Robot Density: China Rising, US Lagging

The latest Robot Density Report was released by the IFR and it wasn't very shocking

Aaron’s Thoughts On The Week

"A goal without a plan is just a wish."– Antoine de Saint-Exupéry

This week, we received the latest Robot Density Report from the International Federation of Robotics (IFR). The robotics industry anticipates this report each year because it shows the annual global growth in Robotics and where it is happening country by country. The IFR takes a bit of time to put the report together, so it always looks one year before the year of its release. So, the data for this new report looks at 2023.

You may ask why. The IFR is looking at actual install numbers, not sales data. This is important because it allows the report to show a country’s actual install base and whether it is growing or not. If the report relied on only sales data, it may look like a country is growing when all it is doing is switching out old robots for new ones, which doesn’t really mean it is growing its base of robots; it is just buying robots.

Now, the IFR does release sales figures throughout the year, and those reports give us an idea of what is happening, but until the Density Report drops, we will not better understand growth versus replacement.

For this report, I am not seeing anything very shocking when we look at the previous reports and the treadlines that were emerging. We saw China was rising quickly and that the US was continuing to fall down the list. With this new report, while not shocking, it should be a wake up call for some countries.

The Report Itself

According to the World Robotics 2024 report by the International Federation of Robotics (IFR), global robot density in factories has hit a record 162 robots per 10,000 employees in 2023, more than double the 74 units recorded seven years ago. This surge reflects the rapid adoption of automation across the manufacturing industry.

Regional Insights:

Europe: Leads with a density of 219 units, driven by countries like Germany, Sweden, and Denmark, all in the global top 10.

North America: Density rose to 197 units, with the U.S. ranking 11th globally at 295 units.

Asia: Density climbed to 182 units, with standout performances from Korea, Singapore, China, and Japan.

Top Countries in Robot Density:

Korea: 1,012 units per 10,000 employees, driven by its electronics and automotive sectors.

Singapore: 770 units, achieving high density due to its small manufacturing workforce.

China: 470 units, doubling its density in just four years and overtaking Germany and Japan.

Germany: 429 units, maintaining steady growth with a 5% CAGR since 2018.

Japan: 419 units, growing 7% annually, thanks to its leadership in robot manufacturing.

This rapid increase highlights the global shift toward automation, with Asia leading the charge and countries like China making remarkable progress.

Countries With National Robotics Plans Continue To Grow

It is no secret that the countries in the Top 5 now have what are clear robotics and automation plans. From China’s Made in China 2025 to Germany’s Industrie 4.0, these national strategies appear to be showing in the numbers.

It is also the growing reason that the US is falling further behind. Even though we have a great team from the robotics industry develop the US Robotics Roadmap every four years, we don’t see much when it comes to federal coordination of efforts on a scale that the Top Five countries have.

While the Manufacturing USA Institutes and the CHIPS Act are providing much assistance to growing the US’s industrial robot base, it is clear from this latest IFR report that others are doing much better because they are doing something about it. For the US to return to the Top Ten, significant investment and key planning will be needed. Implementing many of the items in the US Robotics Roadmap would help, but that will require the US politicians to actually do something about that. Let’s say I don’t hold out much hope.

In 2022, the US was at 285 robots per 10,000 workers. For 2023, the number when up to 295 robots per. So a 3.5% growth in the install base. We really need to be closer to 5% if we every hope of returning the Top Ten. So hopefully we will see where 2024 lands next year when the IFR publishes next year’s report.

Not Much More To Say

Due to traveling this week, I haven’t been able to dig more into the IFR report. However, I think I will see more of the evidence that countries that actually have solid national plans for robotics and automation will continue to grow and move up this list.

The US really needs to wake up and start making bold plans, especially since we are facing the same aging demographics and shrinking workforces as the other countries on the list. We need to make significant investments to help companies automate dull, dirty, and dangerous tasks and train their existing workforces to leverage robotics and automation to their maximum potential. Until US politicians agree and actually commit to that type of what appears to be bold leadership, then expect the US to fall to the middle of the pack in the coming years and continue to lose leadership in the field of robotics industry that sees it as a part of their national strength.

Robot News Of The Week

Collaborative Robotics unveils Proxie mobile manipulator

Collaborative Robotics Inc. has officially introduced its Proxie mobile manipulator, marking the first public reveal of the robot since the company’s founding in 2022 by Brad Porter.

Designed specifically for warehouse applications, Proxie focuses on optimized kinematics tailored to warehouse workflows, diverging from humanoid designs to better meet operational needs.

Supply Chain AI Mobile Robots Ready for Business

Gartner's latest Hype Cycle report highlights rapid advancements in mobile robotics for supply chains, predicting maturity for technologies like autonomous mobile robots (AMRs), collaborative picking robots, and robotic goods-to-person systems within the next 2-5 years. These innovations have moved beyond the Trough of Disillusionment, entering the Slope of Enlightenment, signaling growing enterprise benefits and wider adoption.

Emerging technologies such as AI-enabled drones for data collection and inspection are also gaining traction. These tools, utilizing RFID and AI vision, streamline inventory, inspection, and surveillance tasks and are nearing the Peak of Inflated Expectations with potential benefits expected within 5-10 years.

Notably, humanoid robots have entered the Innovation Trigger phase, showing early promise in transforming supply chains. Their human-like adaptability could enhance operations by dynamically shifting tasks without special programming. However, widespread adoption in complex industrial environments is projected to be over a decade away.

Pickle Robot gets orders for over 30 unloading systems plus $50M in funding

Pickle Robot Co. has raised $50 million in Series B funding to advance its autonomous truck-unloading robots, a solution targeting the dull, dirty, and dangerous tasks in logistics. In Q3, the company secured orders for 30+ robots from six customers, set to deploy by mid-2025.

Founder and CEO AJ Meyer highlighted the impact of "Physical AI" in streamlining truck unloading, enhancing productivity, and addressing labor shortages. The funding will support product innovation and business growth, enabling Pickle Robot to drive efficiency and safety in distribution centers globally.

Robot Research In The News

Newly developed robot can play the drums, listen and learn

The ZRob robot, developed by Mojtaba Karbasi at the University of Oslo's RITMO Center, is a groundbreaking creation blending AI and bio-inspired design. Equipped with a flexible, spring-assisted arm mimicking a human wrist, ZRob excels at playing drums with precision and sensitivity. It even achieves rhythms beyond human capability when multiple units perform together.

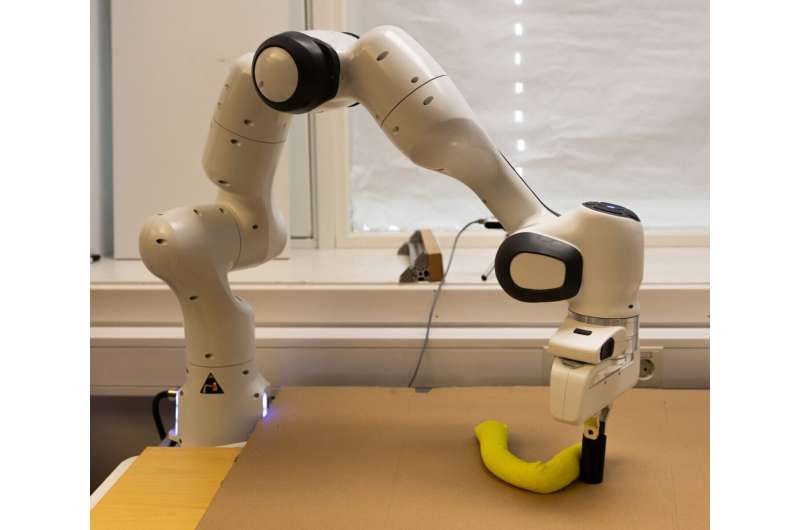

AI allows new robot to manipulate soft and pliable objects

The Bifrost robot, developed by researchers in Norway, is breaking new ground in robotic manipulation of soft, pliable objects, using AI, tactile abilities, and machine vision. Designed with a flexible "finger" and articulated arm, the robot demonstrates skills crucial for industries like food processing, particularly seafood.

Robot Workforce Story Of The Week

South Bend Community School Corporation receives grant of over $100,000 for the Robotics Program

Robot Video Of The Week

Figure AI’s humanoid robot ‘speeds up BMW production by 400%’

Figure AI and BMW have announced groundbreaking upgrades to the Figure 02 humanoid robot, now operational on a production line. With a 400% speed boost and a 7x improvement in task success, the Figure 02 has advanced into a fleet-ready, autonomous system.

A recent video showcases the robot completing up to 1,000 placements daily, highlighting its impressive capabilities. Brett Adcock, Figure's founder and CEO, emphasized that these results will continue improving with expanded deployment, enhanced data collection, and refined AI models.

Upcoming Robot Events

Nov. 22-24 Humanoids 2024 (Nancy, France)

Dec. 11-12 Humanoid Summit (Mountain View, CA)

Jan. 7-8 UK Robot Manipulation Workshop (London, UK)

Jan. 7-10 CES (Las Vegas, NV)

Jan. 21-24 Intl. Symposium on System Integrations (Munich)

Apr. 23-26 RoboSoft (Lausanne, Switzerland)

Mar. 4-6 Intl. Conference on Human-Robot Interaction (Melbourne)

Mar. 21-23 Intl. Conference on Robotics and Intelligent Technology (Macau)

Apr. 30-May 1 Robotics Summit (Boston, MA)

May 12-15 Automate (Detroit, MI)

May 17-23 ICRA 2025 (Atlanta, GA)

May 18-21 Intl. Electric Machines and Drives Conference (Houston, TX)

May 20-21 Robotics & Automation Conference (Tel Aviv)

June 30-July 2 International Conference on Ubiquitous Robots (College Station, TX)

Aug. 18-22 Intl. Conference on Automation Science & Engineering (Anaheim, CA)