What Journalism Gets Wrong About Robotics and Automation

There is a lot of talk about Automation around the current ILA strikes; many journalists are failing at basic facts around Automation and that is not helping either side

Aaron’s Thoughts On The Week

“When the legend becomes fact, print the legend.” - Quote from the movie “The Man Who Shot Liberty Valance”

I have been interviewed numerous times by reporters on the topic of robotics and automation. It takes me no more than 5 minutes to gauge if the reporter has an agenda or is really just trying to get insights from someone in the field to actually deliver a well-rounded article. Over the years now I have noticed that more reporters are trying to get more to the point of understanding automation better and what it can and cannot do. There have also been, at least for me, more reporters questioning if robots and automation are the job killers that they have been painted as. So, it has been encouraging to see that the conversation appeared to have finally moved more to a fact-based discussion on the topic and less on “emotions.” Then a national event happens and all of that is thrown out the window.

The Longshoremen Go On Strike Closing Seaports

The ILA (International Longshoremen's Association) port strike began on October 1, affecting 36 major ports along the U.S. East and Gulf Coasts. Nearly 50,000 dockworkers are protesting over issues like wages, job security, and the impact of automation. This strike has the potential to severely disrupt supply chains, causing delays and price increases. Labor shortages and disputes over the adoption of new technologies, such as robotics and automation, are central to the conflict. The strike could have significant economic implications if it continues, so of course, the strike is being covered by everyone and anyone - including reporters who don’t know much about robotics and automation.

So once again we have reporters looking for information surrounding the concerns raised by the striking workers. In nearly all of the major reports on the strike, I’ve seen the same report listed over and over again - a 2022 study by the Economic Roundtable of Los Angeles - that supports the ILA’s assertions that automating the Ports would cost jobs. The one major issue with the report, though, is it was commissioned by (checks notes)…the ILA.

Many have pointed out this glaring issue, and I have seen some articles updated to note that the study was indeed commissioned by the ILA. However, this was nearly 24 hours after publication, which means that many readers probably didn’t see the critical correction.

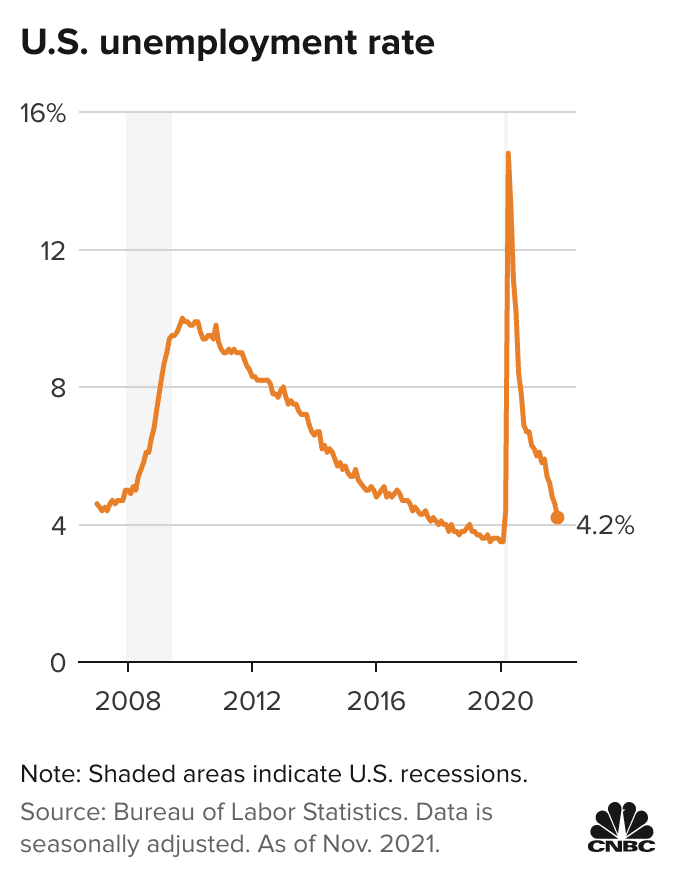

The other major issue is the key finding of dockworkers losing jobs in two critical years - 2020 and 2021. The ILA report blames this on Automation, but one has to wonder if many of those jobs were lost due to (check notes again) a GLOBAL PANDEMIC like other jobs that were lost. One only needs to look at the unemployment rate at the time to come up with a better reason why there were lost jobs at the ports, because there were lost jobs everywhere in those years.

There are also two other questionable parts in the ILA report. One claim is that automated ports are less productive, however, the ILA does not provide data to back that claim. Then there is the claim that only 4% of ports are automated. This one cuts two ways. First, there is tons of other data that says that number is much higher and this may be due to how “automation” is defined by those conducting the study. This leads to the second issue: if the ILA is saying they only see 4% of ports as automated - do they really understand what automation truly is, and if it is that low of a number, why are you concerned if a bit more is added?

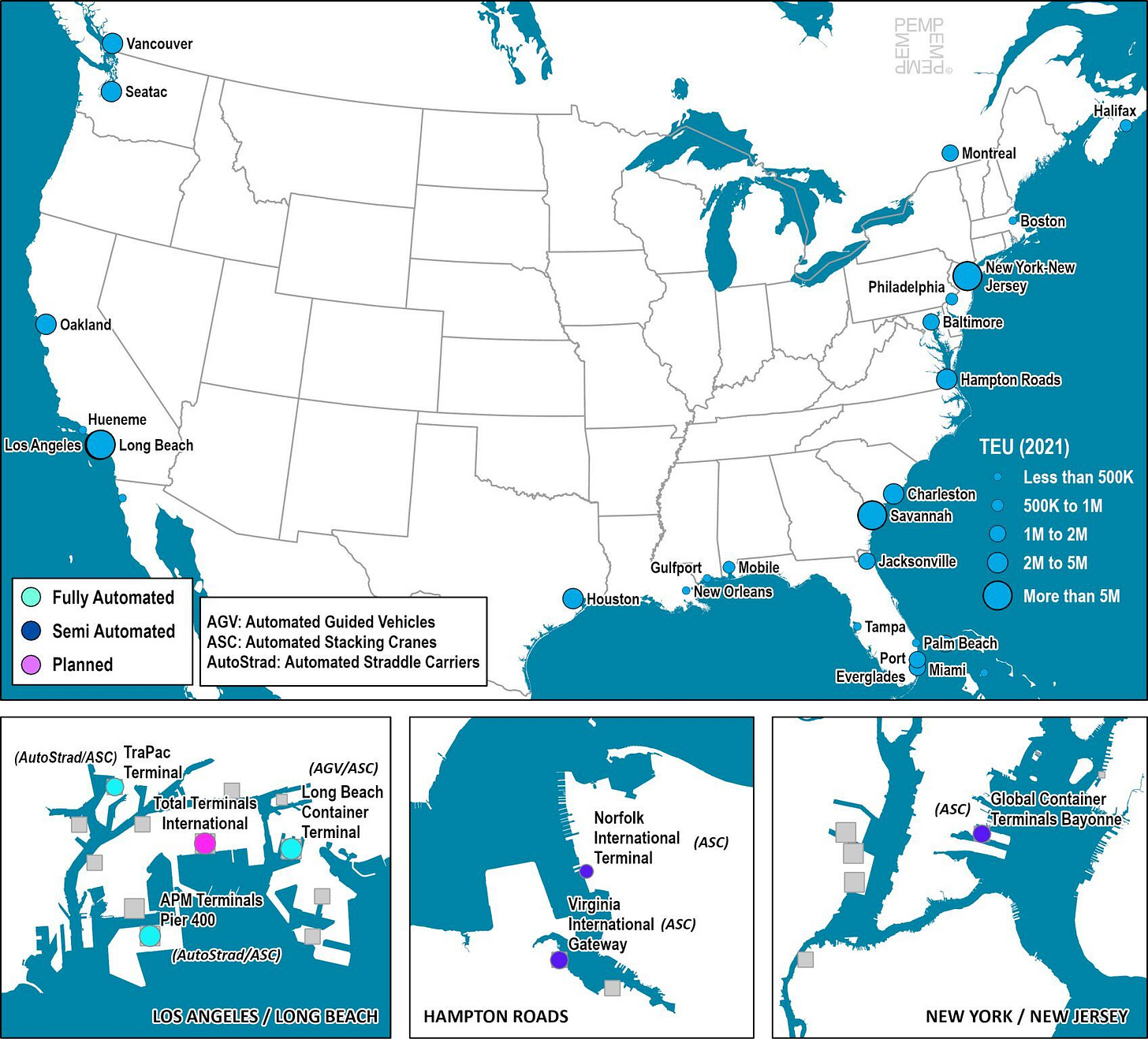

I was able to do a quick ChatGPT inquiry about the number of automated ports in the US and got the following information and map.

Six container terminals use automation—three on the West Coast (LA/LB) and three on the East Coast (New York and Hampton Roads). Automation relies on Automated Stacking Cranes (ASC) for yard operations and Automated Guided Vehicles (AGV) or AutoStrads for ship-to-yard transport. West Coast terminals are fully automated, covering both ship-to-yard and yard operations. East Coast terminals are semi-automated, focusing on yard operations only. This excludes automated gate technologies used for truck processing.

It should be noted that the ILA walked away from the negotiations because of the “discovery” of an automated gate at the Mobile, Alabama port. As shown from the ChatGPT inquiry, its cited source stated that automated gates were not considered automation. I would agree with that. Many of us have automated garage doors at home, many of us would probably not call that “automation” per se. So again, what does the ILA consider “automation” should be the question reporters are asking. Especially after one reported hunted down the gate in Mobile and found that the gate has been in operations for 16 years when the terminal was first built!

What Many Journalists Get Wrong About Robotics And Automation

In my opinion, there are three common ways journalists fail when explaining robotics and automation to the general public. They are:

Overhyping Capabilities: Journalists often exaggerate the current capabilities of robots and automation, making it seem like fully autonomous, human-like robots are commonplace. This leads to unrealistic expectations, overshadowing the actual, more gradual progress in areas like industrial robotics or AI-based systems, which are often specialized and limited in scope.

Using Technical Jargon: Journalists sometimes fail to simplify complex concepts, using technical terms (like "machine learning algorithms" or "reinforcement learning") without adequately explaining them. This leaves readers confused about how robots or automation systems work and their real-world applications, making the technology seem more mysterious or intimidating than it is.

Overemphasizing Job Loss: While automation and robotics do impact certain jobs, many journalists focus disproportionately on the narrative of robots "stealing jobs" without balancing it with information on how these technologies create new opportunities, enhance productivity, or help in dangerous and repetitive tasks. This sensationalized focus can fuel fear and misunderstanding about the broader role of automation in society.

Many of you will likely have your own examples of when you have read or watched a journalist make one of these mistakes.

Overhyping the technology is nothing new. We see it all the time now around humanoid robotics. Now, many journalists are just repeating the hype that many CEOs and VCs are saying, but again - do some homework.

When XPrize Foundation founder Peter Diamandis (and others) predicted that millions or even billions of humanoid robots could exist by 2050, there was nearly no pushback even though one could easily do so with one stat - there is just over 4 million industrial robots as of the end of 2023. If we maintained 10% growth, by 2050 we would still only have 55 million robots based on the current type of robots we are counting, let alone humanoids.

This lack of pushback or simple fact-checking by many journalists sometimes leads to poor use of technical jargon and falling into the “robots kill jobs” camp. With marketers now slapping “AI-enabled” on everything and anything, we need journalists asking what AI is and what it is not. This allows overhype to happen, journalists not challenging the marketing and showing the reality.

This lack of challenge in what is being said and what is happening also applies to the claims that robots and automation are killing jobs. Of course, robots and automation do shake up the industries they are introduced into. Some jobs are lost, but this only sometimes results in long-term unemployment. Many workers are re-utilized elsewhere or train for new careers elsewhere. We have been automating things for decades, and one would think if the claims of automation destroying jobs were true then all of us would be out of a job by now….but we are not.

While many reports focus on the potential negative impact of automation on jobs, experts also highlight its benefits. According to PWC's Global Artificial Intelligence study, AI could boost global GDP by 26% by 2030, with productivity gains driving 40% of this growth. Although some jobs may be lost, PWC believes that new job creation from a wealthier economy will balance the losses. The World Economic Forum's 2020 report supports this, estimating that while 85 million jobs may be displaced, 97 million new ones will emerge. Studies further show automation often leads to job creation. After all, 60% of the jobs we know today didn’t exist a generation ago.

There Are Experts To Discuss This With

The good news, as mentioned at the start of this article, is that many reporters are contacting those of us in the Robotics and Automation industry more to get our thoughts and data to help them tell a complete story. Now, while I wish there were many more Steve Crowes, Eugene Demaitres, Mike Oitzmans, and Brianna Wesslings (all of which you should follow) covering our industry, there simple are not and will never be enough that have that level of knowledge about our industry. However, that does not mean we can’t help educate them through facts and real stories of automation successes.

I hope that more reporters reach out to organizations like A3, the International Federation of Robotics, and us standards organizations like UL, ISO, and ASTM. All of these organizations can provide experts on the topic of automation very quickly - you just need to ask.

So What Would I Ask The ILA?

To close this discussion out, I will provide a few questions I would like to see journalists ask the ILA and the Port Managers.

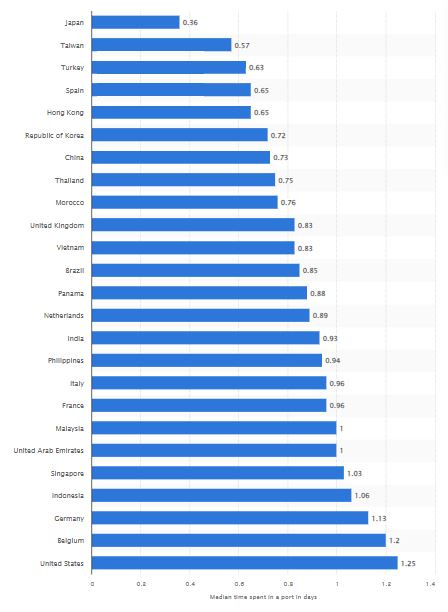

Why Does It Take The US The Longest To Turn A Cargo Ship?

According to Statista, the average time for a cargo ship in a US port to be offloaded and reloaded takes 1.25 days, which is dead last amongst the 25 countries they looked at. Japan had the best time of 0.36 days to do the same thing. Why is Japan so much faster? Why is EVERYONE ELSE faster?

Why Do US Port Workers Make More While Also Having More Automation?

The ports on the US West Coast are staying open during this strike, due to already having a deal and interestingly more automation than the East Coast and Gulf ports that are striking. The ports of Los Angeles and Long Beach have led the way in implementing automation among U.S. ports. Data from 2015 to 2021 shows the workforce in the Los Angeles and Long Beach ports experienced an 11.2% growth, surpassing the 8.4% growth seen at other West Coast ports. So due to the addition of automation, they can process more. So what about pay and hours?

During this same period, the two automated terminals saw a significant 31.5% increase in paid hours, while non-automated terminals only experienced a 13.9% increase. The substantial difference in paid hours was attributed to efficiency improvements that allowed them to process more than twice the number of containers compared to their non-automated counterparts.

So hours and pay went up with Automation. That is a fact, so what again is the concern of the ILA?

It Is Estimated That Amazon Has Close To 1 Million Robots, But Employees 1.5 Million People And Is About To Hire An Additional 250,000 For The Holidays. Why Wouldn’t We See The Same For Ports?

Isn’t a port just another big warehouse operation? So if Amazon can use a MILLION robots and still employee even more people, then how do robots kill jobs?

Similarly, how many “jobs” has that smartphone in your pocket destroyed?

We all benefit from Automation, in all of the different forms it can take. It is time to start realizing the hypocrisy of reaping the benefits of automation, but then getting angry when it may be targeting to us. I know I was happy when my so-called job as a 6-year-old was being a remote control was eliminated by technology. And I’m pretty sure my kids are happy that job was also automated.

Robot News Of The Week

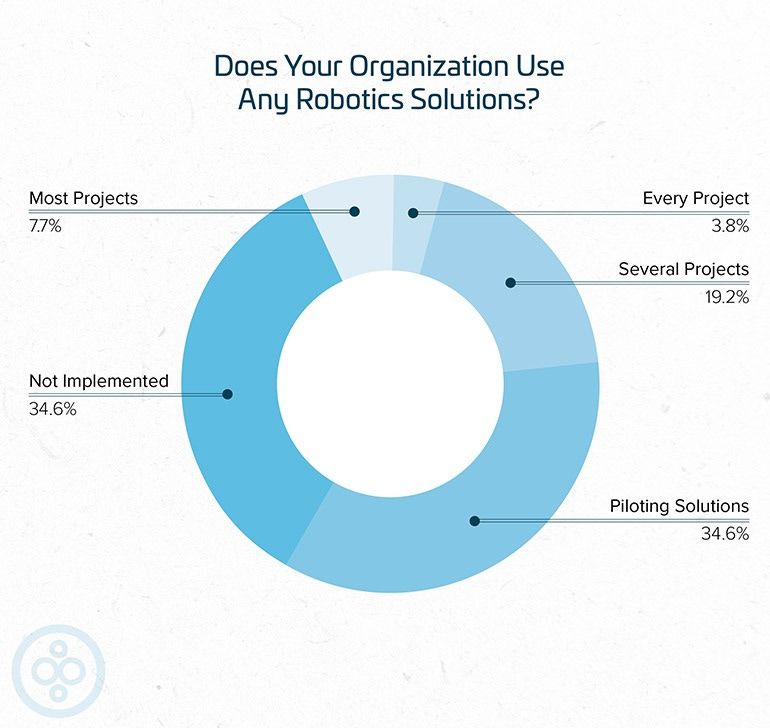

BuiltWorlds reports that the construction industry may be warming to robotics

The construction industry, historically slow in adopting new technologies, is beginning to embrace robotics, according to the 2024 “Tools, Equipment, and Robotics Benchmarking Report” by BuiltWorlds, a Chicago-based network focused on innovation in architecture, engineering, and construction (AEC). The report notes significant progress, particularly in the adoption of monitoring and service/labor robotics, with nearly two-thirds of contractors using these technologies. However, areas like autonomous heavy equipment (35%) and prefabrication robotics (6%) are less common.

Labor shortages, with over 500,000 open positions in construction, are a primary driver for increased robotics utilization. Additionally, advancements in BIM (Building Information Modeling), improved data collection, and a cultural shift towards technology have helped reduce traditional barriers to adoption.

Dusty Robotics, a leader in layout robotics, was highlighted as one of the most implemented and highest-rated providers in the report, excelling in ease of use, speed, and quality. Despite progress, challenges remain, including the cost of robotics, underutilization of BIM, and the industry's risk-averse nature. Although widespread adoption is still distant, robotics offers significant potential to improve safety, efficiency, and productivity in construction.

US Army Testing Robot Dogs Armed with Artificial Intelligence-Enabled Rifles in Middle East

The U.S. Army has deployed a "robot dog" armed with an AI-enabled gun turret for testing in the Middle East to enhance counter-drone capabilities. The Ghost Robotics Vision 60 Q-UGV, equipped with an AR-15/M16-style rifle, was tested at the Red Sands Experimentation Center in Saudi Arabia. This development is part of the Army's efforts to integrate robotic systems into combat, including tasks like explosive ordnance disposal and perimeter security. The Army aims to provide cost-effective solutions to counter drone threats through autonomous weapon systems, but deployment alongside U.S. troops is not guaranteed.

Self-Flying Drones, Self-Driving Robots Combine to Deliver in Dallas

Self-flying drones and self-driving robots are teaming up to deliver food in Dallas. Wing, Alphabet's drone delivery service, has partnered with Serve Robotics, a maker of autonomous sidewalk robots, to enhance delivery efficiency. The FAA has granted Wing and Zipline permission to manage their airspace in North Texas, allowing for deliveries beyond visual line of sight. The partnership aims to combine Serve's robots and Wing's drones to cover more areas and improve delivery speed, enabling 30-minute deliveries across the city. Serve robots will pick up orders curbside and bring them to Wing’s Autoloaders for drone pickup. The partnership aims to streamline delivery with integration into apps like DoorDash and Walmart for ease of use.

Study shows positive sentiment for in-store robots

Simbe, a San Francisco-based store intelligence solutions provider, revealed that over 75% of shoppers have a positive view of in-store robots. Their platform, which uses AI, computer vision, and the autonomous robot Tally, helps retailers improve the shopping experience by addressing issues like inconsistent pricing and out-of-stock inventory. Simbe also announced a new partnership with CarrefourSA in Turkey, adding to their global presence. Retailers like BJ’s Wholesale, SpartanNash, and others have seen significant benefits from using Simbe’s solutions.

Robot Research In The News

Engineers teach a quadruped robot to climb standard ladders

A team at ETH Zurich's Robotics Systems Lab modified the ANYMal robot to efficiently climb ladders using custom "paws" with a hook-like gripping mechanism. The robot was trained using reinforcement learning and simulations, achieving a 90% success rate in real-world tests. The team aims to further develop the robot's ladder-climbing capabilities for unstructured environments without the need for motion capture tools.

AI-generated images can teach robots how to act

Researchers from Stephen James’s Robot Learning Lab in London have developed a new system called Genima, which uses image-generating AI models to create training data for robots. Genima aims to improve how robots learn movements by using images as both input and output, making the process more interpretable and easier for robots to understand. The system overlays data from robot sensors onto images captured by cameras, visualizing desired actions through colored spheres that indicate where the robot’s joints should move. In tests with robotic arms, the system had success rates of 50% in simulations and 64% in real-world tasks. The team is optimistic about Genima's potential and its wide range of applications, from domestic tasks to various robot types.

Robot Workforce Story Of The Week

OnlineMetals, an e-commerce leader in the metal and plastics industry, has launched a Sponsorship Program to support mechanical engineering and robotics programs in U.S. high schools and colleges. The initiative provides selected institutions with credits to purchase high-quality materials, enabling students to bring their innovative projects to life.

Greg Raece, President of OnlineMetals, emphasized the company's commitment to nurturing future engineers and innovators. One beneficiary is Ballard High School’s Viking Robotics team in Seattle, where OnlineMetals' support has helped the students build competitive, real-world machines instead of makeshift robots. Lead mentor Brent Schultz noted that OnlineMetals has been essential in providing materials and guiding students in material selection.

Schultz’s stepdaughter, Cecilia Kalthoff, a research scientist, returned as a mentor after graduating, highlighting how the program has helped her develop valuable engineering skills. The program encourages U.S. high school and college teams to apply for sponsorship, offering materials credits or cash sponsorships. Participants are invited to share their projects on social media using @OnlineMetals and #madewithmetal to connect with the broader community.

Robot Video Of The Week

Who doesn’t love a cute robot? Lavazza takes us to a not-so-distant future where an adorable, Wall-E-like robot zooms around the office, serving up espressos, lattes, and cappuccinos to workers in need of a pick-me-up. Naturally, he's a hit with everyone!

But when the office clears out, our little hero gets curious and tries some coffee himself. One tiny droplet sends him into a delightful daydream—a classic Italian getaway with his coworkers, featuring beaches, galleries, and even gondolas! The message? "Pleasure makes us human."

And just when you think it's all over, the robot wakes up... but he's not alone! He’s joined by two iconic ‘Office’ workers, giving us the perfect happy ending. ☺️

Upcoming Robot Events

Oct. 7 Humanoid Robot Forum (Memphis, TN)

Oct. 8-10 Autonomous Mobile Robots & Logistics Conference (Memphis, TN)

Oct. 14-18 International Conference on Intelligent Robots and Systems (Abu Dhabi)

Oct. 15-17 Fabtech (Orlando, FL)

Oct. 16-17 RoboBusiness (Santa Clara, CA)

Oct. 21-23 ROSCon (Odense, Denmark)

Oct. 23-26 International Conference on Social Robotics (Odense, Denmark)

Oct. 28-Nov. 1 ASTM Intl. Conference on Advanced Manufacturing (Atlanta, GA)

Nov. 22-24 Humanoids 2024 (Nancy, France)

Jan. 21-24 Intl. Symposium on System Integrations (Munich)

Mar. 4-6 Intl. Conference on Human-Robot Interaction (Melbourne)

Mar. 21-23 Intl. Conference on Robotics and Intelligent Technology (Macau)

May 12-15 Automate (Detroit, MI)

May 17-23 ICRA 2025 (Atlanta, GA)

May 18-21 Intl. Electric Machines and Drives Conference (Houston, TX)

May 20-21 Robotics & Automation Conference (Tel Aviv)

Aug. 18-22 Intl. Conference on Automation Science & Engineering (Anaheim, CA)

Thanks for the shoutout, Aaron! We work hard to cover robotics objectively. Sure, there are economic challenges, and workers need protection and retraining. Digging through the statistics, there's no correlation between automation and unemployment. Moving manufacturing overseas in pursuit of cheap goods and maximized profits was far worse. We've seen that robots augment human capabilities, allowing people to focus less on the dull, dirty, and dangerous tasks and more on their unique value-added jobs.