The Expanding Role of Standards in Robotics Across Diverse Industries

ASTM launches a new subcommittee to focus on application-level robotics standards across numerous industries

Aaron’s Thoughts On The Week

“Victory comes from finding opportunities in problems.” - Sun Tzu

As robots increasingly move from traditional settings like factories and warehouses to more varied environments such as agricultural fields, construction sites, and solar farms, the need for updated and specialized standards becomes more pressing. Recognizing this, our team at ASTM International has announced the formation of a new subcommittee dedicated to robotics applications. This initiative aims to create a collaborative platform where industry representatives can develop standards tailored to their sectors.

The New Subcommittee's Focus

The newly approved Robotics Applications Subcommittee, part of ASTM's F45 Robotics, Automation, and Autonomous Systems Committee, will address the unique needs of various industries, including oil and gas, agriculture, construction, solar, and nuclear. According to Adam Norton, chair of the F45 committee and associate director of the New England Robotics Validation and Experimentation (NERVE) Center at the University of Massachusetts, Lowell, the subcommittee will allow ASTM members to create standards that are specific to these applications.

“The portfolio of F45 standards to date has been intentionally developed to be general so they can be easily adapted to particular applications,” said Norton. This approach ensures flexibility, enabling standards to be fine-tuned to meet the diverse requirements of different industries.

Building on Existing Standards

The new subcommittee will leverage existing F45 standards to create new specifications, guides, and test methods tailored to specific applications of robotics, automation, and autonomous systems. ASTM has emphasized the importance of these standards in addressing the distinct needs of various sectors, facilitating safer and more efficient deployment of robotic technologies.

“Several task groups for each application area are in the process of being formed,” Norton explained. “These groups, led by subject-matter experts (SMEs), will not only develop standards within the subcommittee but also provide expertise to other subcommittees.”

The subcommittee plans to initially concentrate on the solar, construction, and agricultural sectors. These industries are seeing rapid growth in adopting robotic technologies, making the development of specific standards critical. For instance, robots are increasingly used in agriculture for tasks such as planting, harvesting, and monitoring crop health, which requires precise and reliable standards to ensure safety and effectiveness.

Joining Forces with Existing Subcommittees

The Robotics Applications Subcommittee will join several existing subcommittees under ASTM F45, including:

Invitation to Participate

We would like to invite all interested parties to join the new F45.07, the Robotics Applications Subcommittee, to contribute to this crucial effort. By participating, stakeholders can help shape the standards that will guide the future of robotics in their industries, ensuring that these technologies are deployed safely and effectively.

TL;DR

As robotics use continues to expand into new and diverse fields, the development of industry-specific standards is essential. ASTM International's new Robotics Applications Subcommittee represents a significant step forward in this effort, providing a dedicated platform for developing the standards to support the safe and efficient integration of robotics across various sectors. This initiative not only enhances the capabilities of robotic systems but also fosters innovation and growth in industries ranging from agriculture to nuclear energy.

Robot News Of The Week

Meet the AI-powered robot that’s helping build Amazon-backed solar farms

Amazon and AES have introduced a groundbreaking AI-powered robot, Maximo, to accelerate solar farm construction. Maximo reduces installation timelines and costs by up to 50%, facilitating quicker project delivery and creating new job opportunities. Utilizing advanced technology and AI, Maximo ensures precise and efficient solar panel installation, even in challenging conditions. The robot recently debuted at the Oak Ridge Solar Farm and is now aiding construction at the Bellefield project in California.

Furthermore, Amazon and AES are leveraging AI solutions to support renewable energy projects and address climate change, as demonstrated by their initiatives at the Baldy Mesa solar-plus-storage farm.

NVIDIA Accelerates Humanoid Robotics Development

NVIDIA is offering services, models, and computing platforms to accelerate humanoid development. This includes microservices and frameworks for robot simulation and learning, a cloud-native managed service for orchestration, and a teleoperation workflow for training robots using minimal human demonstration data. These offerings aim to reduce deployment times, simplify robot training and simulation workflows, and capture synthetic motion and perception data from minimal human demonstrations.

ASTM proposes standard for solar panel cleaning robots

ASTM International's F45 Robotics, Automation, and Autonomous Systems Committee is creating a standard for assessing robots that clean solar panels, aiming to modernize the industry. Carla Dawson, an ASTM member, emphasized the need for standards to ensure safety, asset protection, and water conservation as the solar panel cleaning industry expands. Dawson believes that implementing these standards will result in a safer, more enduring, and environmentally conscious industry benefiting solar asset managers, manufacturers, and regulatory bodies.

Robot Research In The News

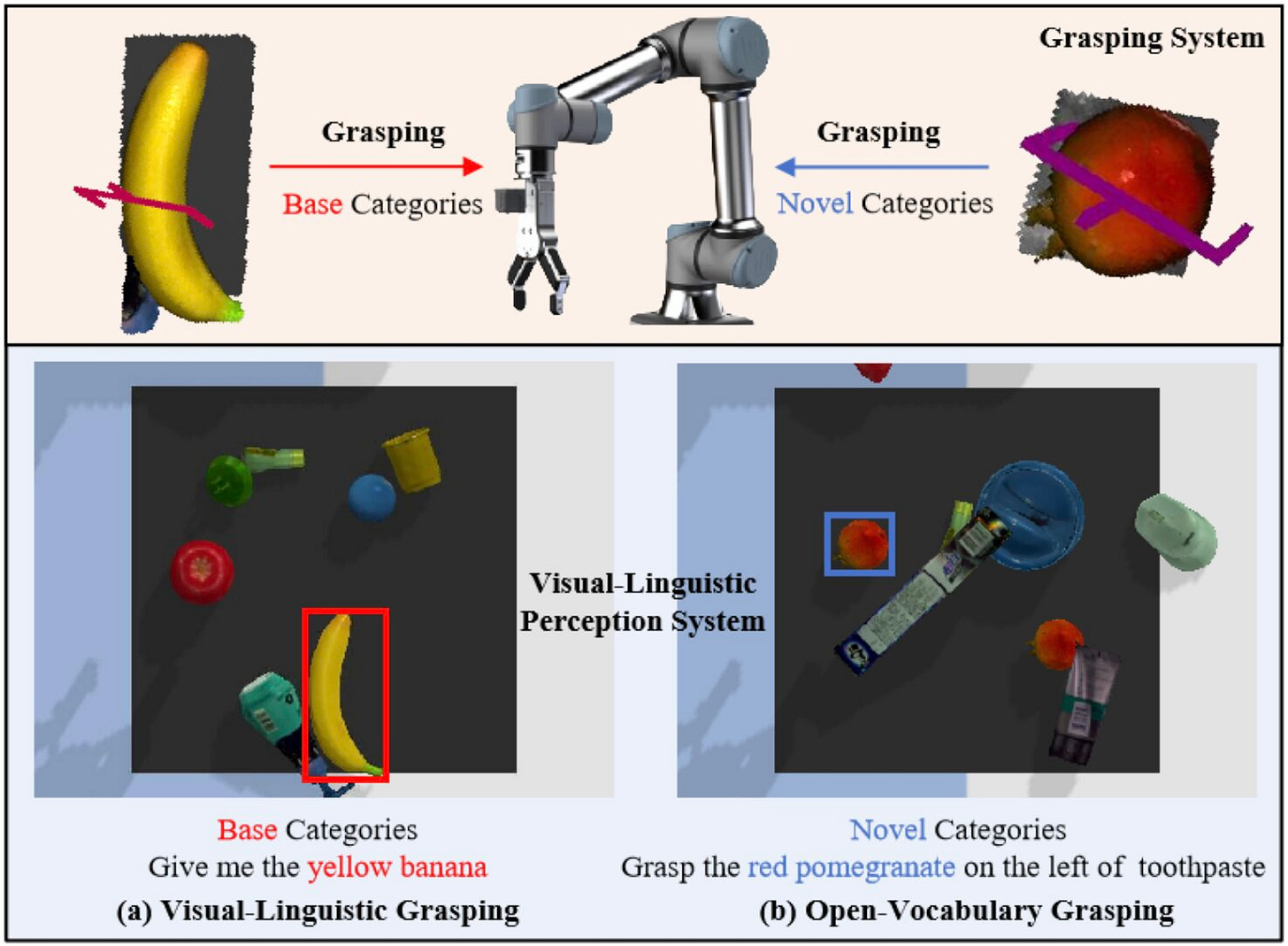

A visual-linguistic framework that enables open-vocabulary object grasping in robots

A team of researchers at Beihang University and University of Liverpool has developed a new approach, OVGNet, to overcome the limitation of robotic systems in grasping novel objects. Their framework, based on a visual-linguistic perception system, achieved promising results in tests with a simulated robot and robotic arm. The researchers also compiled a benchmark dataset called OVGrasping, which is open-source and can be accessed on GitHub. The dataset contains examples of grasping scenarios with objects from different categories, both known and novel. This new approach has the potential to improve robotic grasping in various real-world applications.

U of Idaho, USDA Demo Robotic Weeding System to Improve National Reforestation

The University of Idaho recently demonstrated an advanced robotic device to eradicate weeds at the Coeur d’Alene Nursery. The project partners with the U.S. Department of Agriculture to improve national reforestation efforts. The 3-foot-wide autonomous wheeled robot, designed by U of I computer science students, uses artificial intelligence to scan, identify and precisely locate up to one-half inch of weed growth. The robot uses electricity to eradicate weeds.

The U.S. spends approximately $500,000 annually on weeding at its national tree seedling nurseries. Reducing weeds will improve access to soil nutrients, strengthen seedling quality, reduce nursery costs, and ultimately improve reforestation success. U of I recently earned a grant from the USDA to develop the robot. The U of I team includes computer science graduate students Garrett Wells of Boise and Brent Knopp of Coeur d’Alene; undergraduate student Kevin Wing of Coeur d’Alene; John Shovic, director of U of I’s Center for Intelligent Industrial Robotics; and Mary Everett ’20, ’23 of Lewiston, a postdoctoral researcher at the center.

Robot Workforce Story Of The Week

Motlow State helps with robotics learning

Warren County’s Gifted Students Program visited Motlow-McMinnville to learn robotics at the Automation and Robotics Technology Center. They were introduced to basic robotic controls using small remote-controlled robots provided by Motlow State. The program aims to inspire young minds and showcase the various career opportunities in robotics and mechatronics.

Motlow State’s Mechatronics program prepares students for careers in automation, power production, and manufacturing, offering certifications such as Yaskawa Safety Principles and Intro to Robotics. Larry Flatt, Executive Director of the Automation and Robotics Training Center, encouraged the students to "train today so you can be a champion tomorrow."

Robot Video Of The Week

Neura Robotics, based near Stuttgart, Germany, has unveiled a new video showcasing its general-purpose humanoid robot, 4NE-1. The 1.8-meter-tall, 80 kg robot can perform various domestic tasks, operate machinery, and lift heavy objects. It's equipped with 3D sensors, voice recognition, and can work autonomously or be operated remotely. Neura Robotics has partnered with NVIDIA to accelerate humanoid development, aiming to make humanoid helpers a reality.

Upcoming Robot Events

Aug. 6-9 International Woodworking Fair (Chicago, IL)

Sept. 9-14 IMTS (Chicago, IL)

Oct. 1-3 International Robot Safety Conference (Cincinnati, OH)

Oct. 7 Humanoid Robot Forum (Memphis, TN)

Oct. 8-10 Autonomous Mobile Robots & Logistics Conference (Memphis, TN)

Oct. 14-18 International Conference on Intelligent Robots and Systems (Abu Dhabi)

Oct. 15-17 Fabtech (Orlando, FL)

Oct. 16-17 RoboBusiness (Santa Clara, CA)

Oct. 21-23 ROSCon (Odense, Denmark)

Oct. 28-Nov. 1 ASTM Intl. Conference on Advanced Manufacturing (Atlanta, GA)

Nov. 22-24 Humanoids 2024 (Nancy, France)