The Rise of Mobile Manipulators

Humanoids are getting all of the attention, but mobile manipulators are indeed the next big thing in robotics.

Aaron’s Thoughts On The Week

"I Know It When I See It." - Justice Potter Stewart

I went on The Manufacturing Hub podcast with Dave Griffith and Vladimir Romanov this week. Our focus was on Robot Standards, but we touched on numerous other topics, including humanoid robots. We have talked a lot about humanoid robots here on Six Degrees of Robotics, but some of the chat with Dave and Vlad made me want to go a bit deeper here.

They Are All Mobile Manipulators

One part of the humanoid story that is overlooked is what are the core elements that make a robot humanoid. For many, the main driver is if it looks human, then the robot is humanoid. That is problematic because how one person defines “looks human” will be different from someone else. So we need to make it even simpler than that.

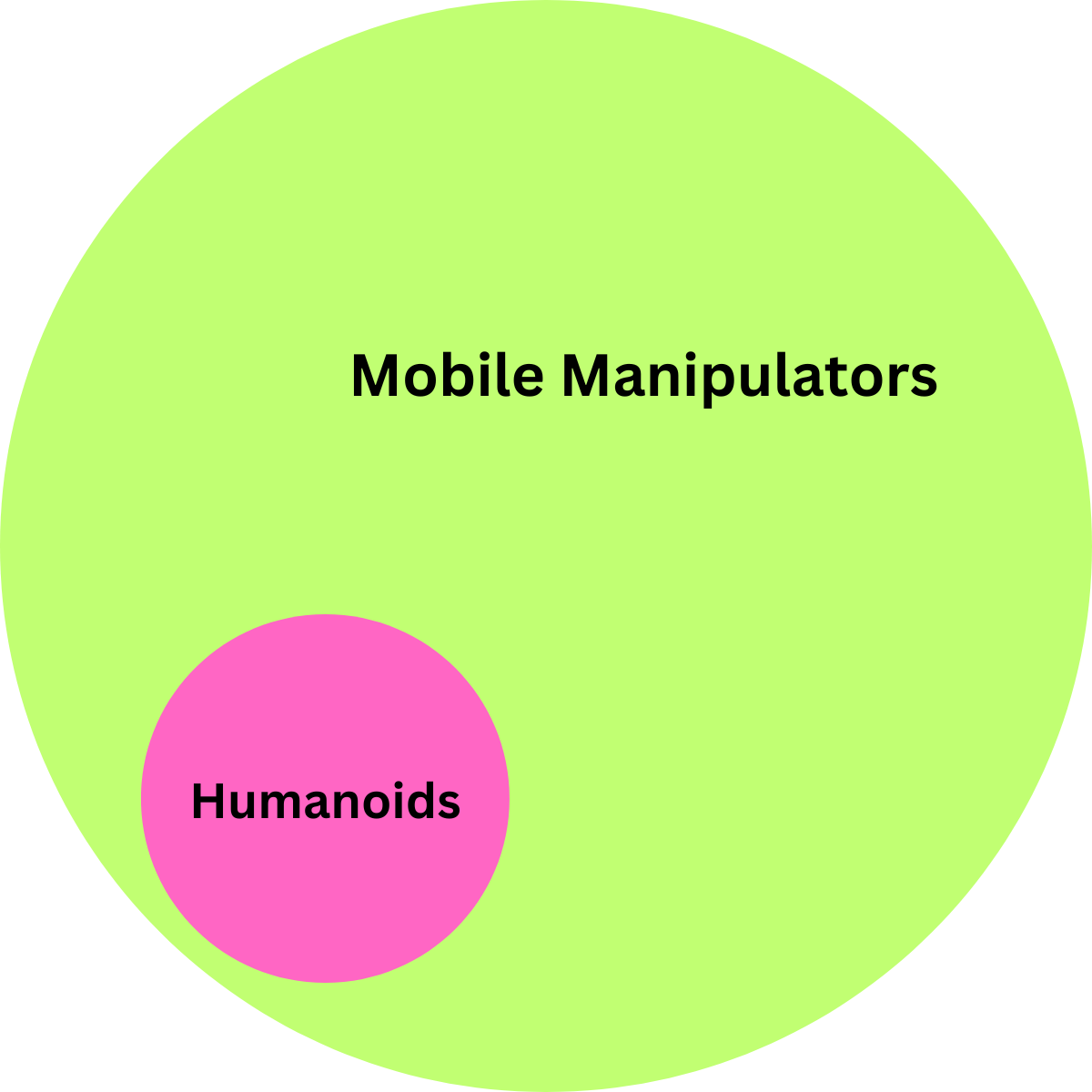

The most essential elements of humanoid robots are manipulation and locomotion. Those are the two human elements that nearly everyone can agree to because that is something almost all “humanoid” robots do. They can manipulate an item and move around in a space. That is also the very definition of a mobile manipulator.

So, we can all agree that all humanoids are mobile manipulators, but that also means that not all mobile manipulators are humanoids.

Mobile Manipulators Are Defined…To A Point

Under ANSI R15.06, Mobile Manipulators are defined as IMR Type C’s. This means we have a robot safety standard for humanoid robots that operate in Industrial settings—again, for Industrial settings only. However, we do not have a safety standard for mobile manipulators and humanoids OUTSIDE of industrial applications yet.

So, for those humanoid companies deploying in Industrial Applications, if you follow R15.06 (where you can), you are following the standards framework as it is currently set. That is good news for everyone.

The issue is that R15.06 does have some gaps when we look at all of the humanoid robot features. This is why all Standards Development Organizations (SDOs) like ASTM, ISO, ANSI, UL, IEEE, and many others, are working to fill those gaps. So there is plenty of work to do.

In the future, though, we must build around the concept of mobile manipulators with humanoids as a subset of that larger group. Mobile Manipulators will be a very fast-growing segment of robotics from now on. The vast majority of those robots are not going to be humanoid.

So What Does This Mean Going Forward?

More humanoid robots will be coming to market, but more mobile manipulators will also. That is why, from a standards perspective, I and the F45 Committee on Robotics and Autonomous Systems Programs will focus on the key elements of manipulation and locomotion.

Subcommittee F45.05 Grasping and Manipulation will publish several mobile manipulation tests and performance standards in 2024. These standards will be agnostic to robot design and focus on how well the robot can move around a work item and then put things on and pull things off of it. These standards will not care if the robot has legs or wheels; they just want to see if the locomotion can get the manipulator to the correct position and even support it during the task.

Subcommittee F45.06 Legged Robots will also be aligned this year to publish test and performance standards in the future. However, their focus is not specifically on humanoids but on any robot that uses legs for its locomotion source.

In other words, while we acknowledge the rise of humanoids, we recognize the growing use of mobile manipulators, which include humanoids and thousands of other types of robots that move and manipulate items. We recommend that the rest of the industry also follow this approach because we need standards not only for humanoids but also for all mobile manipulators.

Robot News Of The Week

Amazon to invest £600m in European robotics and AI over five years

Amazon has been using its innovation lab in Vercelli, Italy, to develop and test new technologies, including over 1,000 new robotics and AI-powered innovations over the last five years. The Amazon Operations Innovation Lab in Europe is one of the most advanced centers for robotic innovation, soon to be open for tours. The lab features item sorters, pallet movers, and automated guide vehicles, which actively support Amazon’s employees across the company’s sites. The introduction of new technologies has enhanced more than 50,000 jobs in fulfillment centers in Europe over the last decade. Robotics and AI-powered innovation improve the price, selection and convenience for Amazon’s customers, allowing the business to deliver to Prime members at the fastest speeds ever globally in 2023.

Northrop Grumman debuts Manta Ray robotic underwater glider

Northrop Grumman's Manta Ray Uncrewed Underwater Vehicle (UUV) is an extra-large submarine glider designed for long-range undersea missions without human assistance. Inspired by the hydrodynamics of manta rays, it combines high-tech autonomous systems and energy-saving propulsion. It carries various payloads for different missions with an emphasis on endurance rather than speed. The exact dimensions of the vehicle are not disclosed.

Collaborative Robotics Raises $100 Million in Series B Funding

Collaborative Robotics has raised $100 million in Series B funding led by General Catalyst and joined by Bison Ventures, Industry Ventures, and Lux Capital. The total funding raised is now over $140 million in less than two years. The new capital will expand the team and advance commercial deployments. Teresa Carlson, an industry leader, has joined the company as an Advisor.

Robot Research In The News

Helping robots make a better first impression

A research team from the University of Waterloo's Social and Intelligent Robotics Research Lab found that people prefer interacting with robots they perceive to have social identities like their own. The study measured the social identities of social robots that humans liked to interact with and focused on perceived sentiments of robotic identities. The study included 95 participants between the ages of 20 and 67 who were asked to evaluate social robots based on the Affect Control Theory (ACT), which emphasizes qualities like goodness, activity, and power.

AI-powered mini soccer star robot falls, gets up to dribble and score

Researchers have used miniature humanoid robots trained through deep reinforcement learning to play soccer matches. The robots demonstrated their mobility and strategic abilities by walking, turning, kicking, and anticipating ball movement. According to the team at Google’s DeepMind, this research may provide a way to teach humanoid robots basic movements and behaviors in dynamic environments. The details of the research were published in the journal Science Robotics.

Robot Workforce Story Of The Week

How Robotics Training Can Address Skills Gaps in Manufacturing

Manufacturers worldwide are struggling with a growing skills gap, particularly in the area of robotics and automation. The retirement of experienced workers, combined with rapid digital transformation, has resulted in a mismatch between worker capabilities and the evolving needs of the industry. This talent shortage is predicted to leave millions of manufacturing positions unfilled and cost billions in lost GDP. Some forward-thinking manufacturers are offering robotics training programs to help close the skills gap and equip their employees with the in-demand skills needed for the future of manufacturing.

Robot Video Of The Week

Researchers at Carnegie Mellon University have created a framework called H2O, which allows a full-sized humanoid robot to be operated by a human using only an RGB camera. This raises the question of whether manual labor will soon be performed remotely. Reinforcement learning comes in handy to achieve whole-body control of human-sized humanoids. It is a machine-learning technique that allows a robot to learn from the feedback of each action it performs and identify the best processing paths to achieve the desired outcome.

Upcoming Robot Events

Apr. 14-17 International Conference on Soft Robotics (San Diego, CA)

May 1-2 The Robotics Summit & Expo (Boston, MA)

May 6-9 Automate (Chicago, IL)

May 6-10 The Plastic Show (Orlando, FL)

May 13-17 IEEE-ICRA (Yokohama, Japan)

June 4-5 Smart Manufacturing Experience (Pittsburgh, PA)

June 24-27 International Conference on Space Robotics (Luxemborg)

July 2-4 International Workshop on Robot Motion and Control (Poznan, Poland)

July 8-12 American Control Conference (Toronto, Canada)

Aug. 6-9 International Woodworking Fair (Chicago, IL)

Sept. 9-14 IMTS (Chicago, IL)

Oct. 1-3 International Robot Safety Conference (Cincinnati, OH)

Oct. 8-10 Autonomous Mobile Robots & Logistics Conference (Memphis, TN)

Oct. 15-17 Fabtech (Orlando, FL)

Oct. 16-17 RoboBusiness (Santa Clara, CA)

Oct. 28-Nov. 1 ASTM Intl. Conference on Advanced Manufacturing (Atlanta, GA)

Nov. 22-24 Humanoids 2024 (Nancy, France)