nickelytics CEO Judah Longgrear joining Kiwibot as a co-founder. The acquisition is expected to position Kiwibot as a market leader and support global expansion.

Autonomous robot paves the way for future fusion maintenance

A world-first autonomous robot was successfully deployed to inspect the interior of a fusion energy facility. The trial, conducted by the UK Atomic Energy Authority and the Oxford Robotics Institute, used a Boston Dynamics' Spot robot controlled by ORI's "AutoInspect" platform.

Over 35 days, the robot mapped the facility, gathered sensor data, and avoided obstacles. This milestone marks a significant advancement in making fusion energy maintenance safer and more cost-effective by paving the way for future robotic maintenance and decommissioning in hazardous environments. The success of this project could lead to broader use of autonomous robots in nuclear decommissioning, environmental clean-up, and disaster relief.

Robot Research In The News

Team develops versatile knee exoskeletons for safer lifting

Researchers at the University of Michigan have developed knee exoskeletons using off-the-shelf knee braces and drone motors to reduce fatigue during lifting tasks. The device strengthens the legs to maintain proper lifting posture, crucial in preventing workplace injuries. In tests, participants maintained better posture and lifted more quickly, just 1% slower when fatigued, versus 44% slower without the device.

The exoskeleton uses advanced sensors and software to predict and adjust the level of assistance required, making it adaptable to different tasks in real time. The estimated cost is around $2,000 per pair, and researchers are seeking commercial partners to bring the technology to market.

These hexagonal robots click together like LEGO

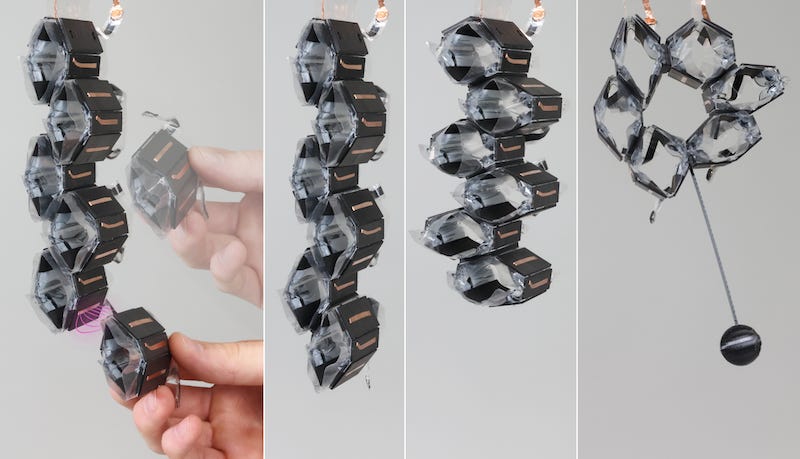

Researchers at the Max Planck Institute for Intelligent Systems in Germany have developed HEXELs, hexagon-shaped components that can be snapped together like LEGO to form robots with varying capabilities. Each HEXEL consists of lightweight glass plates and uses self-healing electrostatic muscles to change shape when activated by high voltage.

The reconfigurable design allows for the creation of different robot geometries, making it a sustainable and adaptable option, especially in resource-limited environments. The research was published in Science Robotics and highlights the potential for robots that can be repurposed on demand.

Robot Workforce Story Of The Week

Goodwin University is planning to open its 90,000-square-foot NextTech Academy in East Hartford, Connecticut, before the 2025 school year. The $85 million project will serve approximately 290 high school students, focusing on industry and technology education. The facility will feature 6,000 square feet of industrial workshops, technical classrooms, computer labs, and a cybersecurity war room. One unique addition is an astronaut training center in partnership with the Victorian Space Science Education Centre in Australia, allowing students to participate in a virtual mission to Mars.

The academy will emphasize high-tech manufacturing, particularly for aerospace and other industries in the region, offering hands-on training with equipment like CNC lathes, 3D printers, and robotics. The curriculum will include design thinking, work-based learning, and essential workplace skills like critical thinking, time management, and teamwork.

Classes will consist of 18-20 students, with around 75 students per grade. The school plans to offer paid internships and apprenticeships, preparing students for future careers. NextTech will be part of Goodwin’s network of magnet schools and located near its Pathways High School. It will include facilities like a gym, auditorium, and outdoor field.

Robot Video Of The Week

Google DeepMind released two new AI systems, ALOHA Unleashed and DemoStart, are advancing robots' ability to perform complex tasks requiring dexterous movement. While humans easily manage tasks like tying shoelaces or tightening screws, such actions are challenging for robots to master. These new AI systems aim to improve robots' interactions with physical objects in dynamic environments.

ALOHA Unleashed helps robots learn complex two-armed manipulation tasks, while DemoStart uses simulations to enhance the performance of a multi-fingered robotic hand in real-world scenarios. By allowing robots to learn from human demonstrations and translate images into actions, these systems are a significant step towards creating robots capable of performing a wider range of useful tasks.

Upcoming Robot Events

Oct. 1-3 International Robot Safety Conference (Cincinnati, OH)

Oct. 7 Humanoid Robot Forum (Memphis, TN)

Oct. 8-10 Autonomous Mobile Robots & Logistics Conference (Memphis, TN)

Oct. 14-18 International Conference on Intelligent Robots and Systems (Abu Dhabi)

Oct. 15-17 Fabtech (Orlando, FL)

Oct. 16-17 RoboBusiness (Santa Clara, CA)

Oct. 21-23 ROSCon (Odense, Denmark)

Oct. 23-26 International Conference on Social Robotics (Odense, Denmark)

Oct. 28-Nov. 1 ASTM Intl. Conference on Advanced Manufacturing (Atlanta, GA)

Nov. 22-24 Humanoids 2024 (Nancy, France)

Jan. 21-24 Intl. Symposium on System Integrations (Munich)

Mar. 4-6 Intl. Conference on Human-Robot Interaction (Melbourne)

Mar. 21-23 Intl. Conference on Robotics and Intelligent Technology (Macau)

May 12-15 Automate (Detroit, MI)

May 17-23 ICRA 2025 (Atlanta, GA)

May 18-21 Intl. Electric Machines and Drives Conference (Houston, TX)

May 20-21 Robotics & Automation Conference (Tel Aviv)

Aug. 18-22 Intl. Conference on Automation Science & Engineering (Anaheim, CA)