Manufacturers' Growing Technology Regret

48% of manufacturers have buyer’s regret from a recent tech purchase

Aaron’s Thoughts On The Week

“You can't always get what you want, but if you try sometimes, you'll find you get what you need.” — The Rolling Stones

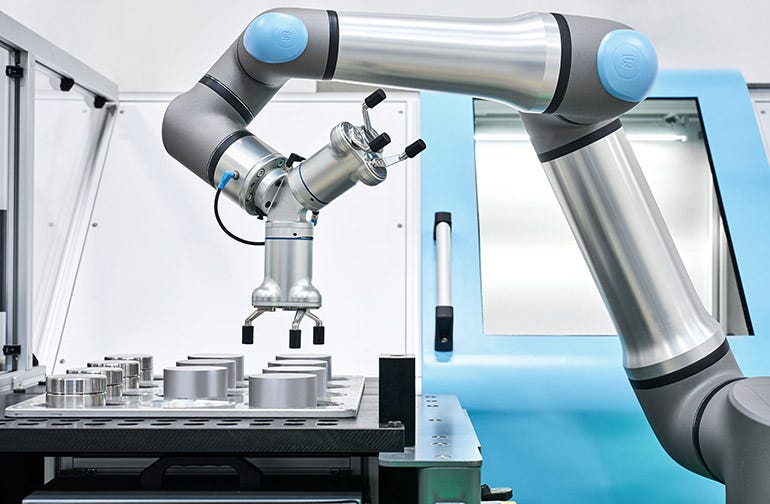

Earlier this week, Universal Robots’ Will Healy posted a very interesting LinkedIn post in which he cited a recent Gartner Digital Market Report about recent technology purchases and growing “buyer remorse.” Now, the report focused on software, but it points to what could become a growing problem for physical automation and robotics installations going forward.

In Will’s LinkedIn post, he highlights some of the key findings in the Gartner report.

48% of manufacturers have buyer’s regret from a recent tech purchase

Most often, regret is driven by higher-than-expected costs (38%)

Implementation issues (35%)

Poor functionality (34%) is another product-related factor that disappoints buyers.

They noted that the technology needed to be more advanced and had fewer features than needed.

I can confidently say that I am starting to see similar numbers as I talk to more firms about their recent automation and robotics installations. Thinking about it, I should do a formal survey using this Gartner report as inspiration (and partial benchmarking). #FurtureProject

I’ve seen way too many firms, especially manufacturers, go full steam in on a project that will if it works, solve a ton of issues for them. The key, though, is it has to work, and it has to work to what was expected. I’ve done a lot of automation and robotic projects, and I can count on one hand one finger a project that hit every expectation. So we have some firms that are dropping hundreds of thousands, if not millions, of dollars on one of their first automation/robotic projects. It won’t take much for that of a big gamble to have some sort of disappointment attached to it. Now the question becomes if it is a “well, it would have been nice if that happened” regret or if someone or a group of people are looking for new jobs regret.

My stance for every firm regardless if they are a billion dollar Fortune 500 company or a one-man shop, start with the low hanging fruit projects and build your confidence with the new technology. Get those quick wins and start showing how these small installs are changing the total operation for the better versus trying to change the entire operation with a All-or-Nothing approach.

Case in point: Palletizing Robots. Any facility that is building up pallets, especially of the same SKU type, should have a robot do it. Robotic palletization is an established technology. Most robot OEMs have palletization pre-programmed into their software it is so common. In most cases, a front line employee can “program” a robot to palletize the same box type over and over again. Also, no one wants to be building pallets all day. So it is an easy first win that will show and ROI quickly and make employees happy at the same time.

The good news is that the Gartner report gave those they surveyed a way to list out what they would do differently….and they put it in a cool graphic. Again the focus was on software.

All of these would apply to automation and robotics. I would say all firms should do their homework on two of them before any projects: Supplier Risk Assessment and Stakeholder Engagement.

In my former life as an end user of robotics, I had a full list of my suppliers, and all of them had a risk assessment done on them. Now, being with a Fortune 500 company, I have a lot more resources to do that. However, asking some key questions like how many installs of this nature have they done and how they will address issues as they arise should be on everyone’s selection criteria. Some would call it “doing your due diligence,” and when it comes to technologies that are sometimes not fully proven out, you better make sure you are partnering with a company that can deliver on what you want.

As for stakeholder engagement, I’ve encountered way too many firms that don’t understand everyone who will be impacted by the automation/robotics project. I’ve been in some meetings where no one from Operations (the ones that will be using the robot) is in the room. This is a huge red flag. But then there are the other overlooks, like not including Maintenance or even the Cleaning Crew. A sad fact is that most deaths involving industrial robots involve maintenance and cleaning workers doing something off-cycle in the robot cell. So not having all of the stakeholders involved from Day One can indeed turn deadly.

More robots and automation are coming to our workplaces. This means there will be more regret that can make or break the future of more robots and automation coming to that firm. It is going to take everyone from Robot OEM, Robot Integrator, and Robot End User to be on the same page from the very start. This will not eliminate the risk of a project going sideways, but it will lower that risk much more than not.

Not only could your job depend on it, but your very life or the life of someone else could be on the line.

Robot News Of The Week

iRobot terminates deal with Amazon, laying off 31% of staff

iRobot Corp. and Amazon.com Inc. have terminated their planned acquisition, citing "undue and disproportionate" regulatory scrutiny. David Zapolsky, senior VP and general counsel at Amazon expressed disappointment and cited regulatory hurdles that impede innovation and deny consumers faster innovation and competitive prices.

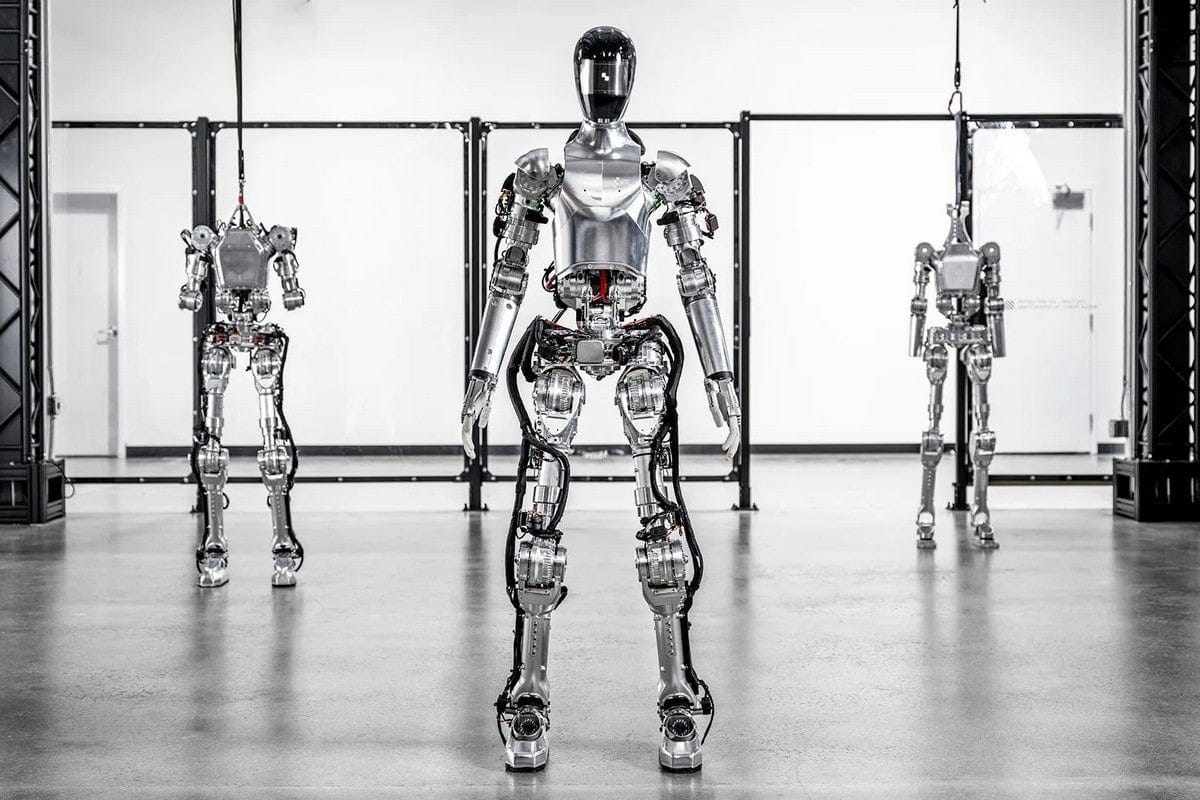

Microsoft and OpenAI may invest up to $500 million in Figure AI, a startup focused on deploying autonomous humanoid workers worldwide. The funding could value Figure AI at $1.9 billion, potentially making it the first humanoid robotics unicorn. The company has already signed a partnership with BMW to trial its robots in a South Carolina factory. The market for robotics is expected to be worth $3 trillion by 2050 and is poised to be the "biggest thing in 2024" aside from LLMs.

Teradyne robotics group earns $375M in 2023

Teradyne's robotics group generated $375M in revenue in 2023, down from $404M in 2022. Universal Robots (UR) generated $304M in revenue in 2023, a 7% YoY decline but ended the year on a high note with the largest revenue quarter ever in Q4, attributed to the demand for its UR20 and UR30 cobots.

Robot Research In The News

Avocado robot swings its way to unexplored treetops

Avocado is an innovative robot designed to explore the dense canopy of tropical rainforests. It has a robust housing similar in shape to the green fruit and is equipped with technology that enables it to navigate through the treetops autonomously. The robot is one of the latest inventions in the field of environmental robotics and will collect data for researchers about this hard-to-reach habitat.

Robot trained to read braille at twice the speed of humans

Researchers from the University of Cambridge developed a robotic sensor utilizing AI techniques that can read braille at double the speed of most humans. The robot reads at 315 words per minute with almost 90% accuracy. The team used machine learning algorithms to train the robot to slide over braille lines, making it an ideal test for the development of robot hands or prosthetics with comparable sensitivity to human fingertips. This could help in solving the significant engineering challenge of reproducing the sensitivity of human fingertips in an energy-efficient manner.

A robot with living muscles walks through water

A tiny, bipedal robot that combines muscle tissue with artificial materials can walk and turn by contracting its muscles.

Robot Workforce Stories Of The Week

Girls Build Award-Winning Robot, Get STEM Inspiration

Last week, four girls from North Carolina visited the Pentagon along with the large robot they built. They were there to brief European participants of the State Department's International Visitor Leadership Program on how to increase inclusivity in Science, Technology, Engineering, and Mathematics (STEM) fields.

Students given hands-on robotic surgery experience

Pupils at Malmesbury School used surgical robots as part of a careers day. The robot was loaned by CMR Surgical and it was aimed at inspiring students to consider careers in healthcare and engineering. Mr. Anwar Owais, Consultant General and Colorectal Surgeon at GWH organized the day and said the robots have already made a difference to patients and should improve vision, reduce pain, and speed up recovery.

Robot Video Of The Week

Researchers at Carnegie Mellon University and ETH Zürich have introduced a new learning-based control framework called Agile But Safe (ABS), enabling quadrupedal robots to move swiftly without collisions in cluttered environments. ABS is based on two policies: an agile policy and a recovery policy that work together to achieve high-speed and collision-free navigation. Once trained, these modules can be directly deployed in the real world with onboard sensing and computation, allowing for high-speed and collision-free navigation in confined indoor and outdoor spaces with static and dynamic obstacles.

Research Paper: https://lnkd.in/eQNyHtH3

Project Page: https://lnkd.in/e-JBMkmU

Upcoming Robot Events

Mar. 11-14 ACM/IEEE International Conference on Human Robot Interaction (Boulder, CO)

Mar. 11-14 MODEX (Atlanta, GA)

Mar. 25-27 International Conference on Industrial Technology (Bristol, UK)

Apr. 7-10 Haptics Symposium (Los Angeles, CA)

Apr. 14-17 International Conference on Soft Robotics (San Diego, CA)

May 1-2 The Robotics Summit & Expo (Boston, MA)

May 6-9 Automate (Chicago, IL)

May 13-17 IEEE-ICRA (Yokohama, Japan)

July 2-4 International Workshop on Robot Motion and Control (Poznan, Poland)

July 8-12 American Control Conference (Toronto, Canada)

Oct. 1-3 International Robot Safety Conference 2024 (Cincinnati, OH)

Oct. 8-10 Autonomous Mobile Robots and Logistics 2024 (Memphis, TN)

Oct. 16-17 RoboBusiness (Santa Clara, CA)

Oct. 28-Nov. 1 ASTM Intl. Conference on Advanced Manufacturing (Atlanta, GA)

Nov. 22-24 Humanoids 2024 (Nancy, France)