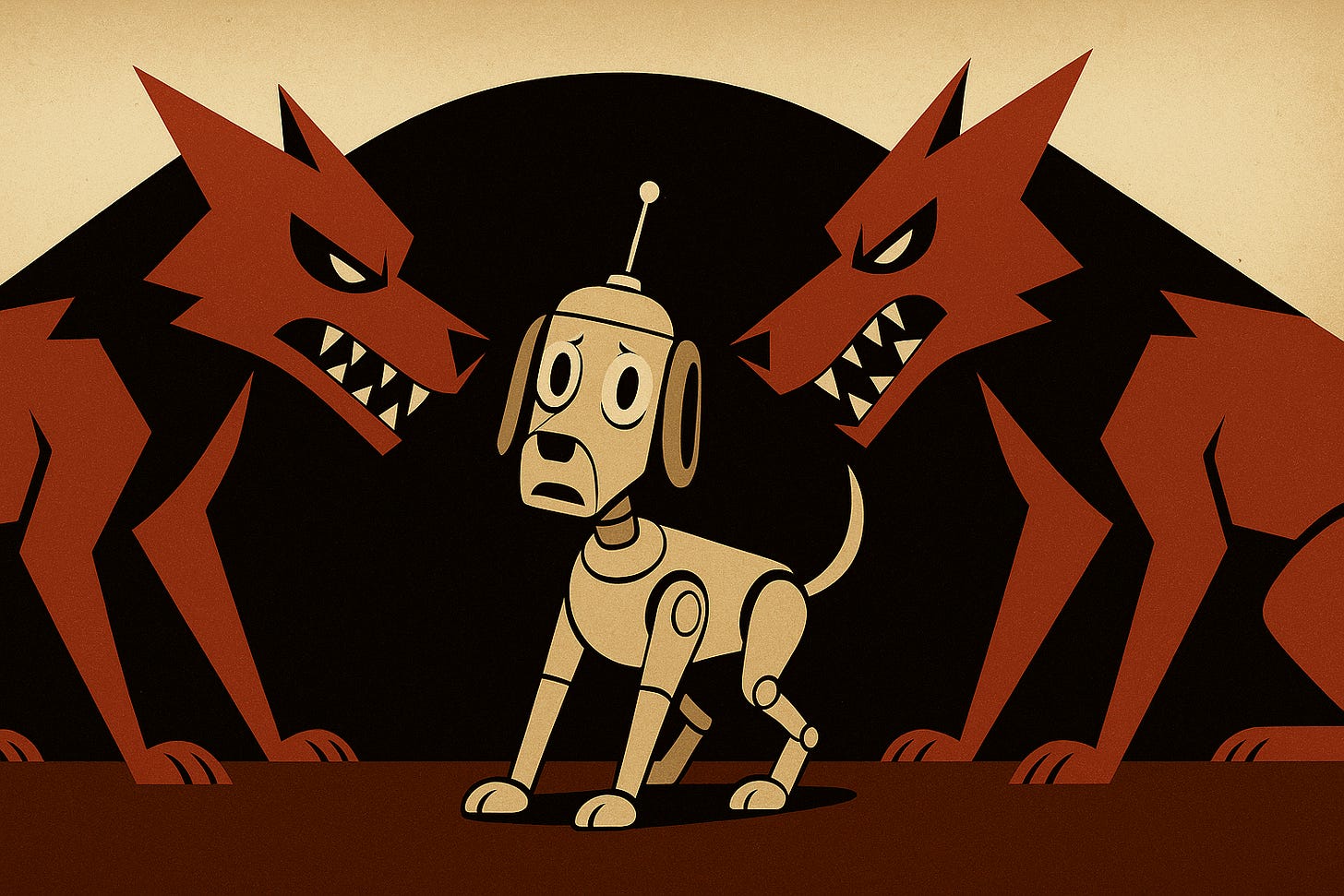

Robot Wolves vs. Robot Dogs: Semantics and the Future of Military Robotics

Semantics, symbolism, and the blurred line between civilian and combat robotics.

“Words are, of course, the most powerful drug used by mankind.” — Rudyard Kipling

When China unveiled its latest military arsenal during the V-Day parade in Beijing, one of the most talked-about technologies wasn’t a missile or a drone—it was the debut of so-called “robot wolves.” These four-legged machines marched before world leaders, including Vladimir Putin and Kim Jong Un, and state media claimed they were designed for frontline reconnaissance, supply delivery, and even precision strikes.

The terminology raised eyebrows. After years of seeing “robot dogs” like Boston Dynamics’ Spot and Unitree’s Go1 deployed in civilian and industrial environments, why suddenly call a nearly identical quadruped robot a wolf? Is Ghost Robotics Vision 60 robot a “robot wolf” then?

The Canine Divide: Dogs vs. Wolves

“Robot dogs” have long been marketed as approachable, even friendly. Spot herds sheep in New Zealand, Unitree’s robots entertain crowds with backflips, and Ghost Robotics partners with police forces for inspection and patrol. Their framing as dogs matters—they are man’s best friend, loyal and helpful.

“Robot wolves,” by contrast, signal something very different. Wolves evoke aggression, pack hunting, and danger. By rebranding the same robotic form factor as wolves, militaries draw a sharp line between civilian utility and battlefield menace. In effect, dogs belong in warehouses and shopping malls; wolves belong on the frontlines.

A Matter of Semantics—or Something More?

Is this distinction purely linguistic sleight of hand? Perhaps. However, history shows that names carry significant weight in shaping the public perception of new technologies. The U.S. military once referred to drones as “unmanned aerial vehicles,” a clinical term that downplayed their offensive capabilities, before the term “drone” entered widespread usage with its more ominous undertones.

By adopting wolf, Chinese state media might be engaging in a similar rebranding strategy: normalizing quadruped robots as weapons while distancing them from their cuddlier civilian cousins. The irony, of course, is that the hardware itself—actuators, sensors, and control systems—is not dramatically different.

Global Trends in Quadruped Robotics

China is not alone in militarizing four-legged robots. The U.S. has tested Ghost Robotics’ quadrupeds with mounted firearms, sparking controversy. Meanwhile, South Korea and Russia are exploring quadruped drones for reconnaissance in hazardous terrain.

The market itself is booming: quadruped robots are projected to grow rapidly as their applications expand from logistics and inspection to defense. A recent MarketsandMarkets report projects the global quadruped robot market to reach over $3 billion by 2030, with defense and security among the key drivers.

Symbolism, Culture, and Control

Why not just call them all dogs? Because symbolism matters. Dogs are companions. Wolves are predators. By invoking wolves, militaries tap into deep-seated cultural associations of danger, loyalty to the pack, and raw survival.

This framing could also help ease public discomfort. Seeing a “robot dog” patrolling a battlefield conjures a strange, almost cartoonish image. Calling it a “robot wolf” feels more aligned with its intended purpose: not to befriend humans, but to hunt their enemies.

What Comes Next?

The canine debate raises broader questions about the language we use to describe machines. Are we headed for a taxonomy of animal metaphors—robot panthers for stealth missions, robot lions for heavy combat, robot hyenas for swarm tactics? Each term shapes not only perception but policy.

For now, the wolf/dog divide is an odd but telling reminder: how we name robots may prove just as influential as how we build them. Semantics may separate robots that stock shelves from those that fight wars, but behind the language lies a single reality—machines once designed for companionship and convenience are now being drafted into the art of war.

Robot News Of The Week

RealSense deepens NVIDIA ties with new D555 depth camera

RealSense, newly independent after spinning out from Intel, is strengthening its partnership with NVIDIA to drive the next wave of robotics. At the center of this collaboration is the new RealSense D555 depth camera, which debuts the company’s v5 Vision Processor with Power over Ethernet, a global shutter, an integrated IMU, ROS 2 support, and direct streaming into NVIDIA’s Holoscan platform for ultra-low-latency sensor fusion.

On the compute side, the integration leverages NVIDIA’s Jetson Thor, built on the Blackwell GPU architecture, which delivers 2070 teraflops of AI performance within a 130W power envelope. This represents a massive jump over Jetson Orin, enabling large-scale generative AI models and advanced perception pipelines to run at the edge. Together, the D555 and Jetson Thor aim to provide robotics developers with faster prototyping through Isaac Sim, optimized pipelines for real-world applications, and real-time sensor fusion that enhances safety when robots work alongside people.

Demand for the D555 has been immediate, with the first production run quickly selling out. Engineers testing the system have noted near-zero latency and frame rates of up to 90 FPS, which is faster than human vision, allowing robots to react more quickly and safely in dynamic environments. RealSense sees this collaboration as a pivotal step in scaling physical AI across autonomous mobile robots, humanoids, and logistics systems. As CEO Nadav Orbach said, the initiative cements RealSense’s role as the perception platform of choice for next-generation robotics.

Robotics Startup Nears $600M Valuation Amid $4B Investment Boom

A little-known startup developing advanced robotic arms is preparing for a significant funding round that could value it at $600 million, according to The Information. The company specializes in modular, AI-integrated arms for manufacturing and logistics, designed to adapt quickly to factory needs. Initial discussions suggest that backing may come from prominent investors, such as General Catalyst.

This move comes amid a surge in robotics investment, with global funding reaching $4.35 billion in July 2025 alone, according to The Robot Report. The potential deal would mark a sharp jump from the startup’s earlier rounds and reflect investor appetite for automation solutions that address labor shortages and supply chain challenges.

Industry observers note the valuation mirrors trends in AI startups commanding premium prices, such as Tome’s recent $600 million discussions. The startup’s edge lies in delivering cost-effective, AI-enhanced arms that could disrupt incumbents like ABB and Zebra Technologies, and even position it within the broader AI hardware ecosystem dominated by Nvidia.

If successful, the funding could accelerate expansion into new markets like healthcare robotics and autonomous vehicles, signaling a maturation point for robotic arms technology at a time when automation is increasingly central to global industry.

Orchard Robotics, an agtech startup using AI to solve farming’s data problem, raises $22M

Orchard Robotics, an agtech startup founded in 2022 by Charlie Wu, has raised $22 million in Series A funding led by Quiet Capital and Shine Capital, with additional support from General Catalyst and other investors. The company, based in San Francisco with teams in Washington and California, has now raised over $25 million in total.

Orchard Robotics mounts cameras on farm equipment to capture images of crops, which are then analyzed by its AI system to track growth, yield, and health. Focused initially on apple and grape farms, the technology now supports blueberries, cherries, almonds, pistachios, citrus, and strawberries.

Wu, who left Cornell to launch the company, says the mission is to solve farming’s “data bottleneck” by delivering precise, actionable insights that boost profitability and sustainability. Investors also include Formula One driver Nico Rosberg and Yext founder Howard Lerman.

Robot Research In The News

A robot learns to handle bulky objects like humans do after just one lesson

Robots excel at tasks like planetary exploration and surgery, but still struggle with basic human dexterity. A team at the Toyota Research Institute has made progress by teaching a humanoid robot, Punyo, to use its whole body—rather than just its hands—to handle large, unwieldy objects.

In experiments, Punyo lifted a water jug onto its shoulder and carried a large box, relying on soft, pressure-sensing skin and joint sensors for feedback. The robot’s success came from combining passive compliance (a soft body) with active compliance (flexible joints), which boosted performance by more than 200% compared to a rigid version.

Using example-guided reinforcement learning, researchers trained Punyo with only a single demonstration in simulation, after which it refined the skill on its own. This approach suggests robots could soon learn to manage tasks like moving furniture, carrying heavy packages, or assisting with care—making them far more useful in everyday settings.

RoboBallet: Planning for multirobot reaching with graph neural networks and reinforcement learning

Modern factories often use many robots working together in busy spaces, but planning their movements without collisions is very hard. Right now, humans usually design these paths by hand, which takes a lot of time and effort.

To address this, researchers developed a system that utilizes reinforcement learning and graph neural networks to automate task planning and movement execution. They tested it with eight robots doing 40 reaching tasks in an obstacle-filled workspace, where any robot could handle any task in any order.

The system learns in simulation with various robot setups and obstacle layouts, then applies that knowledge to new situations without requiring additional training. It can quickly assign tasks, schedule work, and plan safe paths for all robots at once. Its speed and flexibility could help factories optimize layouts, recover from faults, and adapt to changing tasks in real time.

Robot Workforce Story Of The Week

Micron grant brings statewide teachers to SUNY Oswego for robotics training

Just before SUNY Oswego’s fall semester, 10 middle and high school teachers from across New York gathered on campus for a three-day robotics training funded by Micron Technology. Using VEX IQ robotics kits, the teachers built and tested robots in hands-on competitions, gaining skills they can bring back to their classrooms.

The program is part of the launch of the SUNY Oswego Regional Center for STEM Excellence, a partnership with Micron designed to prepare students for careers in technology and advanced manufacturing. Demand for the training was immediate, with the first class filling in less than three hours.

Teachers like Leah Wooster and Andrya Heller said the experience gave them new tools for teaching problem-solving and real-world skills, while also making robotics more accessible for younger students. Alumni instructors and mentors tailored lessons to the group, sparking ideas for new classroom programs and competitions.

Micron, which is investing $100 billion in manufacturing in central New York, sees education as essential to building the region’s future workforce. The company’s partnership with SUNY Oswego includes robotics training, expanded math support, and STEM programming aligned with industry needs.

The initiative will continue in spring, when teachers return with their students for a campus robotics competition—combining learning, teamwork, and fun while inspiring the next generation of engineers.

Robot Video Of The Week

Humanoid robots have improved significantly in their ability to walk and move their entire bodies, but they still struggle with fast, hands-on tasks in dynamic environments. A good example is table tennis. Since the ball can travel faster than 5 meters per second, players must see, predict, and react in under a second, combining quick thinking with precise movements.

To tackle this challenge, researchers built a special system for humanoid robots. It uses a planner to figure out the ball’s path and decide where, when, and how fast the robot should hit it. At the same time, a controller runs the robot’s arms and legs so it can swing the paddle like a human and stay balanced during rallies. To make the movements look natural, the robot was also trained using real human motion as examples.

Tests showed strong results. On a general-purpose humanoid robot, the system managed up to 106 rallies in a row against a human and could even keep up rallies with another humanoid robot. This shows that humanoid robots can now play real table tennis with reaction speeds close to human players, a major step toward more agile and interactive robot behavior.

Upcoming Robot Events

Sept. 15-17 ROSCon UK (Edinburgh)

Sept. 23 Humanoid Robot Forum (Seattle, WA)

Sept. 27-30 IEEE Conference on Robot Learning (Seoul, KR)

Sept. 30-Oct. 2 IEEE International Conference on Humanoid Robots (Seoul, KR)

Oct. 6-10 Intl. Conference on Advanced Manufacturing (Las Vegas, NV)

Oct. 15-16 RoboBusiness (Santa Clara, CA)

Oct. 19-25 IEEE IROS (Hangzhou, China)

Oct. 27-29 ROSCon (Singapore)

Oct. 29-31 Intl. Symposium on Safety, Security, and Rescue Robotics (Galway, Ireland)

Nov. 3-5 Intl. Robot Safety Conference (Houston, TX)

Dec. 1-4 Intl. Conference on Space Robotics (Sendai, Japan)

Dec. 11-12 Humanoid Summit (Silicon Valley TBA)

Mar. 16-19 Intl. Conference on Human-Robot Interaction (Edinburgh, Scotland)

Mar. 29-Apr. 1 IEEE Haptics Symposium (Reno, NV)