Why It Takes So Long To Develop A New Standard And Why It Needs To Change

When it comes to Standards Development, maybe it is time to go, in the words of Daft Punk - Harder, Better, Faster, Stronger

Aaron’s Thoughts On The Week

“I need you to hurry up now. 'Cause I can't wait much longer” - Kayne West

I am constantly asked why it takes so long to develop a new robot standard. I try my best to explain everything that goes into the development quickly, but I know I never give a solid answer verbally. So maybe writing it all out will help explain not only the process but also how complex it can get.

When it comes to the development standards, there are potentially six areas I have run into that can take time. This is not to say that these are “bad,” but they are necessary when we want to develop standards that will deliver value and also move the industry forward. To do this, it is going to take a while to ensure everything happens correctly and that every proverbial box is checked. This, though, does not mean that we can do more to speed up the process of dealing with an ever-increasing acceleration of robotics into the marketplace.

So, let’s discuss these key factors that help ensure we are making great standards for manufacturers, integrators, and end users. What are some of the things we can do to improve and accelerate the development work?

Global Consensus

International standards must represent a consensus among diverse stakeholders, including companies, governments, researchers, and consumers from many countries. This requires extensive discussion and negotiation to address different perspectives and needs, often leading to lengthy deliberation. Sometimes, standards organizations don’t get enough stakeholders to join the development effort. This can slow down the development process.

Establishing consensus is the key to a strong standard coming to the market, because the more diverse voices that are represented and in agreement, the more likely that others will adopt and use the standard. This includes a regulatory agency that might cite the standard for potential enforcement purposes.

Addressing this is pretty straightforward—we need more people involved in developing standards. In the past few years, I have seen more people join these efforts to advance robotics. However, as more robots and applications come to market, the need for more people continues to grow to keep up with the need for more standards work.

If organizations and companies want standards development to speed up, they will need to make their experts available to participate. Ensure they are given time to work on the standard and even travel to meet with their standards development committees to do the work. This needs to be an allowed cost because it will result in standards that will, in turn, help their products and solutions come to market.

Standards Development Organizations (SDOs) have recently launched numerous collaborative tools, such as shared documents, live editing, and tracking changes, to facilitate participation. However, at the end of the day, if there are no volunteer experts to work on developing the standard, the standard will more than likely not get done in a timely manner.

Technical Complexity

Standards frequently involve highly technical details, requiring extensive research, expert input, and multiple rounds of review. Engaging diverse experts with specialized knowledge in the relevant areas is crucial to ensure technical accuracy and foresight in standards.

I discussed the growing need for Research-to-Standards (R2S) work a few weeks ago. R2S systematically identifies industry challenges (e.g., safety, quality) and develops solutions through data collection and testing. Collaborating with standards organizations like ASTM International and ISO, R2S ensures standards are relevant and enforceable by addressing real-world needs. For example, safety standards in robotics rely on research into safe human-robot interaction, guiding the development of protocols that protect workers and encourage innovation.

R2S initiatives shorten the time from research discovery to industry application, crucial in fast-evolving sectors like robotics. Quickly integrating research-based standards accelerates regulatory compliance and builds trust by establishing consistent, research-backed practices. Universities can support R2S by recognizing standards-driven work, integrating R2S outcomes into promotion criteria, and building partnerships with standards organizations.

The more researchers we can have working on R2S projects, we could cut down on the time it takes to bring a technical standard to market.

Testing and Validation

Before some standards are finalized, proposed specifications typically undergo rigorous testing to confirm their effectiveness and adaptability across diverse scenarios and conditions. This testing phase is crucial for several reasons and often extends the timeline, but it is essential to ensuring that the standard is both practical and reliable.

New standards involving interoperability between different systems, technologies, or products are an example of this. For example, in telecommunications or information technology, standards for data transfer need to ensure compatibility across devices and software. Testing for interoperability often requires collaborative testing across various manufacturers, suppliers, or stakeholders, ensuring that all components will work together seamlessly when the standard is applied.

Although time-intensive, this process helps to establish trust, safety, and dependability, making standards valuable assets across industries and promoting widespread adoption.

Again, the solution is to involve more organizations and companies in the testing and validation process for new standards. This will require more independent labs involved not only in the standards development process but also in the testing process. Similar to the same need, we need more researchers involved in standards development; we need their labs involved in testing the standards with a network of other labs to confirm that the standard consistently returns the right results.

Regulatory Alignment

Standards need to align with regulations from multiple countries or regions, which may have differing or even conflicting laws. Aligning these requirements into a unified standard is challenging and can take time.

Each country or region often has its own regulatory framework shaped by unique cultural, economic, and environmental factors. For instance, European environmental standards may be stricter than those in some other regions due to the EU’s commitment to stringent sustainability practices. In contrast, some countries may prioritize economic growth over environmental protection, resulting in less restrictive regulations.

The varying priorities and approaches make it difficult to create a standard that is both acceptable and effective across all regions. Efforts to align standards with diverse regulations require a deep understanding of each region’s legal, social, and economic context, as well as continuous dialogue with regional regulatory bodies. In some cases, laws in different regions may directly conflict. For example, data privacy regulations vary significantly, with the EU’s GDPR enforcing strict data protection standards that can differ from those in the U.S. or other countries. These differences can lead to challenges when creating a standard governing global technology products' data handling.

A growing concern is that standards often exist at the intersection of economic interests and political considerations. Countries may push for standards favoring domestic industries, creating tension in international negotiations. Technology standards, such as those for robotics, are influenced not only by technical and safety concerns but also by economic competition and national security interests.

This can be addressed by having as many countries involved in the development process as possible while also developing standards that have “built-in flexibility” to allow for regional adaptations. This approach allows countries or regions to implement the standard with slight modifications to meet their unique regulatory requirements. For example, automobile emissions standards may have flexible thresholds that individual countries can adjust based on their environmental policies and goals.

Transparency and Feedback Loops

The standardization process often includes multiple rounds of public feedback, comments, and revisions to ensure transparency and foster widespread adoption. This iterative approach invites input from various stakeholders—such as industry experts, regulatory bodies, academics, and consumer advocacy groups—making the standard more comprehensive and applicable across different contexts.

Opening standards to public feedback allows stakeholders to understand the reasoning behind each specification and to provide input on areas that may directly impact them. This transparency builds trust and credibility, as it shows that the standard is not developed behind closed doors but with consideration of diverse perspectives. This phase requires time for each stakeholder to review, consult, and prepare feedback, often taking several weeks or months. Complex issues or controversial specifications may require even longer cycles to address questions or concerns adequately.

SDOs can address much of this by being much more transparent and vocal about what they are working on and why they are. Combining this with getting more stakeholders involved in the development process will help, too. There is also an opportunity to utilize better the pre-standardization efforts where the discovery of a need for new standards comes into play. Making everyone aware of the issue driving the standard and which SDO is working on it will make the final review go faster.

Also, stronger pre-standardization efforts and communications will make all SDOs of which SDO is addressing and working on the issue. This will cut down on duplication of efforts, slows the process and can confuse the marketplace, making all of the work done useless. This falls back on the SDOs being more transparent and open with each other and not duplicating the work efforts. Better coordination will help address this.

Periodic Updates and Revisions

Standards bodies frequently need to revisit and update standards to keep pace with technological advancements. This ongoing revision process is essential to maintaining relevance in fast-evolving fields, ensuring that standards remain applicable and useful over time. However, this focus on adaptability can delay the initial rollout, as standards bodies must account for potential future developments while balancing current needs.

To future-proof standards, SDOs often design them with flexible guidelines rather than rigid, fixed requirements. This flexibility allows standards to accommodate advancements without complete overhauls, making updates faster and easier when new technology emerges. For example, cybersecurity standards might include adaptable protocols that respond to new threats, allowing for incremental updates rather than entirely rewriting the standard.

Standards bodies often implement formal review cycles, scheduled every few years, to assess whether updates are needed based on recent technological changes. These review cycles allow standards to evolve continuously without waiting for major revisions. However, even before the first version is released, developers must consider how these cycles will operate and plan the standard’s structure to allow for straightforward revisions.

Standards bodies may conduct extra rounds of research and testing to ensure adaptability before releasing a standard. This additional research phase might involve testing emerging technologies or assessing how future products interact with the standard.

As stated earlier, more people working on standards and developing strong research-to-standards programs will mitigate these revision cycles. Standards bodies should work closely with industry leaders, innovators, and researchers to stay informed about the latest technological trends. By gathering insights from those on the cutting edge, standards bodies can better predict how technology will evolve and adjust standards accordingly.

Back To Work, Hopefully With Some Of You In Tow

In summary, developing robust, relevant standards is a complex but essential process that requires balancing technical precision, regulatory alignment, stakeholder involvement, and future adaptability. Each step in the development—from gathering global consensus to testing and validation—ensures that the standard will meet diverse needs and support industries in adopting new technologies confidently and safely. While each phase can add time to the process, they collectively contribute to a reliable, widely accepted standard that will have lasting impact.

Accelerating the standards development process without compromising quality depends on engaging a larger network of experts, industry stakeholders, and research-to-standards initiatives. By building stronger collaborations across companies, universities, and independent labs, standards bodies can tap into a broader knowledge base and expedite both the creation and testing phases. Transparency, better pre-standardization communication, and formalized review cycles can also reduce duplication and ensure standards are adaptive to future advancements.

With more investment in these efforts, the path to timely, effective standards will continue to improve, supporting industries, enhancing safety, and fostering innovation. Ultimately, this collaborative, forward-thinking approach will help standards evolve alongside rapidly changing technology, building a solid foundation for the future.

Robot News Of The Week

Ever wanted to rent a food delivery robot? Now you can.

Kiwibot has introduced a "rent a robot" service, allowing companies to use its autonomous delivery robots for limited periods. This "Robot as a Service" (RaaS) model aligns with Kiwibot’s recent acquisition of ad firm Nickelytics, enabling robots to serve as mobile billboards through Kiwibot Advertising. Companies now have three rental options: Kiwibot Advertising, Kiwibot Cargo for warehouse logistics, and Kiwibot Leap for last-mile delivery, which has been central to Kiwibot’s partnerships with universities.

While Kiwibot Cargo ventures into warehouse logistics—a field Kiwibot hasn’t traditionally focused on—it offers a temporary solution for companies facing labor shortages, particularly during peak seasons. Kiwibot notes that Cargo bots can help handle tasks like hazardous material management and overnight monitoring, delivering cost-effective, precise results in times of high demand.

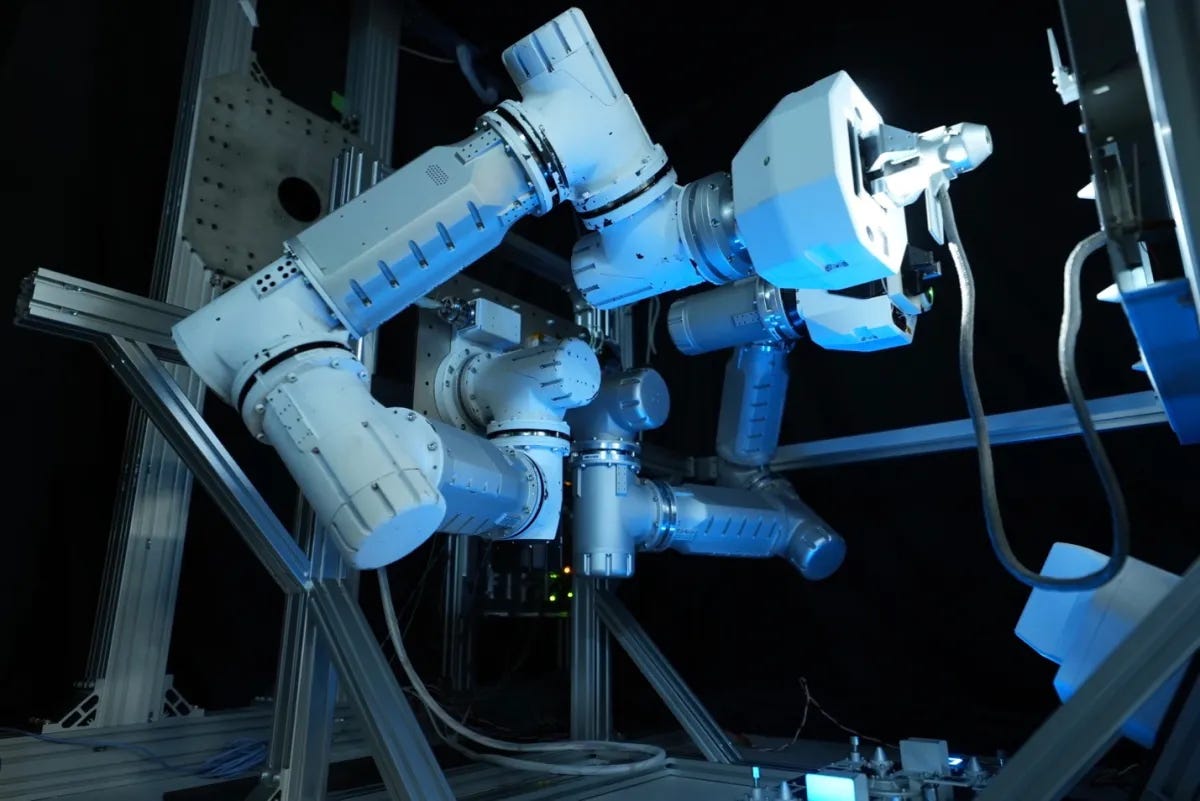

GITAI gets funds to develop in-orbit robotic servicer

Space robotics company GITAI has raised an additional $15.5 million, bringing its total funding to $83 million as it expands into in-orbit servicing. Led by Japanese billionaire Yusaku Maezawa’s fund, this latest round supports GITAI’s growth in the U.S. space and defense markets since moving its headquarters from Japan.

GITAI is developing lunar infrastructure robotics, such as its Inchworm robotic arm, which recently passed NASA's TRL 6 tests simulating lunar conditions. The company has also secured NASA and DARPA contracts for lunar construction projects.

Founder and CEO Sho Nakanose announced plans for two demonstration missions: a 20-kg satellite launch in December and a 500-kg satellite with a robotic arm in 2025. These missions will test in-orbit servicing capabilities like proximity operations and docking. Future customer missions are planned for 2026, with a potential follow-on funding round.

Despite cooling investor sentiment in space startups, GITAI’s strong technical focus aligns well with defense needs, keeping investor interest alive amidst cautious market conditions.

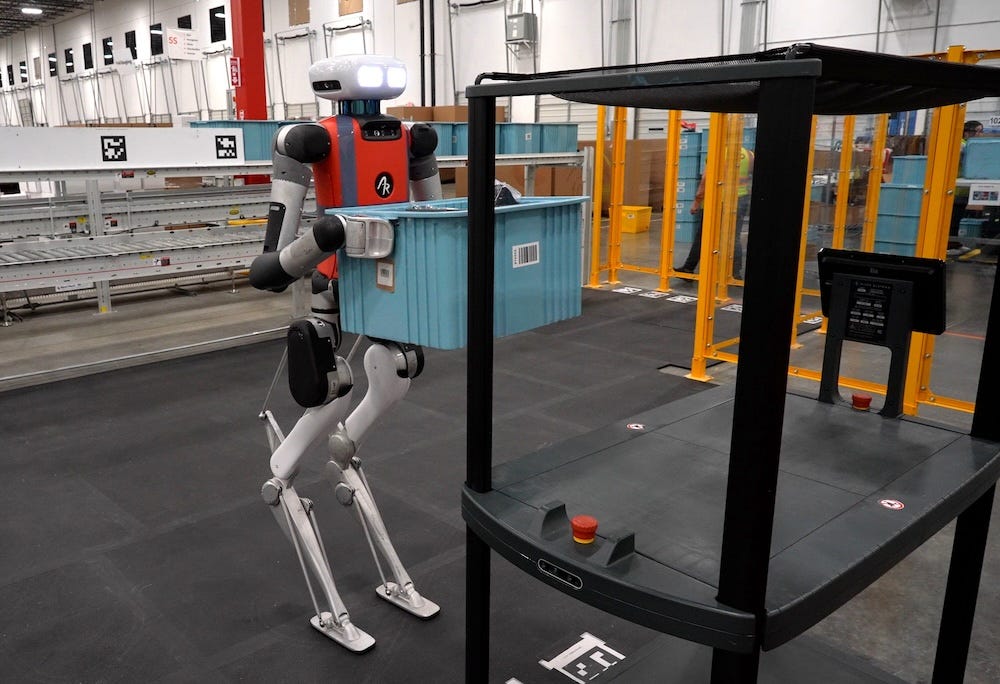

Schaeffler plans global use of Agility Robotics’ Digit humanoid

Agility Robotics has formed a strategic partnership with Schaeffler AG, a global motion technology leader. Schaeffler has made a minority investment in Agility and will deploy Digit humanoid robots in its global plant network, though details on the investment amount, robot quantity, and specific applications remain undisclosed.

Schaeffler’s COO, Andreas Schick, emphasized the role of humanoids in innovative manufacturing, projecting a significant deployment across their 100 plants by 2030. Agility Robotics has previously piloted Digit humanoids with Amazon and GXO Logistics. Notably, GXO has deployed a small fleet of Digits to handle logistics tasks at a Spanx facility in Georgia.

CEO Peggy Johnson expressed confidence that Agility will soon deliver safe humanoids capable of collaborating with humans outside safety cages, foreseeing significant advancements within the next two years.

Nvidia Readies Jetson Thor Computers for Humanoid Robots in 2025

Nvidia is set to launch its Jetson Thor platform for humanoid robots in early 2025, aiming to supply the AI computing power behind next-gen robots. Unlike companies like Tesla, Nvidia is not building robots; instead, it provides the technology that drives them, partnering with major manufacturers like Siemens and Universal Robots.

The Jetson Thor computers, first unveiled in 2023, mark Nvidia's move into robotics-focused AI, enabling robots to interact autonomously with their surroundings. With Tesla planning limited production of its Optimus robot by 2025, Nvidia’s technology is key in supporting the market’s rapid growth, particularly as sectors like manufacturing and healthcare look to robotics for solutions to labor shortages.

While widespread deployment is still a few years away, Nvidia’s strategic partnerships and technology offerings position it as a central player in the evolving humanoid robotics landscape.

Robot Research In The News

Generative AI taught a robot dog to scramble around a new environment

Training robots to navigate new environments is challenging. Real-world data, though effective, is limited and costly to gather, while digital simulations often fail to translate to real-world success. A new solution, LucidSim, combines generative AI models with physics simulations to create more realistic virtual training environments. Robots trained with LucidSim showed higher success rates in real-world tests compared to traditional methods.

In trials, LucidSim successfully trained a robot dog to perform parkour tasks, including climbing stairs and overcoming obstacles without using any real-world data. Researchers achieved this by generating AI-driven environmental descriptions, creating 3D videos for the robot to analyze object dimensions and movements. The system achieved impressive results, with a four-legged robot reaching a 100% success rate in tasks like locating traffic cones, outperforming traditional simulation models.

MIT researchers, including Ge Yang and Phillip Isola, highlight the potential of generative AI in robotics, suggesting it could revolutionize training for various machines, from robotic arms to potentially even bipedal robots. The ability to create robust AI agents trained entirely on synthetic data could extend to broader applications, from factory robots to digital interfaces.

The AI Institute introduces Theia vision foundation model to improve robot learning

The AI Institute has launched Theia, a new vision foundation model aimed at enhancing robot learning. Unlike traditional single-task models, Theia merges the expertise of multiple vision models—like CLIP, DINOv2, and ViT—into one unified system. This integration creates a comprehensive visual representation, enabling robots to better interpret and interact with their surroundings.

Tested on tasks like operating a microwave, Theia achieved an impressive 80.97% success rate in simulations. With its efficient design, Theia uses fewer computational resources, making it accessible for both research and practical applications.

No Matter the Task, This New Exoskeleton AI Controller Can Handle It

Georgia Tech engineers have developed a versatile exoskeleton controller capable of assisting with a wide range of lower-body movements, even those it hasn’t specifically “seen” before. This task-agnostic control system, integrated into athletic pants designed by X (formerly Google X), allows users to simply put on the pants and go—no calibration or training required.

The system’s unique approach relies on sensors that detect internal joint efforts, helping the exoskeleton boost hip and knee movements by 15-20%. This tech has applications across various fields, from aiding factory workers and the elderly to supporting rehabilitation.

By analyzing biological data rather than specific tasks, the system effectively adapts to multiple activities, such as walking, twisting, and even jumping. The goal is to make robotic assistance as seamless as slipping into your favorite jeans, bringing real-world exoskeletons closer to everyday use.

Robot Workforce Story Of The Week

Robotics course at Southeast Iowa school preps students for future tech careers

This fall, Oskaloosa High School introduced its first robotics course, teaching students 3D printing, electronics, and hands-on lessons in teamwork and leadership. Teacher Cory Sheeley’s 14 students start each day with a “scrum,” discussing their goals, progress, and task assignments as they work together to build a robot.

The class also prepares students for the FIRST Tech Challenge, where teams build claw-equipped robots to grab and score blocks in a competitive setting. Beyond robotics skills, students gain experience in communication, problem-solving, and self-management, key abilities for future careers.

Robot Video Of The Week

DEEP Robotics’ LYNX may not be able to dance, but it is an extreme all-terrain robot dog that can easily walk along or climb over obstacles. When in the great outdoors, its electric motors help the quadruped traverse loose earth, dusty gravel or pavement.

Upcoming Robot Events

Nov. 22-24 Humanoids 2024 (Nancy, France)

Dec. 11-12 Humanoid Summit (Mountain View, CA)

Jan. 7-8 UK Robot Manipulation Workshop (London, UK)

Jan. 7-10 CES (Las Vegas, NV)

Jan. 21-24 Intl. Symposium on System Integrations (Munich)

Apr. 23-26 RoboSoft (Lausanne, Switzerland)

Mar. 4-6 Intl. Conference on Human-Robot Interaction (Melbourne)

Mar. 21-23 Intl. Conference on Robotics and Intelligent Technology (Macau)

Apr. 30-May 1 Robotics Summit (Boston, MA)

May 12-15 Automate (Detroit, MI)

May 17-23 ICRA 2025 (Atlanta, GA)

May 18-21 Intl. Electric Machines and Drives Conference (Houston, TX)

May 20-21 Robotics & Automation Conference (Tel Aviv)

June 30-July 2 International Conference on Ubiquitous Robots (College Station, TX)

Aug. 18-22 Intl. Conference on Automation Science & Engineering (Anaheim, CA)