The "ChatGPT Moment" for Robotics: Are We Ready for Scale?

Exploring the promise and challenges of scaling robotics—what it will take to overcome hardware limitations and achieve widespread adoption.

Aaron’s Thoughts On The Week

"We are stuck with technology when what we really want is just stuff that works." – Douglas Adams

The tech world has been buzzing with the idea that robotics is on the cusp of its own "ChatGPT moment," where a breakthrough in artificial intelligence and automation could rapidly scale and transform industries overnight. However, while the software side of robotics is advancing at an impressive pace, many experts argue that the hardware required to support such a leap is not yet ready—and may not be for years to come. This raises both exciting possibilities and significant challenges that need to be addressed before robotics can truly scale to meet global demand.

The Promise of a Robotics Breakthrough

Just as generative AI tools like ChatGPT revolutionized content creation, language processing, and automation across various sectors, a similar leap in robotics could redefine industries such as manufacturing, logistics, healthcare, and even household assistance. Potential benefits include:

Increased Productivity

Advanced robotics can significantly boost productivity by performing complex tasks with precision. For instance, Amazon has introduced robots like Robin and Cardinal in its warehouses to handle packages up to 50 pounds, enhancing efficiency and reducing employee injuries. Similarly, Google's development of AI-powered robots aims to assist with everyday tasks, reflecting efforts to integrate robotics into daily operations.

Cost Reduction

Automation through robotics can lower operational costs by minimizing reliance on human labor for repetitive and hazardous tasks. Nvidia's Rev Lebaredian highlights that AI-powered robots are essential due to labor shortages caused by declining population growth, suggesting that robots will help sustain society by performing advanced manufacturing and transportation services.

Enhanced Safety

Deploying robots in hazardous environments can reduce human exposure to risks. For example, autonomous drones and delivery robots are being developed to operate in various settings, minimizing the need for human presence in potentially dangerous situations.

Greater Accessibility

Advanced robots have the potential to democratize access to specialized services. In healthcare, AI-powered robotics are being explored for applications ranging from surgery to rehabilitation, aiming to provide consistent and precise care, especially in underserved areas.

Scalability Across Sectors

Robotics can be applied across diverse industries. In manufacturing, the concept of "Industry 4.0" emphasizes the integration of smart technology and automation to enhance production processes. Additionally, the development of mobile industrial robots introduces new methods for lean manufacturing, allowing for flexible and efficient operations.

Innovation and Job Creation

While automation may replace certain roles, it also creates opportunities for new jobs in robotics maintenance, programming, and oversight. The UK's robotics industry, for instance, has the potential to significantly boost GDP by 2030, offering exciting careers and attracting younger talent by modernizing work environments.

These potential benefits paint an optimistic picture, but the reality is more nuanced. While AI models can be scaled quickly in the cloud, robotics introduces unique challenges related to physical limitations, materials, and infrastructure.

The Hardware Bottleneck

Despite rapid software advancements, robotics hardware development is fraught with challenges that could delay the industry's "ChatGPT moment." Some of the key hurdles include:

Complexity of Mechanical Systems

Developing robots with the necessary precision, dexterity, and durability involves intricate mechanical engineering. This complexity leads to high costs and extended development cycles. Integrating various components—such as sensors, actuators, and control systems—requires a deep understanding and extensive testing to ensure seamless operation.

Supply Chain Challenges

The robotics industry relies on critical components like sensors, actuators, and processors, susceptible to global supply chain disruptions. Events such as semiconductor shortages and geopolitical tensions can delay production and escalate costs. For instance, the U.S. defense sector faces challenges due to dependence on Chinese-supplied components, prompting efforts to diversify supply chains.

Energy Efficiency and Power Limitations

Robots, especially mobile and industrial variants, often require substantial energy to operate. Current battery technologies may not support prolonged autonomous function, making energy efficiency a critical bottleneck. Optimizing energy consumption is essential to enhance the longevity and effectiveness of robotic systems.

Cost of Deployment

Implementing robotic solutions necessitates significant upfront investments in infrastructure, training, and maintenance. The high costs associated with deployment can deter businesses, particularly small and medium-sized enterprises, from adopting robotic technologies. Concerns about return on investment and the complexity of integration further contribute to hesitation.

Regulatory and Safety Concerns

Deploying autonomous robots in public or industrial settings requires adherence to stringent safety regulations. The absence of standardized regulatory frameworks can impede deployment and adoption. It is paramount to ensure that robots operate safely, especially in environments where they interact closely with humans.

Addressing these challenges is crucial for the robotics industry to achieve a transformative breakthrough similar to that seen with generative AI technologies.

Moving Forward: Bridging the Hardware Gap

While the hardware challenges in robotics are substantial, several promising strategies can bridge this gap, bringing the industry closer to its anticipated "ChatGPT moment." Key approaches include modular design, advancements in material science, collaborative human-robot workflows, and standardization through open-source collaboration.

Modular Design Approaches

Adopting modular design in robotics involves constructing systems using interchangeable components or modules. This architecture allows for greater flexibility, scalability, and adaptability, enabling robots to perform various tasks by reassembling modules according to specific needs. Modular robots can be reconfigured to adapt to different functions, enhancing their versatility and reducing maintenance costs. For instance, homogeneous modular robot systems consist of identical modules forming structures suitable for diverse tasks, simplifying scaling by adding more units.

Advancements in Material Science

Progress in material science is pivotal for developing sustainable and efficient robotics. The integration of self-healing, biodegradable, and recyclable materials into robotic components addresses environmental concerns and improves performance. Soft robotics, which utilizes materials like hydrogels and elastomers, emulates the composition of living organisms, leading to novel actuation and sensing mechanisms. These materials contribute to the creation of robots that are not only more adaptable but also environmentally friendly.

Collaborative Human-Robot Workflows

Implementing collaborative human-robot workflows, where robots and humans work side by side, facilitates a gradual transition to full automation. This approach optimizes productivity and safety, allowing robots to assist with repetitive or hazardous tasks while humans handle more complex decision-making processes. Such collaboration enhances operational efficiency and mitigates concerns regarding job displacement, as robots augment rather than replace human labor.

Standardization and Open-Source Collaboration

Encouraging standardization and open-source collaboration in robotics can drive innovation and reduce costs. Standardized components and interoperable software frameworks lower entry barriers for smaller entities and foster a more innovative ecosystem. Open-source initiatives, such as the Robot Operating System (ROS), provide a robust foundation for developers to build and test robotic applications without starting from scratch. This collaborative environment accelerates development and facilitates the integration of new technologies into existing systems.

Conclusion

Achieving the "ChatGPT moment" in robotics requires a multifaceted approach to overcoming existing hardware challenges. By embracing modular design, advancing material science, fostering collaborative workflows, and promoting standardization through open-source platforms, the robotics industry can pave the way for widespread adoption and scalability. These strategies require concerted efforts from manufacturers, researchers, and policymakers to ensure that the infrastructure, regulations, and technologies are in place to support this evolution. The future of robotics is promising, and with strategic initiatives, the industry can realize its full potential, transforming various sectors and enhancing human capabilities.

Robot News Of The Week

MassRobotics opens applications for 2025 Form and Function Robotics Challenge

MassRobotics has launched its third annual Form and Function Robotics Challenge, inviting college teams from around the world to showcase their innovative robotics projects. The competition offers students a platform to present their work to industry leaders and investors, helping them prepare for careers in robotics.

Sereact's €25M Series A raise boosts AI robotics zero-shot visual reasoning

Sereact, a German robotics firm, has raised €25 million in Series A funding. Founded in 2021 in Stuttgart by Ralf Gulde (CEO) and Marc Tuscher (CTO), Sereact develops AI-powered robotics for various US and European industries. Its software endows robots with visual and manipulation skills, allowing them to understand their surroundings and create strategies for diverse physical tasks. Sereact's PickGPT enables robots to follow natural language commands, facilitating deployment in just one day for customers seeking immediate cost savings.

According to Ralf Gulde, the technology allows robots to adapt dynamically to tasks rather than executing pre-programmed instructions, providing unparalleled autonomy. Clients include BMW, Daimler Truck, Bol, and Active Ants. The company leverages real-time data to continuously improve its systems, contrasting the common hardware-first approach in AI robotics. Johan Brenner from Creandum highlights the potential of Sereact's software-first model to revolutionize robotic vision and autonomy, praising European innovation.

Accelerate Program of Pittsburgh Robotics Factory opens applications for its third cohort

The Robotics Factory opened applications for its Accelerate program, focused on advancing robotics startups in the Pittsburgh area. Applications close on Feb. 20, 2025, with selected companies participating from June to December.

Kevin Dowling, managing director of the Robotics Factory, said, "Our first cohorts have spurred impressive startups, and we’re excited to see what new founders can achieve. Unique to the Robotics Factory, entrepreneurs have regular access to a team of professionals with domain and business expertise invested in their success.”

Robot Research In The News

Robotic hand helps pianists overcome “ceiling effect”

Practice is key to mastering motor skills like piano playing. However, expert musicians often hit a "ceiling effect," where their skills plateau after extensive training. A study in Science Robotics suggests robotic exoskeletons could help pianists break through this barrier. Coauthor Shinichi Furuya, a pianist who injured his hand from over practicing, recalled how his teachers guided his hands for advanced pieces. He wondered if a robotic hand could replicate this support. Furuya and his team developed a custom exoskeleton hand that moves fingers independently and flexes joints. Unlike earlier studies focusing on simpler movements, this innovation specifically assists piano playing.

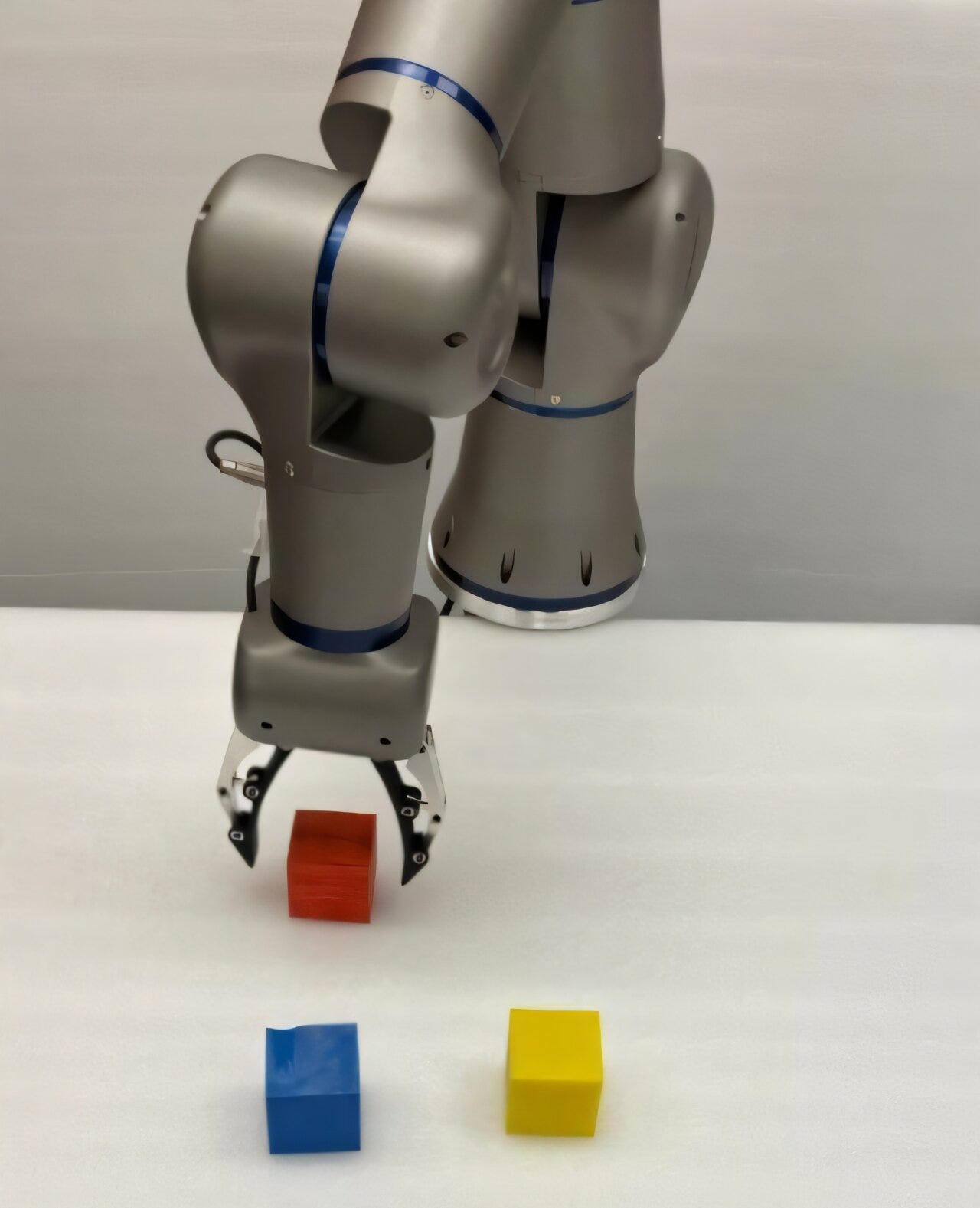

Embodied AI reveals how robots and toddlers learn to understand

Humans excel at generalization, learning concepts like the color red from various objects. A key aspect of this ability is compositionality or reusing components of knowledge. Researchers at the Okinawa Institute of Science and Technology (OIST) have developed a new embodied intelligence model that emulates human learning more closely than traditional AI models. Unlike large language models (LLMs) that rely on massive text data, this model—using a PV-RNN framework—integrates sensory inputs, including vision, proprioception, and language. This allows the AI to learn through interaction, similar to toddlers exploring the world.

Key findings indicate that exposure to the same word in varied contexts enhances learning, similar to how children acquire language by interacting with different objects. The model's structure, inspired by the Free Energy Principle, processes information sequentially, reflecting human cognitive limits like working memory and attention span.

This model boasts transparency and efficiency, needing smaller datasets and less computing power than LLMs. Despite making human-like mistakes, its simpler design allows researchers to see how it processes and retains information, providing insights into AI and human cognition.

Furthermore, the model addresses the Poverty of Stimulus problem by showing that grounding language in real-world behaviors boosts understanding. This embodied approach could lead to safer, ethical AI with better decision-making in critical applications. Ultimately, this research is a promising step toward creating AI that learns and generalizes more like humans, edging closer to truly human-like AI.

Robot Workforce Story Of The Week

UBTECH Unveils Integrated Solutions at BETT 2025

At the BETT 2025 exhibition, UBTECH prominently showcased a diverse array of integrated solutions catering to K-12, vocational, and higher education sectors. The atmosphere was charged with enthusiasm as UBTECH unveiled its most advanced humanoid robots, known as Tien Kung, which marked a significant international debut. Tien Kung stands as the world's first full-size, pure electric drive robot, distinguished by its ability to walk and run in a manner akin to human locomotion.

Moreover, it is noteworthy that Tien Kung has been made open-source, thereby inviting enhancements and innovations tailored to community requirements. Its groundbreaking functionalities are already effecting substantial changes within universities and research institutions, facilitating exciting experiments and fostering academic advancements in the fields of artificial intelligence and robotics.

Robot Video Of The Week

Black Panther V2.0: Robot Dog Sprints Faster Than Elite Athletes

A Hangzhou-based team claims their Black Panther V2.0 robot dog can now sprint at an impressive 10.4 meters per second (23 mph or 37 km/h), completing a 100-meter dash in under 10 seconds—on par with elite human athletes.

Developed by researchers from Zhejiang University and the startup Mirror Me, the robot underwent major upgrades, including a new shock-absorbing leg system with grippy rubber feet to prevent breakage and handle increased motor power.

Weighing 38 kg (84 lbs), the Panther now takes up to five strides per second and, if the released footage is accurate, it’s incredibly fast.

Upcoming Robot Events

Feb. 12-14 Intl. Conference on Automation, Robotics, and Applications (Zagreb)

Feb. 12-15 KROS (Alpensia, Korea)

Feb. 24-26 Intl. Conference on Mechatronics and Robotics Engineering (Lille, FR)

Mar. 4-6 Intl. Conference on Human-Robot Interaction (Melbourne)

Mar. 17-21 NVIDIA GTC AI Conference (San Josa, CA)

Mar. 21-23 Intl. Conference on Robotics and Intelligent Technology (Macau)

Mar. 25-27 European Robotics Forum (Stuttgart)

Apr. 23-26 RoboSoft (Lausanne, Switzerland)

Apr. 30-May 1 Robotics Summit (Boston, MA)

May 12-15 Automate (Detroit, MI)

May 17-23 ICRA 2025 (Atlanta, GA)

May 18-21 Intl. Electric Machines and Drives Conference (Houston, TX)

May 20-21 Robotics & Automation Conference (Tel Aviv)

June 30-July 2 International Conference on Ubiquitous Robots (College Station, TX)

Aug. 18-22 Intl. Conference on Automation Science & Engineering (Anaheim, CA)

Oct. 19-25 IEEE IROS (Hangzhou, China)

"...a similar leap in robotics could redefine industries such as manufacturing, logistics, healthcare, and even household assistance."

That statement is truthful, but stated goals are unreachable with programming.

Robots should be subjective instead of programmable to make them capable of being universal problem-solving tools.

artificiallabor@artificiallabor.co

Michael