The Robots You May Never See: A Day in the Life of Tony

From toothbrush to takeout, an invisible army of machines quietly builds, moves, and delivers the world around us—one unnoticed motion at a time.

“The real problem is not whether machines think but whether men do.” — B. F. Skinner

Tony wakes to the alarm on his phone and shuffles toward the bathroom. He doesn’t know it yet, but his day is already crowded—with robots. Not the sci-fi kind with witty banter, the unglamorous kind that make, move, and manage the things he uses without ever asking for thanks.

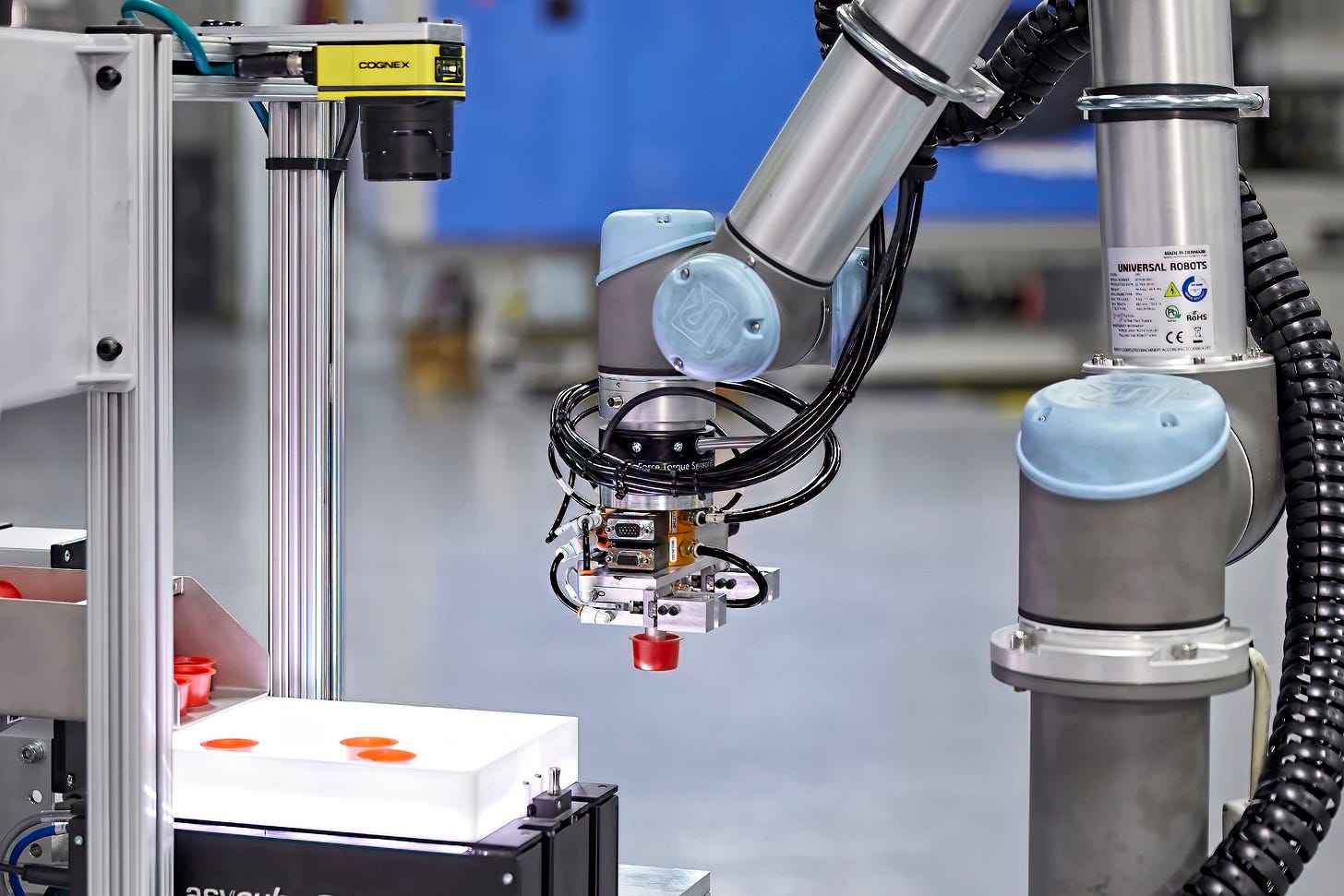

At the sink, Tony grabs his toothbrush. That simple, molded handle exists because a robot stood at the mouth of an injection-molding machine all night, repeating the same motions with unflinching precision. In many plastics plants, collaborative robots remove parts from hot molds, trim gates, and stage pieces for inspection—no coffee breaks, no singed fingers, just the sort of consistency that makes mass production affordable.

He pops the lid on his toothpaste and heads for the kitchen. Breakfast packaging is a minor miracle of speed. The foil lid on his yogurt, the carton around the eggs, the sleeve hugging his cereal box—somewhere, high-speed “delta” robots have been plucking, orienting, and placing light items whipping past on conveyors, doing in minutes what would take a crew of humans much longer at far higher injury risk. If you’ve ever watched a blur of three-armed “spider” robots at work, you know why food and consumer-goods lines swear by them.

Tony orders coffee beans and a new phone case before work. He taps Buy and thinks of it as “the internet.” What happens next is physical. Behind the app, a warehouse orchestrates fleets of mobile robots that ferry racks to people, robotic arms that sort items, and automated systems that right-size and seal boxes. Amazon alone says it has deployed more than a million robots across its network, from drive units and sortation systems to newer platforms—less a flashy stunt than an industrial heartbeat that hums under millions of orders a day.

The coffee beans in Tony’s cart? There’s a decent chance they’ll pass through a distribution center run by a global 3PL where robots handle the dull, heavy, awkward jobs humans tend to quit. DHL, for example, is rolling out more than 1,000 additional robots across the U.K. and Ireland as part of a £550 million upgrade—an investment that is as much about safety and retention as it is about throughput.

One of the last stubbornly manual jobs in warehouses has been unloading floor-loaded trailers—hot in summer, freezing in winter, boxes stacked to the ceiling. Even that is changing. Tony won’t see it, but a mobile robot called Stretch is already sliding into some trailers at DHL and other sites, vacuum arm grabbing cases and stacking them like Tetris. The tech is moving quickly: multipick features, higher sustained rates, better sensing for oddball boxes. It’s messy, real-world progress in a task long considered the “holy grail” of warehouse automation.

On the train, Tony scrolls his phone. That glass rectangle is a monument to invisible robots. In chip fabs, automated material-handling systems ride on tracks, shuttling sealed wafer pods—FOUPs—between tools with micrometer accuracy and zero fingerprints. FOUPs shield wafers from oxygen, moisture, and stray molecules; overhead hoist transport systems keep the flow relentless and clean. It’s a choreography of pods, load ports, and vacuum chambers that humans couldn’t maintain at modern yields.

At lunch, Tony walks a few blocks to a grocery store that delivers. The clerk mentions that their online orders are faster now. Somewhere behind that convenience is a grid—the “Hive”—where hundreds of robots skim along a lattice, surfacing bins for packing. Increasingly, robotic arms do part of the picking on-grid, learning to grasp slippery produce and crinkly bags that once defeated automation. Ocado, the U.K. company behind much of this tech and a key partner to Kroger in the U.S., now expects a growing share of orders to be robot-picked, with new systems rolling out across customer-fulfillment centers. Tony doesn’t need to know the acronyms; he notices his groceries arrive fresh and on time.

Back at his desk, his coworker compliments his sneakers. Funny thing about footwear: it shows how automation advances and retreats to find its edge. A few years ago, Adidas built “Speedfactories” in Germany and the U.S. to stitch a faster, more flexible, robot-heavy future for shoes—then shuttered them, moving the technology to Asian suppliers with deeper scale and supply chains. Automation didn’t “fail”; it learned to ride existing strengths rather than fight them. Today, cutting, knitting, gluing, and inspection are more automated, while skilled humans still win on final assembly where dexterity matters. Check out what ON is doing….

Back at home, he unboxes the phone case. The corrugate tab tears cleanly; the dunnage is right-sized; the label is straight. Every tiny detail screams “someone cared,” but that “someone” is usually a network of robots and people tuned together: a delta arm placing the insert just so; a vision system checking barcodes; a sorter kicking the parcel down the right chute. Tony snaps the case on his phone and tosses the packaging in the bin.

What Tony doesn’t see is just how human the value proposition is. The automation in plastics saves hands from hot molds—the trailer-unloading bots spare backs from heatstroke and repetitive strain. The fab transport systems keep people away from chemicals while protecting products too delicate for air. The grocery grid removes running and heavy lifting from pickers’ shifts. The result isn’t a “lights-out” world; it’s a gradual redistribution of effort, where machines grind through risk and repetition and people handle judgment, recovery, and the edge cases that refuse to become routine.

And the improvements compound. Robot arms keep getting better at “feel”—force control, softer grippers, and more innovative vision. Software stitches once-isolated cells into coherent flows. Big operators deploy across dozens of sites instead of dabbling in one facility at a time. Each quiet upgrade increases the odds that Tony’s order is correct, his package arrives faster, his work is safer, and the price doesn’t jump. The heroes of that story are the robots Tony never meets.

He sets his alarm and plugs in his phone. Somewhere, not far away, another robot is plugging along, too—tending a mold, unloading a trailer, sliding a pod onto a load port—so that tomorrow feels ordinary again.

Robot News Of The Week

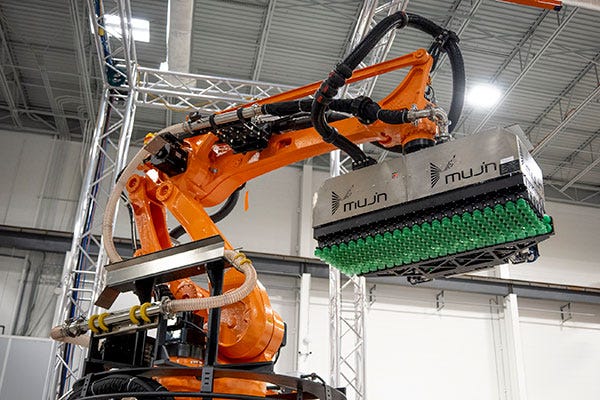

Industrial robots maker Mujin signs first North American partners

Mujin has partnered with eight North American automation firms to expand use of its MujinOS in warehouses and factories. The group includes integrators like Applied Manufacturing Technologies, Convergix, CRG Automation, Mesh Automation, and RG Group, plus material handling specialists C&B Material Handling, Conveyco, and Honeywell Intelligrated.

MujinOS uses a real-time digital twin to perceive, plan, and control robots without custom coding or rigid setups, enabling faster, more flexible automation for tasks like palletizing, bin picking, and mobile robot coordination. Partners receive hands-on training, direct technical support, and tools to scale deployments quickly.

Executives from both Mujin and its partners say the system boosts flexibility, reduces downtime, and accelerates large-scale automation. Mujin plans to add more integrators and distributors to make advanced robotics easier to deploy and maintain across industries.

Norway’s Saga Robotics harvests €9.5 million to grow its fleet of autonomous farm robots

Oslo-based Saga Robotics, maker of the Thorvald autonomous platform for grapevine and strawberry farming, has raised €9.5M (~$10.4M) to expand in the UK and US. The round included new investor Praesidium Agri-FoodTech and returning backers like Aker and Nysnø Climate Investments.

Thorvald—deployed for UV-C disease control, precision data collection, and other automated services—helps growers boost yields, cut labor costs, and reduce chemical use. Founded in 2016, Saga now has over 150 Thorvald 3.0 units in operation.

The raise, completed in two tranches (€6.6M in June, €2.9M in July), will fund rapid rollout. In the UK, Thorvald serves 13 major strawberry growers, covering ~20% of the market with a 30% target by 2026. In the US, it operates on 1,300+ vineyard acres, aiming to triple by 2026, and is approved for California’s CORE incentive grants.

Leadership changes include new board members Laila Danielsen (Elliptic Labs) and observer Alice Laurora (Praesidium). CEO Sacha de La Noë says the company is “entering a new phase focused on scale and impact.”

North American robot orders steady in the first half of 2025, reports A3

After a sluggish 2024, the North American robotics market rebounded in early 2025, according to the Association for Advancing Automation (A3). Robot orders rose 4.3% and revenue climbed 7.5% in the first half of the year compared to 2024.

Automotive OEMs led growth with a 34% jump in units ordered, but by Q2, non-automotive sectors accounted for 56% of orders, driven by life sciences (+22%), electronics/semiconductors (+18%), plastics/rubber (+9%), and other manufacturing. A3 cited reshoring, labor shortages, and efficiency demands as key drivers.

Collaborative robots (cobots) grew to 3,085 units worth $114M, making up nearly 24% of Q2 orders. These systems are designed to work alongside humans, particularly in labor- or space-limited settings.

A3 said the growth reflects automation’s role in building business resilience, flexibility, and competitiveness, and projected 2025 could outperform 2024 by mid-single-digit growth rates.

Robot Research In The News

Robots team up to explore planetary lava caves

Scientists tested a team of autonomous robots in a lava cave on Lanzarote, Spain, to see if they could one day explore similar formations on the Moon or Mars. Lava tubes—formed by ancient volcanic activity—could shelter astronauts from extreme temperatures, radiation, and meteorite impacts, and may even harbor signs of life.

Over 21 days, researchers deployed three different robots in four phases: mapping the cave entrance, using a sensor-equipped cube to create a 3D model, and sending a smaller rover rappelling into the cave with a larger one before navigating 235 meters inside to map its interior.

The trial showed the potential of cooperative robots for extraterrestrial exploration, though challenges remain—moisture-reduced radar performance, mapping was limited by sensor interference, and full autonomous cave navigation is still difficult. Even so, the work brings space agencies closer to scouting safe, viable locations for future human outposts beyond Earth.

Robots learn human-like movement adjustments to prevent object slipping

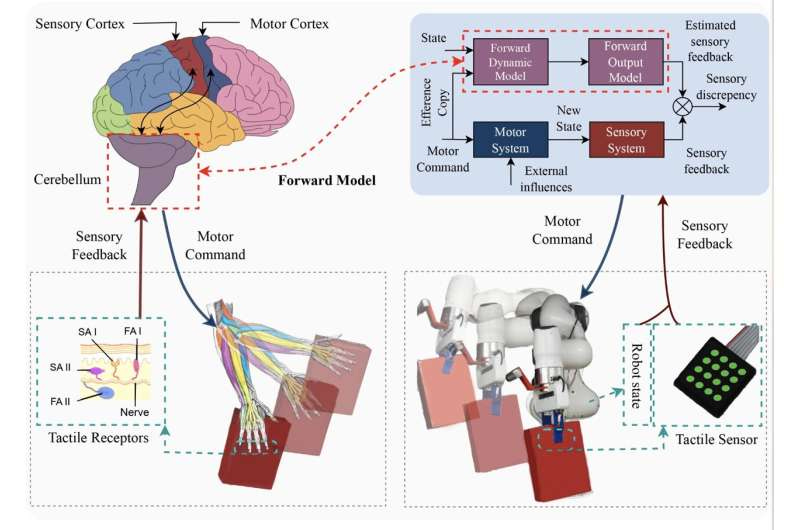

Researchers from the University of Lincoln, Toshiba Europe’s Cambridge Lab, the University of Surrey, Arizona State University, and KAIST have developed a bio-inspired robotic controller that prevents objects from slipping—not by squeezing harder, but by adjusting a robot’s movements in real time, much like humans do.

Instead of relying solely on grip force, the system uses a predictive “world model” to forecast tactile feedback and detect potential slips before they happen. The robot can then slow down, change direction, or reposition its hand to maintain a secure hold, reducing the risk of damaging fragile or slippery objects and working even when grip force can’t be altered.

Tested in dynamic, unstructured environments, the motion-based slip controller outperformed conventional force-only methods, marking two key breakthroughs:

The first motion-based slip prevention strategy to complement grip control.

A predictive controller using a learned tactile forward model for real-time slip forecasting.

The team aims to make the system faster, more efficient, and capable of handling complex, two-handed, or deformable objects, eventually combining tactile and visual data for broader real-world use in homes, factories, and healthcare.

Robot Workforce Story Of The Week

The Columbia Educational Robotics Foundation has opened a new Youth Robotics Center in Columbia, Missouri, providing mid-Missouri students a dedicated space to meet, build, and innovate.

At the ribbon-cutting, Columbia Public Schools Superintendent Jeff Klein and UM System President Mun Choi emphasized that robotics is about more than technology—it teaches collaboration, problem-solving, and resilience. The facility will serve teams from programs like FIRST Robotics, which offers hands-on, team-based STEM learning from pre-K through high school.

Local teams already using the space include the Army Ants FRC Team 3792 and FIRST Tech Challenge teams from Columbia’s public high schools. Alumni say the program builds confidence and communication skills. Data from FIRST shows its alumni are significantly more likely to study engineering or computer science, with especially strong gains for young women.

The center continues to add equipment and resources, aiming to inspire future STEM careers while strengthening teamwork and leadership among local youth.

Robot Video Of The Week

With all eyes on the World Robot Conference, our Video of the Week practically chose itself. The exhibition pulled in 200+ companies and unveiled more than 1,500 cutting-edge demos—from surgical bots to warehouse workhorses. But the real showstopper? A record 50 humanoid robot makers sharing their latest strides in locomotion, dexterous hands, and real-time AI control. If you want a snapshot of where embodied AI is headed—faster, cheaper, more capable, and far more human-aware—this year’s WRC delivered it in spades. Grab the popcorn; the humanoid era is accelerating.

Upcoming Robot Events

Aug. 25-29 IEEE RO-MAN (Eindhoven, Netherlands)

Sept. 2-5 European Conference on Mobile Robots (Padua, Italy)

Sept. 3-5 ARM Institute Member Meetings (Pittsburgh, PA)

Sept. 15-17 ROSCon UK (Edinburgh)

Sept. 23 Humanoid Robot Forum (Seattle, WA)

Sept. 27-30 IEEE Conference on Robot Learning (Seoul, KR)

Sept. 30-Oct. 2 IEEE International Conference on Humanoid Robots (Seoul, KR)

Oct. 6-10 Intl. Conference on Advanced Manufacturing (Las Vegas, NV)

Oct. 15-16 RoboBusiness (Santa Clara, CA)

Oct. 19-25 IEEE IROS (Hangzhou, China)

Oct. 27-29 ROSCon (Singapore)

Nov. 3-5 Intl. Robot Safety Conference (Houston, TX)

Dec. 1-4 Intl. Conference on Space Robotics (Sendai, Japan)

Dec. 11-12 Humanoid Summit (Silicon Valley TBA)

Mar. 16-19 Intl. Conference on Human-Robot Interaction (Edinburgh, Scotland)