Let's Talk About The Robot Supply Chain

A lot of parts goes into a robot and the supply chain for those parts will make or break future robot builds and installs.

Aaron’s Thoughts On The Week

"Managing supply chains is like playing a game of chess in the dark." - Tim Cook, CEO of Apple

Having experienced the challenges of the supply chain firsthand, especially in the aftermath of the pandemic, I will always keep a close eye on it. Even when things seem to be running smoothly, I know that the smallest disruption in the chain can lead to a complete breakdown of the entire system.

So, this week, let’s take a look at the Robot Supply Chain, some of my growing concerns, and where I think there are opportunities to improve, if not harden, the Supply Chain so those of us in the Robotics Industry can keep producing for our customers.

Areas of Concern

When it comes to what is starting to concern me the most for the Robotics Supply Chain, there are three…three and a half….issues I am watching. That half one is sort of a combination of the three and we will discuss it after these core items:

Supply Chain Disruptions from Geopolitical Tensions

Labor Shortages in Manufacturing

Rising Costs of Raw Materials

Some of these have always existed, but now, with the US presidential election over and potentially a coming election in Germany, some may become bigger, and some may diminish. Time will tell. For now, though, let’s just flesh out why these are concerns right now.

Supply Chain Disruptions from Geopolitical Tensions

Geopolitical tensions have had a pronounced impact on global supply chains for long periods of time, creating challenges that ripple across industries, including robotics. With essential components, like semiconductors and rare earth materials, heavily sourced from regions such as China and Southeast Asia, disruptions due to trade conflicts, tariffs, and regional policies have added strain to an already complex supply chain landscape.

Some of these key challenges are worth paying attention to:

U.S.-China Trade Relations

As the United States has imposed tariffs and restrictions on Chinese imports in the past (and could in the coming year), and China has, in turn, responded with its own trade barriers, obtaining critical components has become more challenging and costly. This has made it difficult for robotics manufacturers, who rely on parts like sensors, processors, and batteries, which are frequently produced in China or nearby countries.

In September, the U.S. Commerce Department announced plans to ban the sale of connected and autonomous vehicles with Chinese and Russian software and hardware to protect national security and driver safety.

While Chinese and Russian software is minimally used in the U.S., there are more Chinese parts in vehicles than software. Software updates can be made more quickly than hardware replacements, which may require significant engineering and assembly line changes. As a result, the software ban will take effect for the 2027 model year, while the hardware ban will begin in the 2030 model year, or January 1, 2029, for units without a model year.

Similar bans could be proposed under the new Trump Administration and potentially accelerated.

Sanctions on High-Tech Components

The United States has implemented sanctions to regulate the export of advanced technologies, such as microchips, sensors, and AI components, to countries like China and Russia that are deemed threats to national security. These measures aim to restrict access to technology that could enhance the defense and technological capabilities of adversarial nations.

The sanctions significantly impact the robotics and high-tech sectors, where advanced chips and specialized components are vital for functions like autonomous decision-making and machine learning. By limiting exports of these components, the U.S. strives to maintain its technological advantage and prevent adversaries from advancing in autonomous systems.

These restrictions create challenges for companies in affected regions, making it harder for them to obtain the necessary components for competitive robotics and AI solutions. As a result, U.S. companies benefit from a more secure supply, positioning them favorably in the global market.

Regional Disruptions and Dependency

Natural disasters, political instability, and pandemic-related lockdowns have highlighted the risks of relying heavily on single-region suppliers. For instance, disruptions in Southeast Asia due to COVID-19 led to plant shutdowns that had a domino effect, delaying production schedules for companies worldwide. Similarly, recent tensions involving Taiwan have sparked concerns over the potential interruption of semiconductor supply, given Taiwan’s central role in global chip production.

Labor Shortages in Manufacturing

Labor shortages have placed significant pressure on manufacturing worldwide, and the robotics industry, which relies on highly skilled labor, is feeling the impact acutely. Contrary to many public opinions, you do indeed need to have people to build robots.

These shortages stem from a complex mix of factors, from lingering COVID-19 disruptions to shifting workforce expectations. Many skilled manufacturing workers have left the industry for jobs offering more flexibility or remote work, while younger generations still do not see a future in manufacturing, leaving a gap in traditional manufacturing skilled roles.

Japan is the world's leading manufacturer of industrial robots, accounting for approximately 47% of global production. Other significant producers include China, Germany, and South Korea. These countries have established robust robotics industries, contributing substantially to the global supply of industrial robots. All of them are also having major workforce issues as more workers age out than enter the industry.

While specific figures on the number of robots produced domestically are limited, the U.S. accounted for approximately 7% of the global industrial robotics market in 2023 by many estimates. This indicates that a substantial portion of robots used in the U.S. are imported from leading manufacturing countries such as Japan, China, and Germany. It is also not clear how much of the robot's manufacturing is actually just FINAL ASSEMBLY in the US, with all or a majority of the parts coming from elsewhere.

Rising Costs of Raw Materials

The rising costs of raw materials are posing significant challenges for the robotics industry, where metals such as aluminum, copper, and rare earth elements are essential in the production of components like motors, sensors, and batteries. With global demand for these materials skyrocketing, driven by industries such as electric vehicles, renewable energy, and consumer electronics, supply shortages have led to price hikes, straining manufacturing budgets and pressuring profit margins.

Aluminum

Aluminum's lightweight and conductive properties make it indispensable in the automotive and aerospace industries. In electric vehicles (EVs), aluminum is used to offset the weight of batteries, enhancing vehicle range and efficiency. The London Metal Exchange (LME) notes that the EV revolution is expected to drive aluminum demand growth, with battery electric vehicles (BEVs) utilizing aluminum to improve range and reduce greenhouse gas emissions.

Copper

Copper is essential for electrical wiring and components in EV batteries and grid infrastructure. The International Energy Agency (IEA) projects that clean energy technologies could account for over 40% of total copper demand, underscoring its critical role in the energy transition. However, copper producers have issued warnings about price volatility due to a disconnect between government mining permits and rising demand, highlighting potential delays in the energy transition without significant new copper production.

Rare Earth Elements

Rare earth elements such as neodymium and dysprosium are vital for manufacturing high-strength magnets used in motors across various industries, including robotics, wind turbines, and electric vehicles. The International Renewable Energy Agency (IRENA) emphasizes that these elements are critical for the energy transition, with neodymium being the most important in volume terms. The U.S. Department of Energy has identified dysprosium as a critical material due to its importance in clean energy technologies and potential supply risks.

Environmental and Regulatory Pressures

Mining and refining metals and rare earth elements can have significant environmental impacts, prompting stricter regulations and higher operational costs for extraction and processing. As countries enact policies to protect natural resources and reduce emissions, the cost of sourcing raw materials rises, contributing to overall price increases.

Stringent environmental regulations in the European Union have led to increased production costs for materials. For instance, the EU's Emissions Trading System (ETS) imposes costs on carbon emissions, affecting industries like cement manufacturing. As free carbon allowances decrease under initiatives like "Fit for 55," companies face higher expenses if they cannot reduce emissions, significantly impacting production costs. Similarly, the EU's Ecodesign for Sustainable Products Regulation (ESPR) sets performance and information requirements for products, aiming to improve environmental sustainability. While promoting sustainability, compliance with these regulations can increase production costs due to the need for more sustainable materials and processes.

Are We About To Have Another Semiconductor Supply Chain Issue?

This is my “half concern” I mentioned early. With more robotics getting more advance chips, one has to wonder if these three separate areas of concern could drop the heaviest on this key component the robotics industry will want and need more and more of - Semiconductors.

The semiconductor supply chain is currently experiencing a period of stabilization, with industry forecasts indicating a recovery and growth in 2024. The Semiconductor Industry Association (SIA) and the Boston Consulting Group project significant improvements in supply chain resilience in the coming years, facilitated by industry investments and incentives under the CHIPS Act. Additionally, the global semiconductor market is expected to recover this year, with an anticipated annual growth rate of 20%, driven by demand for artificial intelligence (AI) and high-performance computing (HPC).

However, potential risks remain. Natural disasters, such as Hurricane Helene, have previously disrupted critical components of the semiconductor supply chain, highlighting vulnerabilities. Geopolitical tensions and trade restrictions also pose threats to supply chain stability. While the outlook is generally positive, the industry must remain vigilant and proactive in addressing these potential challenges to maintain supply chain resilience….those of us in Robotics are counting on them to.

The Opportunites We Have

Now that I have you concerned, let me say where we have both worked to minimize these concerns and where we have opportunities to do even more to strengthen and resilient the Robot Supply Chain.

Regionalization and Nearshoring of Production

In response to persistent global supply chain disruptions, many companies are adopting regionalization and nearshoring strategies to bring production closer to end markets. By reducing reliance on long-haul shipping and concentrating on local or regional production, businesses aim to minimize the risks associated with unpredictable events—such as trade conflicts, natural disasters, and pandemics—that can significantly impact global supply lines.

The benefits are simple:

Reduced Shipping Costs and Delivery Times

Increased Flexibility and Customization

Supply Chain Resilience

Environmental and Regulatory Advantages.

In the robotics sector, regionalization has led to investments in production facilities across North America and Europe. By establishing local supply chains for robotics parts, these companies can reduce their dependence on Asian manufacturing hubs, better manage inventories, and offer faster service to clients. Additionally, with manufacturing closer to home, they can improve collaboration with local R&D teams, accelerating innovation and shortening product development cycles.

Both Yaskawa Motoman and FANUC have recently expanded their U.S. operations to meet the growing demand for automation and robotics solutions.

Yaskawa Motoman's Expansion in Miamisburg, Ohio

In August 2024, Yaskawa Motoman completed a 185,000-square-foot expansion of its headquarters in Miamisburg, Ohio. This addition nearly doubles the company's production space, enhancing its capacity to engineer, develop, integrate, and build robotic systems. The facility also provides additional space for retrofitting and rebuilding previously deployed robots and systems. This expansion represents the first phase of Yaskawa's planned $200 million investment in the United States, underscoring its commitment to growth in the Americas.

FANUC's New Campus in Auburn Hills, Michigan

In July 2024, FANUC America unveiled its new 650,000-square-foot West Campus facility in Auburn Hills, Michigan. This $110 million investment increases FANUC's footprint in Michigan to over 2 million square feet. The West Campus is designed for advanced product manufacturing and customized automation systems, featuring warehouse space for over 6,000 quick-delivery robots and tens of thousands of parts. Since 2019, FANUC America has invested over $187 million in North America, including new headquarters in Mexico and Canada. The company plans to continue its investment with the renovation of a former law school on the West Campus site to establish the FANUC Academy, an advanced automation customer training center.

Automating The Entire Supply Chain

The robotics industry is streamlining its own supply chains and integrating more robots into the supply chains of various other industries, which in turn benefits the robotics sector itself. The rapid adoption of robotics and automation is transforming supply chains across multiple sectors, enhancing efficiency, accuracy, and speed. From warehouse automation to robotic quality control, companies are incorporating robotics at different stages of their supply chains, resulting in increased productivity and reduced operational costs.

Warehouse Automation

In warehouses, robots are responsible for a range of tasks, including sorting, picking, and transporting goods. Autonomous Mobile Robots (AMRs) are particularly effective in large distribution centers, as they can navigate complex warehouse layouts independently and handle repetitive tasks. This capability allows human workers to focus on more strategic activities. For instance, Amazon Robotics operates thousands of AMRs in its fulfillment centers, resulting in faster and more efficient order processing.

Inspection, Packaging, and Logistics

Robotic systems are transforming quality control with highly accurate and consistent inspections. Unlike humans, robots can operate continuously without fatigue, identifying defects precisely and improving product quality while reducing waste.

In packaging and logistics, robots perform tasks such as verifying product integrity and ensuring proper packaging, reducing the risk of damage during transit. They also automate sorting and loading processes, optimizing the flow of goods and minimizing handling time.

By automating these stages, companies not only improve efficiency but also lower costs associated with labor and errors. Robotic systems can perform tasks faster than human workers and reduce mistakes, leading to fewer returns and more streamlined operations. Additionally, automation allows companies to adapt to fluctuating demand since robots can quickly scale operations up or down, providing the flexibility that is essential in today’s dynamic markets.

Development of Modular and Interchangeable Parts

The development of modular and interchangeable components in robotics is a promising trend for building flexible and resilient supply chains, though it is still in its infancy. Some innovative robotics companies are beginning to implement modular designs that allow for easy replacement or reconfiguration of parts. This can enhance adaptability during supply chain disruptions, but greater investment in time and capital is needed for wider adoption.

The International Organization for Standardization (ISO) has introduced the ISO 22166 series, focusing on modularity in service robots. Part 1, ISO 22166-1:2021, details requirements for creating modular frameworks and integrating modules in various environments, aiding manufacturers and designers in developing interoperable robotic systems.

Some of the advantages of Modular Design are:

Increased Flexibility in Production: By designing parts that can be easily swapped, manufacturers can adapt to component shortages more effectively. For instance, if a specific part is unavailable, a modular design might allow for a compatible alternative to be used, keeping production moving. This is particularly beneficial in industries like robotics, where complex machinery typically relies on specialized parts.

Simplified Inventory Management: Standardized modular components can streamline inventory management, as companies can stock fewer, versatile parts instead of maintaining an extensive inventory of specialized components. This reduction not only cuts costs but also reduces the risk of stockouts.

Enhanced Repair and Maintenance: Modular systems enable faster repairs and maintenance, as faulty components can be easily replaced without overhauling entire machines. This capability is essential for companies relying on robotics in their supply chain, where downtime can significantly impact operations.

Sustainability through Reduced Waste: Modular designs contribute to sustainability by minimizing waste, as parts are less likely to be discarded prematurely. Instead, worn or damaged components can be replaced individually, extending the equipment's life cycle and reducing environmental impact.

Despite these advantages, modularity in robotics is still an emerging area, and there are significant challenges. Creating widely accepted standards for modular components in robotics requires collaboration across manufacturers, which is complex and time-consuming. Furthermore, developing high-quality, interchangeable parts that meet the specific needs of different robotic systems often demands advanced engineering and precision, requiring additional R&D investments.

Increased funding in R&D, as well as industry-wide collaboration to set universal standards, could accelerate progress toward modular design. Investment in modular robotics could also enhance resilience, helping companies maintain continuity during supply disruptions and reduce reliance on single-source suppliers.

For modular design to become the norm in robotics and other high-tech manufacturing sectors, companies will need to invest in engineering and supply chain strategies that prioritize flexibility and adaptability. Government grants and industry partnerships could play a crucial role in fostering this development, especially as supply chain resilience becomes an economic priority.

So Where Are We In The Robotics Supply Chain?

I would say we are currently pretty stable, all things considered with a few exceptions, but to say there are dark skies on the horizon is not an understatement. It is clear we were not ready at all for the supply chain shock that came after the pandemic, but we have learned some lessons from that and are executing on making the needed changes.

We definitely need more reshoring and nearshoring of the robot supply chain to the final end users of those robots, but that will require both investment and demand to justify that investment. There is definitely a need for that not only in the United States but everywhere the robotics industry is.

For items that must be sourced from a single location, because that is simply the only place they are, we will need to get creative. We will need to either find new sources outside of the existing ones or find alternatives much faster.

Potential manmade threats will need to be solved by people - plan and simple. The Robotics Industry will need to advocate for itself where it can and make the case that these manmade problems will impact them and their own workforce. This will need to be done with facts and data, that is where it could get tricky.

So, for now, keep building those beautiful robots. However, stay vigilant for those dark skies, and let’s avoid them together.

Robot News Of The Week

Physical Intelligence raises $400M for foundation models for robotics

Physical Intelligence recently announced a $400 million funding round to advance its AI technology aimed at equipping robots with generalized skills. Unlike traditional AI models that require extensive examples to learn specific tasks, Physical Intelligence's approach focuses on creating a "generalist brain" that can control any robot, not just a single type. Co-founder and CEO Karol Hausman describes this as a revolutionary step towards more adaptable and easily programmable robots.

The company’s initial release, π0, is a prototype model that integrates vast multi-task and multi-robot data with an innovative network architecture. This development represents a significant stride in creating versatile robots capable of complex tasks that have historically posed challenges for AI, such as folding laundry or cleaning a table. Physical Intelligence believes π0 is an early but promising milestone toward achieving general-purpose robotic intelligence.

Ulysses is using robots to restore seagrass populations

Seagrass, despite covering just 0.1% of the ocean floor, plays a vital role in supporting marine life, filtering water, and capturing carbon. However, it’s being lost at a rate of 7% annually due to climate change. Ulysses Ecosystem Engineering aims to restore these essential meadows through robotics. Their autonomous robot, designed to plant seagrass seeds efficiently, can speed up restoration by 100x compared to traditional methods and at a fraction of the cost.

Founded in early 2024 by Jamie Wedderburn, Akhil Voorakkara, and others, Ulysses emerged from an initial prototype and is backed by a $2 million pre-seed round led by Lowercarbon Capital. The company has generated nearly $1 million in revenue and partners with government agencies in Florida and Australia for large-scale projects. They’re now expanding their robot’s capabilities to include seed harvesting from approved beds for replanting.

Looking ahead, Ulysses envisions their tech going beyond seagrass restoration to coastal management and security, with a goal to manage hundreds of kilometers of coastline within five years.

23-Year-Old Invents Wearable Robot to Preserve Indigenous Languages

Danielle Boyer, a 23-year-old Ojibwe robotics engineer, designed her first robot at 17 and has since become a passionate advocate for accessible tech education for Indigenous youth. Her first creation, EKGAR (“Every Kid Gets a Robot”), is a $20 remote-control car kit made from 3D-printed recycled plastic, helping Indigenous students gain technical skills. She’s shipped over 11,000 EKGAR kits for free.

Boyer’s second creation, SkoBot, is a small, wearable robot that helps teach the endangered Ojibwe language, Anishinaabemowin. Designed with cultural significance, the SkoBots respond with phrases like “boozhoo” (hello) and include traditional animal designs. Her nonprofit, STEAM Connection, distributes these kits at no cost, allowing students to build the robots themselves and learn hands-on engineering skills.

Growing up in Sault Ste. Marie, MI, Boyer faced financial and gender barriers in STEM, including being the only girl and Indigenous student in her high school robotics club. Now, she champions Indigenous representation in STEM fields and inspires others to overcome obstacles and embrace their potential.

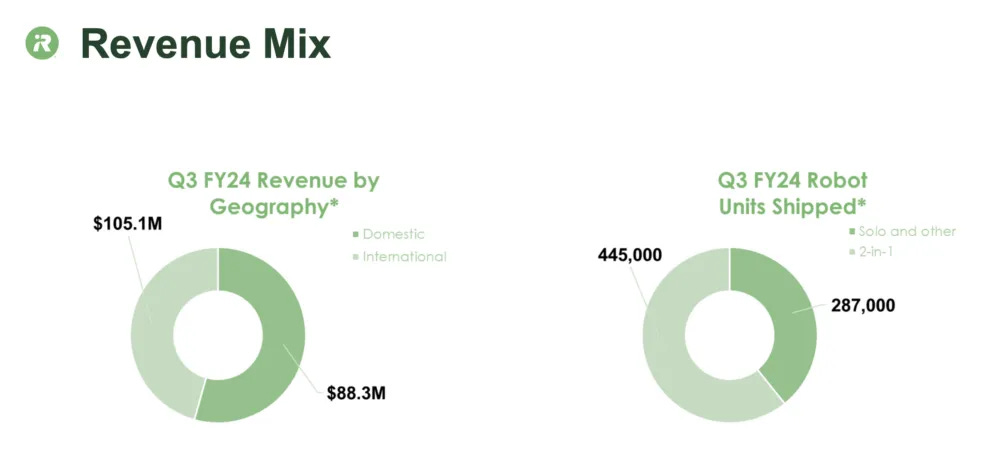

iRobot lays off another 105 employees

iRobot, maker of the Roomba, is laying off another 105 employees, representing 16% of its workforce, as part of ongoing restructuring. Since the start of 2024, the company has cut nearly half of its global staff due to financial struggles driven by a failed acquisition attempt by Amazon, increased competition from cheaper alternatives, and limited success in diversifying its product line.

Despite iRobot's revenue rising to $193.4 million in Q3 2024, the company faces headwinds in international markets and expects revenue between $175 million to $200 million for Q4. CEO Gary Cohen emphasized a new strategy, "iRobot Elevate," aiming to leverage its strong brand and cut operating costs, targeting a return to growth in 2025. CFO Julie Zeiler noted cautious optimism for a stronger second half in 2025 as new products ramp up.

Robot Research In The News

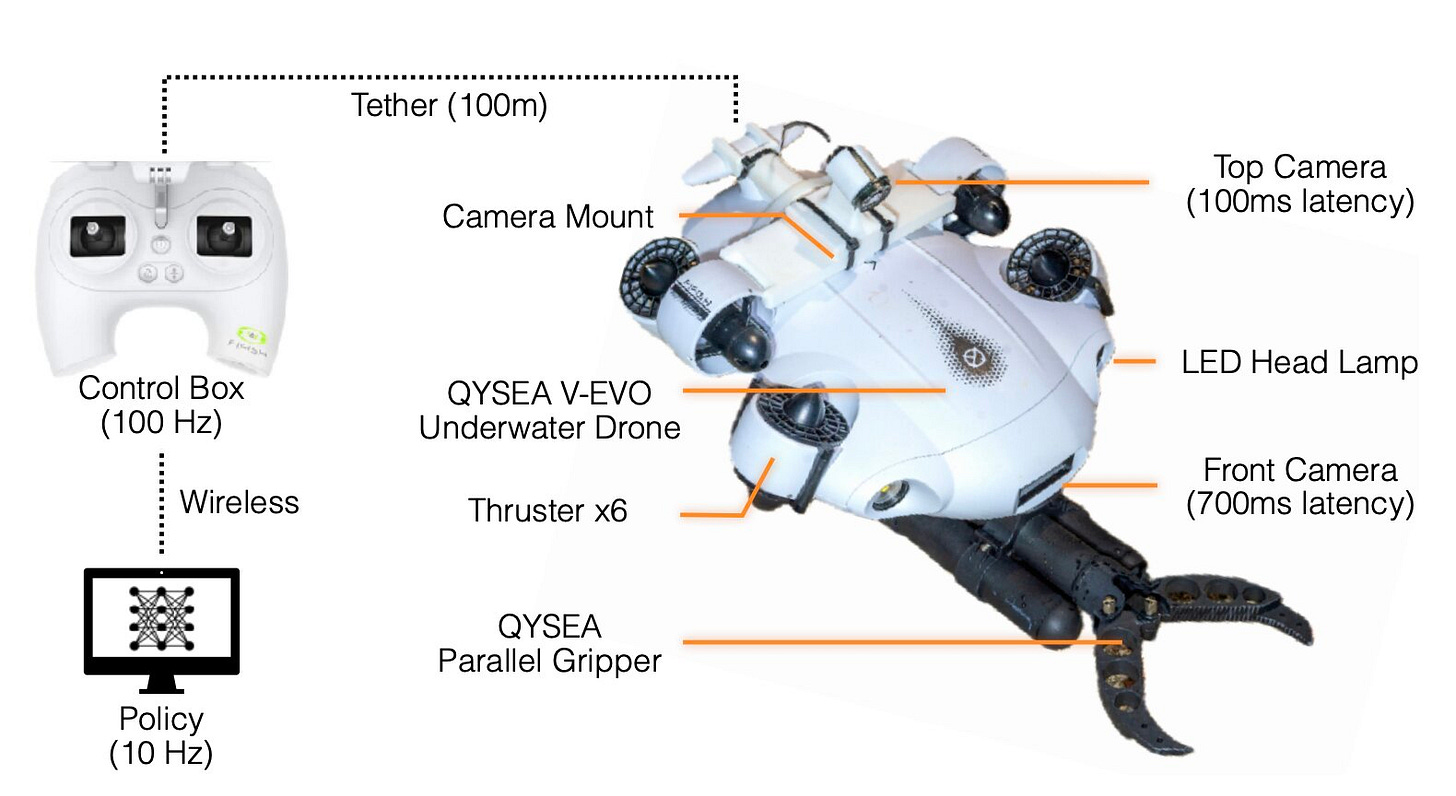

Aquatic robot's self-learning optimization enhances underwater object manipulation skills

Columbia University researchers have developed AquaBot, an autonomous underwater robot that can perform object manipulation tasks, overcoming the challenges of underwater dynamics. AquaBot, built on the QYSEA V-EVO underwater drone, uses a parallel jaw gripper and dual cameras to handle tasks like grasping rocks, sorting trash, and retrieving objects resembling human bodies.

The robot's control system is trained through two stages: first, it learns visuomotor skills from human demonstrations to handle unexpected underwater conditions, then it uses self-guided optimization to refine its speed and effectiveness. Real-world tests showed AquaBot completing tasks 41% faster than human operators.

AquaBot’s hardware and software are open source, allowing others to further develop it. Potential applications include underwater search and rescue, seabed cleaning, and other environmental missions.

AI-driven mobile robots team up to tackle chemical synthesis

University of Liverpool researchers have developed AI-powered mobile robots that perform chemical synthesis research with speed and efficiency comparable to human researchers. Described in Nature, these 1.75-meter robots autonomously execute, analyze, and plan chemical reactions across fields like drug discovery and photochemistry, significantly accelerating decision-making in exploratory chemistry.

Led by Professor Andrew Cooper, the robots address the time-consuming task of deciding next steps based on analytical data, a challenge in exploratory chemistry due to its unpredictable nature. AI logic enables instant decisions on progressing reactions, contrasting with the hours it might take human chemists.

Future applications may include drug synthesis and materials for CO₂ capture. This scalable approach could transform large-scale labs, building on Cooper’s earlier work with robotic chemists.

Robot Workforce Stories Of The Week

A collaboration to bring undergraduate robotics courses to more universities

For the fall 2023 and winter 2024 semesters, students from Howard University, Morehouse College, and Berea College are taking online Robotics 102 courses with University of Michigan students. This is part of the Distributed Teaching Collaborative, an initiative that began in 2020 to provide advanced robotics courses to students who lack access at their own universities. The goal is to enhance instructional quality and prepare students for potential graduate studies in robotics at U-M or elsewhere.

How the Robotics and Automation Summer School Can Kick-start Your Career in Cutting-Edge Robotics

Explore the Robotics and Automation Summer School (RASS) at Los Alamos National Laboratory, where students from top universities engage in advanced robotics projects in artificial intelligence, automation, and machine learning. As a premier program for future leaders in robotics, RASS offers unique opportunities to collaborate with leading scientists. If you're passionate about robotics, learn how RASS can launch your career in innovation.

Robot Video Of The Week

Physical Intelligence (π) has launched π0, a groundbreaking generalist robot policy model that expands the possibilities of physical intelligence. Trained on a vast dataset of robot interactions and utilizing advanced vision-language pretraining, π0 enables robots to perform complex tasks—such as folding laundry and autonomous assembly—with minimal fine-tuning. This is just the start of our mission to create foundation models that let robots execute any task on command. Join us as we explore the challenges we've overcome and the future of robot foundation models.

Upcoming Robot Events

Nov. 12-14 Intl. Symposium on Safety, Security, & Rescue Robotics (New York City)

Nov. 22-24 Humanoids 2024 (Nancy, France)

Dec. 11-12 Humanoid Summit (Mountain View, CA)

Jan. 7-8 UK Robot Manipulation Workshop (London, UK)

Jan. 7-10 CES (Las Vegas, NV)

Jan. 21-24 Intl. Symposium on System Integrations (Munich)

Apr. 23-26 RoboSoft (Lausanne, Switzerland)

Mar. 4-6 Intl. Conference on Human-Robot Interaction (Melbourne)

Mar. 21-23 Intl. Conference on Robotics and Intelligent Technology (Macau)

Apr. 30-May 1 Robotics Summit (Boston, MA)

May 12-15 Automate (Detroit, MI)

May 17-23 ICRA 2025 (Atlanta, GA)

May 18-21 Intl. Electric Machines and Drives Conference (Houston, TX)

May 20-21 Robotics & Automation Conference (Tel Aviv)

June 30-July 2 International Conference on Ubiquitous Robots (College Station, TX)

Aug. 18-22 Intl. Conference on Automation Science & Engineering (Anaheim, CA)