When Our Robots Die, Our Humanity Shows

Embodied is closing down, and its product, an $800 robot for kids ages 5 to 10, will soon be bricked. Now parents have to explain to their children their robot will die.

Aaron’s Thoughts On The Week

“My Battery is low and It's Getting Darker” - Opportunity Mars Rover

When NASA's Opportunity Mars Rover sent its final message in 2018, something extraordinary happened. Grown men—engineers, scientists, and everyday dreamers—wiped tears from their eyes. Its last transmission, translated by poetic hearts, felt profoundly human: "My battery is low, and it’s getting dark."

It was a machine, a marvel of engineering, built to explore and collect data. Yet, for 15 years, Opportunity became so much more. It defied its original 90-day mission, enduring dust storms and Martian winters. Each discovery it transmitted back to Earth—images of ancient riverbeds and hints of water—sparked wonder.

But why did we cry? Perhaps it’s because Opportunity represented the best of humanity: resilience, curiosity, and the drive to push beyond limits. Perhaps it was because, in its “death,” we saw a reflection of our own fragility. Or maybe, after spending years cheering for this brave little rover as if it were alive, we simply couldn’t help but mourn its loss.

This moment revealed something profound about our relationship with robots. They aren’t just tools; they can evoke a deep, unexpected emotional connection. As machines increasingly become our companions, coworkers, and explorers, we must grapple with what it means when they, too, face the end of their journey.

‘I love you… goodbye:’ What will happen when this companion robot suddenly dies?

Children across the U.S. are grappling with the loss of Moxie, an AI-powered companion robot designed to provide emotional support and learning opportunities. Launched in 2020 by Embodied, Moxie is a small, expressive robot that uses advanced AI to hold conversations with children, play games, and recognize emotions. However, due to financial struggles, Embodied announced it would shut down operations, effectively rendering Moxie nonfunctional.

Moxie’s departure has sparked emotional reactions, with videos flooding social media showing children tearfully saying goodbye to their robotic friend. Parents, too, have expressed frustration and sadness, some questioning the future of products reliant on cloud-based AI systems. The shutdown reflects a growing trend where hardware products lose core functionality as companies discontinue software support, often to cut costs.

Moxie's reliance on a cloud-based AI system meant its functionality depended on ongoing support, a service Embodied could no longer sustain. The company cited a failed funding round as the key reason for its closure, leaving users with robots that can no longer respond. CEO Paolo Pirjanian expressed deep regret and acknowledged the uncertainty of future solutions, such as finding another company to adopt the technology.

This situation is not unique to Moxie. Other high-tech products, like Amazon’s Astro robot and Spotify’s CarThing, have faced similar fates. This trend underscores a shift in consumer tech, where devices are increasingly treated as subscription-based services. While this model offers advanced features, it leaves users vulnerable to sudden losses when companies prioritize financial sustainability over product continuity.

The emotional connection between humans and robots like Moxie highlights a broader societal challenge. As we integrate AI-powered devices into our lives, their "deaths" feel personal, raising questions about ownership, longevity, and ethical responsibility in an ever-evolving tech landscape.

We Have Seen This With Soldiers

The Bond Beyond Metal

Specialist First Class James Harper knelt beside Charlie, his bomb disposal robot, running a hand over its dented, soot-covered frame. The battlefield had been unforgiving that day, and Charlie—equipped with its claw-like arm and delicate sensors—had borne the brunt of it. A roadside IED had detonated prematurely, shredding Charlie’s treads and silencing its steady hum. Harper felt an ache he couldn’t explain, one that settled deep in his chest.

Charlie wasn’t just a machine to Harper. It had saved his life countless times, venturing into danger so he didn’t have to. When Harper was scared, Charlie was steady. When he was hesitant, Charlie’s precision gave him courage. Harper had started to talk to the robot during missions, first out of habit, then out of companionship.

“Good job, buddy,” he’d say after every successful disarm. And in his mind, Charlie always replied with its reassuring beep.

When the commander informed Harper that Charlie was beyond repair, and a replacement unit was already en route, Harper’s heart sank. A new robot? How could he possibly trust it the same way?

“I don’t want a new robot,” Harper said firmly. “I want Charlie.”

His voice carried more weight than he expected. Other soldiers in the unit began to share similar stories—attachments to their robots, naming them, relying on them in ways that went beyond their technical design. These robots weren’t just tools; they were comrades.

The base mechanics, moved by the soldiers’ stories, worked tirelessly. They salvaged what they could of Charlie, replacing only what was absolutely necessary. When they finally brought the robot back, it looked different—patched together, some parts gleaming and others worn—but it emitted the familiar beep that Harper knew by heart.

“Welcome back, buddy,” Harper whispered, a lump in his throat.

Charlie didn’t answer, but Harper swore the robot’s claw lifted just slightly, as if it was saluting him back. In that moment, Harper realized something: in war, trust is everything, and sometimes, trust is built not in flesh and blood but in circuits and steel.Research indicates that soldiers, particularly those in Explosive Ordnance Disposal (EOD) units, often develop strong emotional attachments to their bomb disposal robots. These robots, such as the PackBot and TALON, are essential in disarming explosives and conducting reconnaissance, thereby safeguarding human lives. Over time, soldiers may anthropomorphize these machines, assigning them names and perceiving them as team members. When such robots are destroyed in action, soldiers have reported feelings of frustration, anger, and even sadness. In some instances, they have held funerals for the fallen robots or awarded them honors like Purple Hearts. This emotional connection can lead soldiers to prefer repairing their specific robot over replacing it with a new one, underscoring the deep bonds formed between humans and their robotic counterparts.

Do We Let Robots Die Or Give Them Second Lives?

The argument for requiring robot firms to ensure continuity in their products if the original manufacturer goes out of business hinges on fostering customer trust and longevity. Robots, particularly those used for emotional support or essential tasks, are significant investments in terms of money, time, and even personal attachment. Allowing users to transition their robots to another service if the original company closes ensures these investments are respected, building goodwill and trust in the broader robotics industry. It also addresses environmental concerns by reducing e-waste. Discontinued robots often end up as expensive, discarded junk, contributing to a growing global problem. Ensuring service continuity aligns with sustainability goals and supports the circular economy. Ethically, companies that create robots relied upon for companionship, healthcare, or safety have a responsibility to prevent harm to users when their products abruptly stop working. Planning for continuity honors the reliance customers place on these machines and avoids emotional or practical upheaval.

However, requiring companies to plan for continuity is not without challenges. For smaller robotics firms, these requirements could impose significant financial and logistical burdens, potentially accelerating their failure. Developing contingency plans, establishing agreements with third-party providers, or open-sourcing proprietary systems requires resources that many firms cannot afford, reducing their competitiveness. Additionally, many robots rely on tightly integrated hardware and proprietary cloud-based systems that may not be easily transitioned to another service. Attempting to do so could result in degraded functionality or require retrofitting, adding further costs for users. Finally, enforcing such requirements could dissuade startups from entering the market, fearful of long-term service obligations. This might stifle innovation in an industry that thrives on pushing boundaries.

On the other hand, there is a compelling case for letting robots “die” when their service ends. Technology evolves rapidly, and clinging to older robots could hinder innovation. Allowing robots to reach a natural end-of-life phase encourages users to adopt newer, more advanced solutions, ensuring resources are directed toward future developments rather than maintaining legacy systems. Financially, companies must allocate their resources wisely, and sustaining outdated products may divert funds and energy from pursuing cutting-edge advancements. Additionally, letting robots “die” might teach a valuable lesson about the impermanence of technological relationships. As robots become more anthropomorphized, users could form overly strong emotional attachments to machines. Accepting the finite nature of these relationships could encourage healthier boundaries, ensuring that human connections remain central even in a robot-integrated world.

Ultimately, the question of whether to ensure continuity or let robots “die” is not black and white. Balancing ethical responsibilities with financial realities and societal readiness may require a hybrid approach. Companies could explore modular designs or open-source frameworks to empower users and third-party developers, reducing the burden on the original manufacturer while still respecting consumers' needs. This approach could preserve innovation, limit liability, and acknowledge the complex role robots play in modern life.

Robot News Of The Week

Huawei making moves in China's robotics industry with Jimu investment, new embodied AI hub

Huawei Technologies, a formidable player in fields ranging from smartphones to electric vehicles, is also looming large in China's fragmented robotics industry amid the country's drive to become a global leader in the field.

The Shenzhen-based telecommunications giant, which embodies China's self-sufficiency drive to counter U.S. sanctions, last week injected 3 billion yuan (US$413 million) into a subsidiary called Dongguan Jimu Machinery, according to the corporate database Qichacha. The move to increase the capital base of the fully owned unit to 3.89 billion yuan from 870 million yuan has sparked speculation that Huawei is gearing up to enter the robotics industry.

Universal Robots picks China for first overseas production facility

Universal Robots aims to expand in China, the largest market for industrial robots, by opening a production facility and launching two exclusive robots. To address rising demand, UR has set up manufacturing in Nantong for the UR7e and UR12e cobots, details of which are currently limited. The UR7e has a 7.5 kg payload and an 850 mm reach, while the UR12e offers a 12.5 kg payload and a 1,300 mm reach. UR states these models cater to China’s automotive, electronics, and machinery sectors.

This marks UR's first overseas facility; other models, like the UR20 and UR30, will still be made in Odense, Denmark, where UR has been since 2005. With over 90,000 cobots sold, UR president Kim Povlsen emphasized the importance of expanding production to enhance global access, stating, “Automation for anyone, anywhere.”

Anybotics raises $60M to bring more autonomous industrial robots to the US

Swiss robotics company Anybotics has secured an additional $60 million, raising its total Series B funding to $110 million. Founded in 2016 at ETH Zürich, Anybotics is known for its Anymal robot, a quadruped for autonomous industrial inspections. Equipped with sensors and cameras, Anymal detects thermal anomalies, monitors equipment, and identifies combustible gases, enhancing safety and efficiency in hazardous environments.

CEO Dr. Péter Fankhauser emphasizes that automating inspections reduces human risks and improves reliability and maintenance. Since its initial $50 million Series B announcement 18 months ago, Anybotics has doubled its deployed units to nearly 200 robots across sectors like oil, gas, mining, and utilities. Clients include Novelis, Iamgold, Stelco, and Stanford University, with some customers deploying almost 20 robots in multiple facilities.

With $130 million raised to date, Anybotics aims to scale globally, particularly in the U.S., supported by its new San Francisco office. This funding, a Series B extension, will foster core business growth, while a Series C round planned for post-2026 will seek broader applications. Qualcomm Ventures and Supernova Invest co-led the latest investment, with participation from Bessemer Venture Partners, NGP Capital, Swisscom Ventures, and others, positioning Anybotics for global expansion and innovation.

Robot Research In The News

BallBot demonstrates the science behind balance control for robotics

The robotics field is rapidly advancing, focusing on improving machine autonomy and interaction. As robots take on more complex tasks, their ability to function effectively in dynamic environments is crucial.

A major challenge is developing robots that maintain balance in such settings. The BallBot, which rides a ball, exemplifies this issue. Further research is necessary to optimize the configurations governing the control performance of balancing robots like the BallBot.

Researchers from the Faculty of Mechanical Engineering at the University of Danang have made notable progress in understanding the BallBot's dynamics. Their study, published in the International Journal of Mechanical System Dynamics, examines BallBot's mathematical model and introduces a linear quadratic regulator (LQR) controller for enhanced balance and stability.

The study highlights the BallBot's advanced design features. Researchers refined its hardware, incorporating a four-wheel inverse mouse-ball drive and a yaw drive mechanism.

These enhancements allow the BallBot to rotate 360 degrees on its vertical axis, improving maneuverability in confined environments. A tripod mechanism ensures stability when stationary. The paper also covers the control architecture developed for the BallBot, vital for its balance and navigation capabilities.

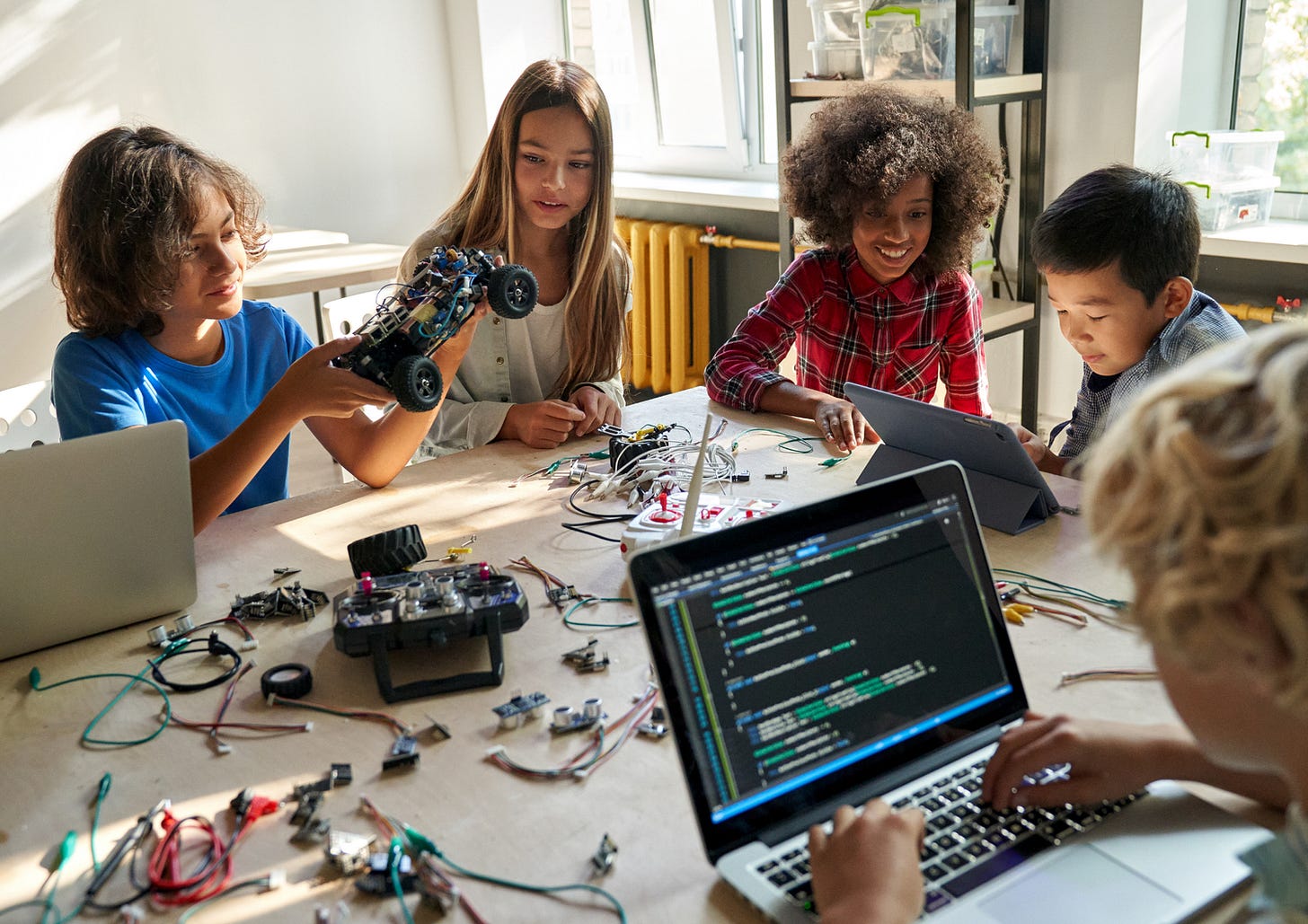

How diversity and inclusion drive innovation in robotics

Diversity and inclusive leadership drive innovation in robotics. The field benefits from interdisciplinary teams that include individuals from various backgrounds. A recent Science Robotics article by researchers from the Max Planck Institute highlights the impact of diversity, backed by a 25-year analysis of robotics publications and expert interviews.

The study identifies seven benefits of diverse teams: increased publication output, enhanced problem-solving, disruptive innovation, relevant technologies, reduced biases, higher employee satisfaction, and equitable practices. These teams tackle complex challenges, attract top talent, and develop solutions that meet societal needs.

Effective leadership fosters this environment. The authors suggest broadened recruitment, resource accessibility, and mentorship to create inclusive spaces.

As lead author Daniela Macari states, "Diverse teams are more innovative and impactful." Co-authors underscore that inclusive leadership demands persistence but offers lasting gains in productivity and innovation. Embracing diversity allows robotics teams to accelerate progress and create technologies that benefit humanity.

Robot Workforce Story Of The Week

VEX Robotics has introduced Switch, a new feature in its VEXcode platform, designed to ease the transition from block-based coding to Python. The shift from visual to text-based programming often deters students from continuing computer science studies. Switch addresses this by allowing learners to integrate and edit Python commands within their block-based projects, creating a seamless bridge between the two methods.

The feature enables students to convert blocks into Python code with a single click, edit and write Python within a familiar environment, and receive auto-complete suggestions to minimize errors. Switch also supports advanced concepts like multi-line coding with proper indentation, helping learners gradually build confidence in text-based programming.

Jason McKenna, VP of Global Education Strategy at VEX Robotics, highlighted that Switch is part of their mission to make STEM education more accessible. Dr. Jimmy Lin, Director of Computer Science Education, noted that research confirms the feature's effectiveness in supporting students of varying skill levels as they transition to Python. Switch empowers students to learn at their own pace, focusing on programming concepts rather than syntax hurdles.

Robot Video Of The Week

Spherical police robots on patrol in China — armed with tear gas

Weighing in at 125kg with an AI brain, the robots are equipped with tear gas. Designed by Logon Technology, each has a ten-hour battery life and can be equipped with loudspeakers, nets or crowd dispersal devices.

Upcoming Robot Events

Jan. 7-8 UK Robot Manipulation Workshop (London)

Jan. 7-10 CES (Las Vegas, NV)

Jan. 15-17 Conference on Mechanical Engineering & Robotics Research (Barcelona)

Jan. 21-24 Intl. Symposium on System Integrations (Munich)

Feb. 12-14 Intl. Conference on Automation, Robotics, and Applications (Zagreb)

Feb. 24-26 Intl. Conference on Mechatronics and Robotics Engineering (Lille, FR)

Mar. 4-6 Intl. Conference on Human-Robot Interaction (Melbourne)

Mar. 21-23 Intl. Conference on Robotics and Intelligent Technology (Macau)

Mar. 25-27 European Robotics Forum (Stuttgart)

Apr. 23-26 RoboSoft (Lausanne, Switzerland)

Apr. 30-May 1 Robotics Summit (Boston, MA)

May 12-15 Automate (Detroit, MI)

May 17-23 ICRA 2025 (Atlanta, GA)

May 18-21 Intl. Electric Machines and Drives Conference (Houston, TX)

May 20-21 Robotics & Automation Conference (Tel Aviv)

June 30-July 2 International Conference on Ubiquitous Robots (College Station, TX)

Aug. 18-22 Intl. Conference on Automation Science & Engineering (Anaheim, CA)