Robotics for the Rest of Us: Why Main Street Can’t Wait

The automation revolution is booming—but if it doesn’t work for small businesses, it doesn’t work at all.

Aaron’s Thoughts On The Week

“If we don’t get equality in tech, we risk building a future that reinforces the past.” - Melinda Gates

Automation is having a moment. The robotics revolution is in full swing, from humanoids strutting around nearly every robot expo you attend these day to high-speed robotic arms packaging millions of consumer goods to get you your e-commerce shipment. But while the headlines buzz with billion-dollar rounds and factory floors humming with autonomous fleets, there’s a quieter question that still needs answering: when will Main Street see the benefits?

In short, when will robotics stop being the domain of tech giants, mega-manufacturers, and science-fiction prototypes, and start truly helping small manufacturers, rural hospitals, and your neighborhood construction crews?

The truth is, for many of these everyday businesses, automation still feels more like a promise than a tool they can actually use. The benefits seem just out of reach—locked behind high costs, complex interfaces, and systems designed for scale, not flexibility. Many small business owners are too busy keeping their heads above water to wade into the technical weeds of robot integration. They need tools that work out of the box, survive in unpredictable environments, and don’t require a robotics engineer on staff to keep them running.

And yet, the need has never been more urgent. Labor shortages, rising costs, and supply chain volatility are squeezing local businesses from all sides. These are precisely the kinds of conditions where robotics should shine—if only the tools were designed for the real-world constraints of Main Street, not just the clean floors of an advanced manufacturing lab.

So what would it take to make robotics not just visible in everyday life, but viable? Let’s see if we can start to answer that.

The Promise That Hasn’t Reached the Ground

The case for robotics is strong. Lower injury rates, higher productivity, improved consistency, and long-term cost savings all make automation an obvious choice for high-volume operations. McKinsey estimates that nearly half of all work activities could be automated using existing technologies, with significant gains in efficiency and safety. Meanwhile, the National Safety Council reports that robotics can significantly reduce workplace injuries, especially in repetitive or high-risk tasks.

But that promise often evaporates when a small business owner asks, “Can I afford this?” or “Will this work in my unpredictable, small-scale environment?”

Take the construction industry. While companies like Built Robotics and the newly funded Cosmic Industries are developing robots that can dig trenches or install solar panels, most small contractors still rely on handheld tools and sweat. The upfront cost of robotics, lack of technical support, and the unpredictability of job sites make deploying automation a tall order. A 2023 Dodge Construction Network report found that small firms remain hesitant to adopt automation due to a lack of scalable, affordable solutions.

Similarly, in manufacturing, cobots (collaborative robots) have made strides, but many are still too expensive or complex for mom-and-pop machine shops. According to the International Federation of Robotics, cobot adoption is growing rapidly in large enterprises, but penetration among small and medium enterprises (SMEs) lags behind due to integration challenges and cost barriers.

And in healthcare, while high-end hospitals experiment with autonomous delivery carts and surgical robots, rural clinics often lack even basic automation tools like automated medication dispensing or digital patient intake systems. A 2022 RAND Corporation study noted that rural healthcare facilities face unique challenges in adopting health tech, including robotics, due to infrastructure gaps and limited budgets.

What Real Accessibility Looks Like

Making robotics accessible doesn’t just mean making it cheaper. It means designing for environments where space is tight, downtime is not an option, and staff aren’t trained in robotics.

Accessible robots should be:

Modular: Easy to reconfigure for different tasks.

User-friendly: Operable by non-engineers, with simple interfaces.

Serviceable: Maintainable without a Ph.D. or a service contract that costs more than the robot.

Affordable: Total cost of ownership must make sense for a business with a few employees, not hundreds.

Startups like Flexxbotics are making inroads by offering robotic systems that are not only cost-effective but designed to plug directly into existing small-batch manufacturing setups. Flexxbotics' platform provides real-time machine integration with shop floor equipment, making automation attainable for smaller firms that run CNCs and mills. Their solutions are built to deliver ROI in months, not years, with software tools that make onboarding intuitive for non-specialists.

In agriculture, companies like Naïo Technologies and AgXeed are developing small-scale autonomous tractors and weeding robots designed for small and mid-sized farms. These aren't flashy humanoids—they're workhorses designed to run in the mud, day after day. Naïo’s robots, like the Dino and Oz, are already working on vineyards and vegetable farms across Europe and the U.S., handling tasks like weeding and row navigation with minimal oversight.

These examples show that automation can be both powerful and practical—when it’s designed for the realities of smaller operations. The challenge now is scaling that mindset, not just the machines.

Why It Matters Now

This conversation isn't just about equity—it's about economic survival. The skilled labor shortage is hitting small businesses the hardest. According to the National Federation of Independent Business, over 40% of small business owners report having job openings they can’t fill. Construction firms, rural hospitals, and small manufacturers are operating with minimal staff, struggling to meet demand while avoiding burnout.

Without access to automation, these businesses risk collapse—or consolidation. When labor gaps can’t be filled, and margins remain tight, the threat of being swallowed by larger, more tech-savvy players becomes all too real. A Harvard Business Review article outlined how technology gaps are a key factor in widening economic inequality between big and small firms.

Moreover, the demand for robotics is no longer confined to tech-forward sectors. A Brookings Institution report emphasized that robotics could significantly aid in rebuilding aging infrastructure, accelerating renewable energy projects, and expanding healthcare delivery—especially in rural and underserved areas.

Take clean energy: Solar and wind energy projects, especially those linked to powering data centers and grid upgrades, are being stalled due to a lack of skilled installers. Firms like Cosmic Industries are creating automation tools to close that labor gap, but widespread success depends on scale and affordability. In healthcare, mobile robots are already helping with basic logistics tasks—yet their reach rarely extends beyond large urban hospital systems.

As the World Economic Forum notes, robotic tools can reduce administrative workloads, enhance care delivery, and help rural systems do more with less—but only if the technology is made available to all.

The takeaway? Expanding access to robotics isn’t just a “nice to have.” It’s a foundational part of ensuring local economies can keep pace with national challenges. And that means designing robots—and the policies that support them—for everyone, not just the top 10%.

Who’s Building for Main Street?

The good news is that a growing number of companies, researchers, and nonprofits are trying to close the gap.

The ARM Institute is working with educators and manufacturers to build workforce pipelines and develop plug-and-play robotic tools that are better suited for small business needs.

Open source robotics projects, like those supported by ROS (Robot Operating System), are helping reduce software costs and lower the barrier to entry for custom automation.

Organizations like MassRobotics and MForesight are helping small users, not just VC firms, get practical robotics innovations and talent into their hands.

The Association for Advancing Automation (A3) is also driving awareness and education through its training programs, standards advocacy, and regional events to demystify robotics for small and mid-sized enterprises. By connecting solution providers with Main Street businesses, A3 plays a vital role in building trust and bridging the knowledge gap.

The Robotics and Intelligent Machines (RIM) Program at Georgia Tech bridges academic research and field deployment by focusing on low-cost robotic platforms specifically for underserved sectors like eldercare, agriculture, and disaster response.

Together, these efforts are planting the seeds of a more inclusive robotics future—one where small businesses can innovate without being left behind.

Looking Ahead: What Needs to Change

To bring robotics to Main Street, we need:

Better distribution channels: Small businesses don't go to trade shows. They need robots sold through local suppliers or integrators they already trust. These partners can offer personalized advice, installation, and ongoing service—just like they already do with other equipment.

Simplified financing: Monthly service models and tax incentives can make adoption less risky. Accessible leasing or Robot-as-a-Service (RaaS) plans lower the upfront cost barrier and align better with small business cash flow.

Training and support: Not just on how to use robots, but how to adapt workflows to take advantage of them. Businesses need ongoing guidance to redesign processes, retrain workers, and measure success over time.

A shift in design philosophy: From high-tech complexity to rugged simplicity. Robots for Main Street should be easy to install, maintain, and repair—built to handle dust, drops, and everyday wear without a dedicated technician on site.

We also need better storytelling. Too many robotics narratives focus on science-fiction futures or billion-dollar factories. The public needs to hear more about the welding shop that doubled output with a $20,000 cobot, or the rural clinic using a telepresence robot to reduce ER visits.

It’s time to showcase the unsung stories of automation—the stories of bakery owners who use a robot to mix dough through the night, or of a small-town machine shop that kept its doors open because a cobot took over repetitive deburring work. These narratives aren’t just heartwarming—they’re proof that robotics works when it's grounded in the real needs of real people. Telling these stories builds confidence, dispels myths, and shows that you don’t need a PhD, a cleanroom, or a VC check to participate in the future of automation.

The Bottom Line

The robotics revolution doesn’t reach its full potential until it reaches everyone. Main Street matters—not just because it’s where much of the economy lives, but because it’s where robotics can have the biggest, most immediate impact on real people’s lives.

So the next time we cheer a humanoid robot climbing stairs, let’s also ask: who’s helping the diner down the street automate its dishroom? Who’s building for the roofer, the rural nurse, or the farmhand?

Because that’s when robotics will truly arrive.

Robot News Of The Week

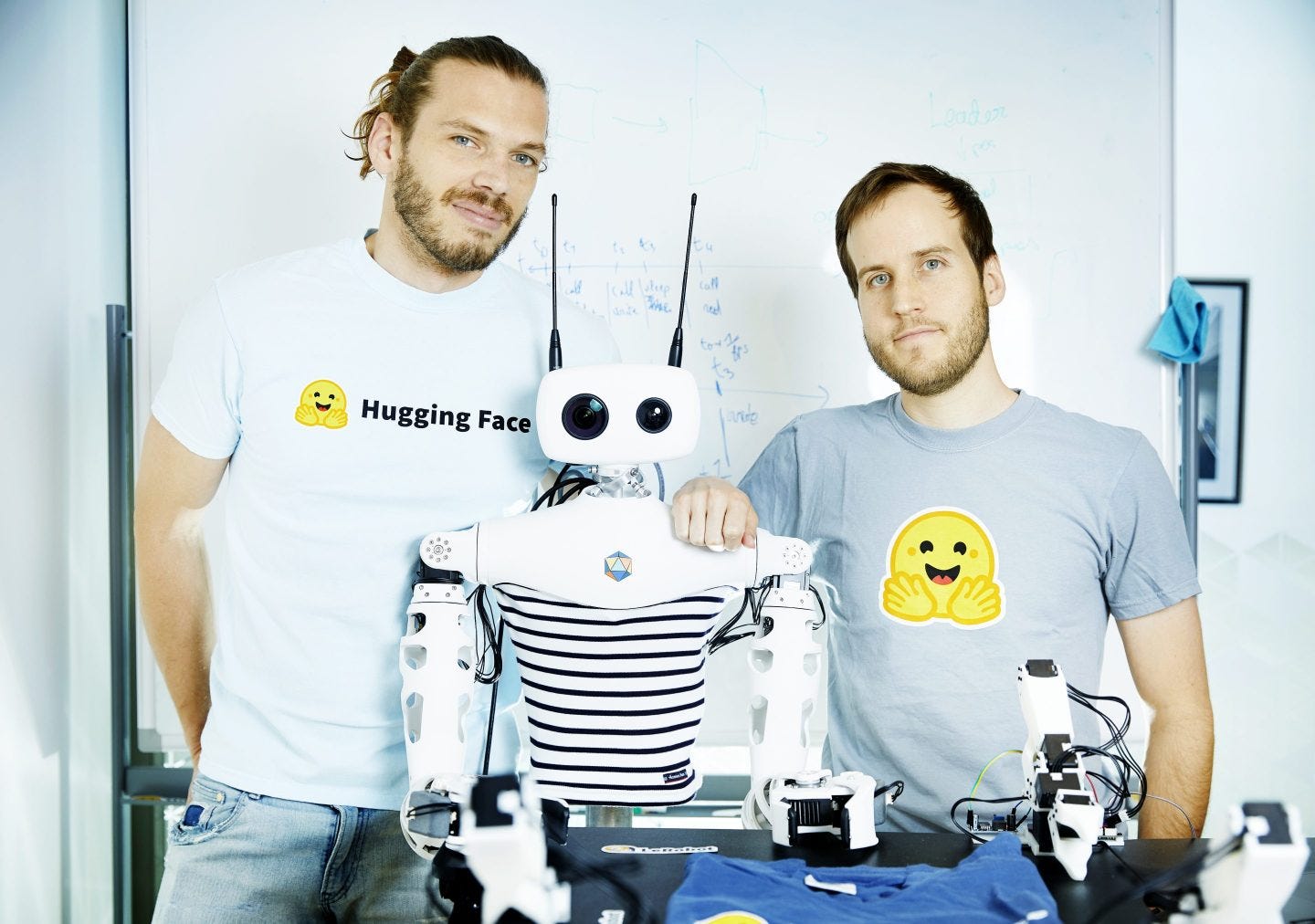

AI company Hugging Face buys humanoid robot company Pollen Robotics

AI leader Hugging Face has acquired French startup Pollen Robotics, known for its open-source humanoid robot Reachy 2, used in research at Cornell and Carnegie Mellon. The 20-person team, including co-founders Matthieu Lapeyre and Pierre Rouanet, will join Hugging Face.

The deal marks Hugging Face’s first move into hardware sales. It previously partnered with Pollen on open-source software and launched its own robotics code library, LeRobot. The company also recently collaborated with The Robot Studio on the $100 SO-100 arm and was chosen by Nvidia as a key AI platform for robotics.

Co-founder Thomas Wolf emphasized the need for open-source AI in robotics for safety and transparency, citing recent vulnerabilities found in closed systems like Unitree’s robot dog. Hugging Face plans to reduce Reachy 2’s $70K price and eventually open-source the robot’s hardware for DIY manufacturing.

“Robotics is the next frontier AI will unlock,” said Wolf.

Xaba raises $6M to build ‘synthetic brains’ for industrial robots

Xaba Inc. is revolutionizing industrial automation with AI-powered robotics that require zero coding. The Toronto-based startup secured a $6M seed extension to expand its xCognition platform, which allows robots to self-program and adapt in real time. By replacing manual programming with generative AI, Xaba claims to cut deployment costs by up to 80% and reduce waste and rework. Its tech supports welding, drilling, machining, and 3D printing across industries like aerospace and automotive. Backed by Hitachi Ventures, Xaba’s goal is to finally make smart factories scalable by integrating AI with legacy and modern manufacturing systems.

ABB to spin off world's second biggest robotics business

ABB announced it will spin off its robotics division—the world’s second-largest industrial robot maker after Japan’s FANUC—as a separate, publicly traded company by Q2 2026. The move follows a slowdown in robot sales, especially in the auto sector, despite $2.3B in 2024 revenue. ABB sees limited synergies with its core business and believes robotics will thrive independently amid global labor shortages and rising costs. CEO Morten Wierod and major shareholder Investor AB support the plan. The robotics unit may list in Sweden or Switzerland, with an estimated value of $2.7–$3.3B. ABB shares rose 3.5% on the news.

Robot Research In The News

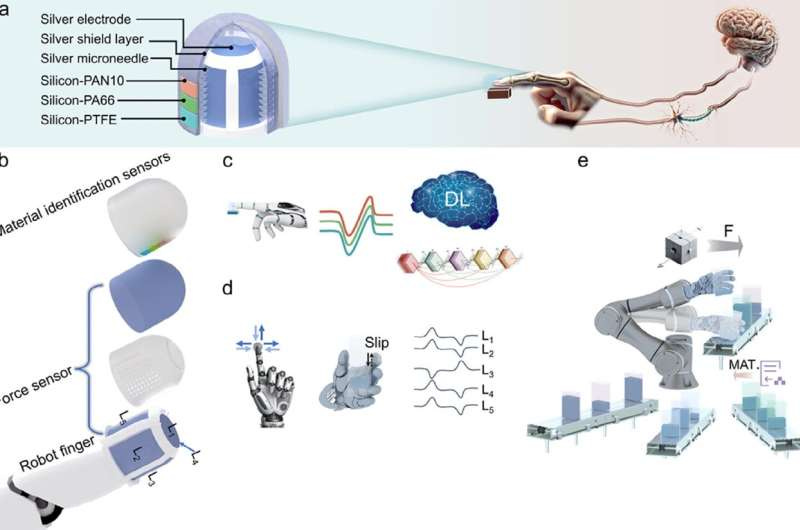

Researchers at the Chinese Academy of Sciences have developed a human fingertip-inspired multimodal tactile sensor that detects both the direction and magnitude of forces and identifies 12 common materials with 98.33% accuracy. Using a triboelectric-based design, the sensor features separate layers for force detection and material recognition. When integrated into a robotic hand, it enables real-time sorting and touch-based interaction, offering promising applications for intelligent robotics, prosthetics, and virtual reality. Future improvements may expand its material range and tactile sensitivity.

Robot Workforce Story Of The Week

Creating lifelong learners through robotics and equity

At the Future of Education Technology Conference (FETC), longtime STEM educator Lori Colangelo shared how integrating robotics in the classroom prepares students for an evolving tech-driven future. A VEX Robotics collaborator, she highlighted how robotics supports not just STEM, but all subjects, building critical life skills. “Engineering makes life better—it fits any class,” she said. Colangelo also emphasized equity in education, urging teachers to ensure every student has a chance to contribute. “We never know who might cure cancer or save the planet,” she noted, encouraging educators to plan lessons that reach and uplift every learner.

Robot Video Of The Week

RoboCake is an edible robotic wedding cake created by EPFL, IIT, and pastry chefs from EHL. Unveiled at Expo 2025 Osaka, it features gummy robotic bears powered by edible chocolate batteries. Part of the RoboFood project, the cake showcases the potential of edible robots in areas like emergency nutrition, healthcare, and sustainability. The bears move using air-powered systems, while the chocolate batteries safely light up candles. By blending robotics with gourmet pastry, the project highlights how tech and food can create interactive, waste-reducing culinary experiences—and maybe even transform how we deliver food and medicine in the future.

Upcoming Robot Events

Apr. 23-26 RoboSoft (Lausanne, Switzerland)

Apr. 30-May 1 Robotics Summit (Boston, MA)

May 12-15 Automate (Detroit, MI)

May 17-23 ICRA 2025 (Atlanta, GA)

May 18-21 Intl. Electric Machines and Drives Conference (Houston, TX)

May 20-21 Robotics & Automation Conference (Tel Aviv)

May 29-30 Humanoid Summit - London

June 9-13 London Tech Week

June 17-18 MTC Robotics & Automation (Coventry, UK)

June 30-July 2 International Conference on Ubiquitous Robots (College Station, TX)

Aug. 17-21 Intl. Conference on Automation Science & Engineering (Anaheim, CA)

Sept. 15-17 ROSCon UK (Edinburgh)

Sept. 27-30 IEEE Conference on Robot Learning (Seoul, KR)

Sept. 30-Oct. 2 IEEE International Conference on Humanoid Robots (Seoul, KR)

Oct. 6-10 Intl. Conference on Advanced Manufacturing (Las Vegas, NV)

Oct. 15-16 RoboBusiness (Santa Clara, CA)

Oct. 19-25 IEEE IROS (Hangzhou, China)

Oct. 27-29 ROSCon (Singapore)

Nov. 3-5 Intl. Robot Safety Conference (Houston, TX)

Dec. 11-12 Humanoid Summit (Silicon Valley TBA)