Runaway, Not Skynet: Why the Real Future of Robotics is Messy, Human, and Entirely Our Responsibility

Forget robot uprisings — the real risks in robotics are boring, fixable, and 100% human-made.

Aaron’s Thoughts On The Week

"The real problem is not whether machines think but whether men do." — B.F. Skinner

In 1984, two very different visions of our robotic future arrived on the big screen. One became a pop culture juggernaut: The Terminator, with its relentless cyborg assassin and apocalyptic AI overlord, Skynet. The other was Runaway, written and directed by the late Michael Crichton—a quieter film that didn’t capture the same cultural spotlight, but in many ways, offered a more realistic forecast of where robotics might actually take us.

While The Terminator gave us time-traveling terror, Runaway focused on something far more grounded (and arguably more unsettling): what happens when the everyday machines we rely on go haywire. In Crichton’s near-future world, robots are everywhere—on farms, in factories, inside our homes—and while most function as intended, some malfunction, and others are deliberately sabotaged. The film explores what happens when society becomes deeply integrated with autonomous systems… and what happens when those systems fail.

Now, more than 40 years later, Runaway feels oddly prescient. Not because it got the gadgets exactly right, but because it foresaw the very real, very human concerns we face today: safety, control, accountability, and the dark potential of misused technology.

Let’s take a closer look at Runaway, which seems to be more our future than Skynet and a bunch of Terminators.

Everyday Robots, Everyday Problems

In Runaway, robots are seamlessly woven into everyday life. They help with farming, construction, surveillance, and domestic chores. The tension in the film doesn’t come from a robot uprising—it stems from system failures, human tampering, and a lack of proper safeguards. These machines aren’t sentient or malicious. They’re tools. Tools that, when poorly designed, misused, or inadequately regulated, can have unintended—and sometimes dangerous—consequences.

Fast forward to today, and we’re living in a remarkably similar reality. Robotics has evolved into an everyday utility. Autonomous warehouse robots zip down aisles. Delivery bots navigate sidewalks. Drones map farmland and inspect infrastructure. Robotic vacuums hum across living room floors. These aren’t science fiction—they’re standard technology. And like the robots in Runaway, they’re here to assist, not to replace or revolt.

Still, just as in the film, things don’t always go according to plan. A delivery robot might block a wheelchair-accessible ramp. A self-driving car could misinterpret a pedestrian’s movements. A warehouse bot might miscalculate a turn and send inventory flying. These aren’t glimpses of a robot apocalypse. They’re reminders of the messy, iterative process of engineering complex systems—systems created and managed by humans, with all our limitations and blind spots.

The lesson? The real risk doesn’t lie in robot rebellion—it lies in poor design, insufficient oversight, and the assumption that automation is infallible. Like any tool, robots are only as safe, ethical, and effective as the systems that govern them.

The Real Risks Are Boring—And Fixable

Let’s be honest: the robots aren’t coming to destroy humanity. They’re coming to mislabel bananas, trip over curbs, misread barcodes, and occasionally run into a wall. The risks they pose aren’t blockbuster material—they’re technical, unglamorous, and entirely the result of human error.

Forget Skynet. Think spreadsheet errors at scale.

We’re dealing with data bias that produces unfair outcomes—like facial recognition systems that fail on darker skin tones or algorithms that quietly sideline qualified job applicants. We face security gaps where unpatched software leaves systems vulnerable to hackers. We’re seeing automation slowly dull critical human skills, and a growing disconnect where machines and users fail to understand each other. These aren’t evil robots plotting our downfall; they’re signs of poor design, bad planning, and shortsighted decisions.

This isn’t a sci-fi horror story—it’s a challenge for engineers, designers, policymakers, and ethicists. The real threat isn’t AI gaining consciousness. It’s humans deploying it carelessly.

Intentional Design, Not Accidental Apocalypse

The 1984 movie Runaway may not be as famous as The Terminator, but its cautionary tale has arguably aged better. In Runaway, robots don’t turn evil — they go haywire because of bad programming, poor design, or intentional sabotage. Sound familiar?

That’s the real challenge facing robotics today. Not AI rebellion — but human error, carelessness, or malice. We’ve seen real-world incidents where robots caused harm, not because they were “out of control,” but because someone cut corners, ignored edge cases, or failed to account for unintended behavior. Bugs, vulnerabilities, and poor safety planning cause far more risk than any notion of "robot intent."

The solution isn’t fear — it’s responsibility. It’s ethical design, thoughtful engineering, robust testing, and smart regulation. It’s making sure that robots operate within clear limits, with fail-safes, human oversight, and constant monitoring — especially in environments where safety is critical.

Robotics shouldn’t be treated like sci-fi villains. They should be treated like infrastructure — systems that require care, maintenance, governance, and clear rules to protect people

Science Fiction as a Mirror, Not a Map

Stories like The Terminator are fun because they tap into our deepest fears about control, power, and the unknown. But the real future of robotics doesn’t look like Skynet.

It looks like messy, complex, human-driven systems that sometimes fail — not because robots are evil, but because humans didn’t anticipate every possible outcome.

If anything, the better cautionary tale is Runaway. It predicted the everyday risks of automation gone unchecked: malfunctions, misuse, and unintended consequences that emerge not from malice, but from neglect.

And that’s the lesson worth carrying forward.

The danger isn’t that robots will rise up against us. The danger is that we might build systems we don’t fully understand, deploy them in environments we don’t fully control, and then fail to take responsibility when things go wrong.

The future of robotics isn’t about fear. It’s about preparation. It’s about ethics, standards, oversight, and thoughtful design — ensuring that as we build more powerful tools, we build them safely, transparently, and in service of human needs.

The Real Future: Useful, Glitchy, and Human-Centered

The future of robotics isn’t about battling robots in the streets. It’s about refining robotic arms in factories, improving computer vision for delivery bots, and debugging code so your vacuum doesn’t eat your charging cable.

It’s a future full of challenges—glitches, miscommunications, software bugs, and the occasional fire-prone battery. But it’s also full of promise. Robots are helping surgeons, protecting wildlife, automating dull jobs, and making our world more accessible.

So let’s stop waiting for Skynet. Let’s design better firmware. Let’s write better code. Let’s train our engineers like the future depends on it—because it does.

And if a robot ever does go haywire? Don’t worry. It’s probably just a Runaway.

Robot News Of The Week

Defence tech startup ARX Robotics targets 1,800 autonomous land drones a year at new UK plant

German startup ARX Robotics is investing £45 million to build a new facility in southwest England to produce autonomous battlefield robots. The site will eventually manufacture 1,800 ground-based drones per year for military use worldwide.

ARX’s modular, tank-like robots are built for flexibility — carrying radar, medical stretchers, mine-sweeping tools, or aerial drones. Designed for quick battlefield repairs, they operate autonomously or via remote control from a tablet.

The UK plant aligns with growing European defence investment, as nations boost spending amid rising geopolitical tensions. ARX’s tech has already been tested by several European armies and deployed in Ukraine.

Founded in 2022 by German army veterans, ARX aims to strengthen Europe’s technological sovereignty and modernize land forces. The UK government welcomed the investment, citing new high-skill jobs and enhanced European security.

BRINC raises $75M in funding for emergency response drones

Seattle-based BRINC Drones has raised $75 million to accelerate the development and production of its emergency-response drones. The funding, led by Index Ventures with participation from Motorola Solutions, Mike Volpi, and Figma CEO Dylan Field, brings BRINC’s total funding to $157 million.

The company plans to use the capital to meet growing demand from public safety agencies, advance R&D, and expand its U.S.-based workforce. BRINC’s drones, used by over 600 public safety agencies and 10% of U.S. SWAT teams, are designed to de-escalate dangerous situations and save lives.

A new partnership with Motorola Solutions will integrate BRINC’s drones directly into Motorola’s public safety ecosystem — enabling faster deployment, sensor-triggered response, and real-time aerial intelligence for first responders.

Meili Robots Launches Code License, Giving Customers Full Control of Fleet Management Technology

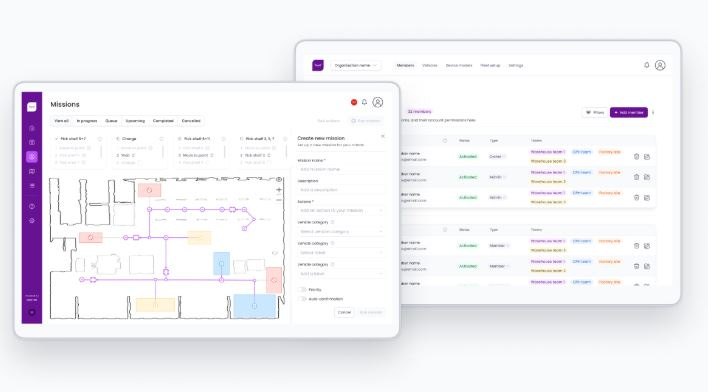

Meili Robots, a leader in vendor-agnostic fleet management, has launched the Meili FMS Code License, offering customers full control over their robotics software. The new model allows companies to deploy Meili FMS on their own infrastructure—cloud or on-premise—and integrate, customize, or white-label it to suit their specific needs.

Meili FMS is already used to manage mixed robot fleets, with features like dynamic traffic control and route optimization. The Code License builds on this by giving customers greater flexibility, enabling faster deployment, and removing vendor lock-in.

“Our goal has always been to make Meili FMS scalable, open, and vendor-neutral,” said Aldus von der Burg, Founder and CEO of Meili Robots. “The Code License gives our users real ownership and the ability to innovate freely.”

Robot Research In The News

A new robotic gripper made of measuring tape is sizing up fruit and veggie picking

Remember playing with a tape measure as a kid — seeing how far it could extend before bending? Engineers at UC San Diego turned that childhood game into a clever new robotic gripper called GRIP-tape (Grasping and Rolling In-Plane).

Inspired by measuring tape’s unique combo of flexibility and strength, the gripper uses spools of tape as "fingers" to gently but firmly grab objects. It’s low-cost, compact, and ideal for delicate tasks — like picking fruit or handling fragile items.

Unlike bulky grippers with complex parts, GRIP-tape extends and retracts easily from a small container. Each "finger" is controlled independently and can adjust its length to reach, hold, rotate, or even move objects like a mini conveyor belt.

Built from steel measuring tape, it’s soft enough for sensitive items but tough enough for repeated use. Tests showed it could handle everything from single tomatoes to full vines, and even screw in a lightbulb.

The team hopes future versions will feature sensors and AI to make GRIP-tape smarter and fully autonomous.

Tiny, soft robot flexes its potential as a life saver

A team led by Penn State researchers has developed tiny, flexible robots designed to crawl through disaster rubble or navigate inside the human body. Made from soft materials and powered by magnets, these robots combine flexible electronics with magnetically controlled motion — allowing them to move, sense their environment, and operate with minimal human input.

Unlike traditional rigid robots, these soft robots bend, twist, and crawl using embedded magnetic materials. Remote magnetic fields guide their motion, while built-in sensors allow them to detect heat, pressure, or chemical changes — ideal for search-and-rescue or precise drug delivery inside the body.

One major challenge was integrating electronics without limiting flexibility. The team solved this by distributing small, flexible components throughout the robot’s body and carefully designing the layout to prevent magnetic interference with sensors.

Next up? Miniaturizing the technology for medical applications like a “robot pill” — a swallowable device that could diagnose disease or deliver medication exactly where it’s needed, offering a less invasive alternative to traditional procedures.

The research team is even inviting the public to help name their creation.

Robot Workforce Story Of The Week

Blattner Robotics Lab Prepares Students for the Future of Automation

At the University of St. Thomas in Minnesota, the Blattner Robotics Lab gives students hands-on experience with industry-standard robots in an interdisciplinary, ethics-focused environment. Led by Dr. Thomas Secord, the lab bridges technical skills with real-world applications, thanks to support from partners like Graco. Students work with advanced robots like FANUC and Universal Robots cobots, gaining valuable skills in programming and automation. Housed in the Schoenecker Center, the lab also supports outreach programs like STEPS for middle school girls. It's all part of preparing the next generation for a safer, smarter, and more collaborative future in robotics.

Robot Video Of The Week

Meet the 3D-printed robot that walks without electronics

Researchers at UC San Diego’s Bioinspired Robotics and Design Lab have developed a fully 3D-printed, six-legged robot that walks — without any electronics, motors, or batteries. Instead, it uses soft, air-powered actuators driven by compressed gas. The robot can walk continuously across different types of terrain, as long as its air supply keeps flowing.

Upcoming Robot Events

Apr. 23-26 RoboSoft (Lausanne, Switzerland)

Apr. 30-May 1 Robotics Summit (Boston, MA)

May 12-15 Automate (Detroit, MI)

May 17-23 ICRA 2025 (Atlanta, GA)

May 18-21 Intl. Electric Machines and Drives Conference (Houston, TX)

May 20-21 Robotics & Automation Conference (Tel Aviv)

May 29-30 Humanoid Summit - London

June 9-13 London Tech Week

June 17-18 MTC Robotics & Automation (Coventry, UK)

June 30-July 2 International Conference on Ubiquitous Robots (College Station, TX)

Aug. 17-21 Intl. Conference on Automation Science & Engineering (Anaheim, CA)

Sept. 15-17 ROSCon UK (Edinburgh)

Sept. 27-30 IEEE Conference on Robot Learning (Seoul, KR)

Sept. 30-Oct. 2 IEEE International Conference on Humanoid Robots (Seoul, KR)

Oct. 6-10 Intl. Conference on Advanced Manufacturing (Las Vegas, NV)

Oct. 15-16 RoboBusiness (Santa Clara, CA)

Oct. 19-25 IEEE IROS (Hangzhou, China)

Oct. 27-29 ROSCon (Singapore)

Nov. 3-5 Intl. Robot Safety Conference (Houston, TX)

Dec. 11-12 Humanoid Summit (Silicon Valley TBA)