Why We Test Products Before Releasing Them

From Crowdstrike to Oceangate, there are numerous stories about disasters that could have been prevented if only there were tests done before releasing them on to the world and end users

Aaron’s Thoughts On The Week

I have grown tired of industry players who try to use a safety argument to stop innovation and new entrants from entering their small existing market. Since Guillermo and I started OceanGate we have heard the baseless cries of "you are going to kill someone" way too often. I take this as a serious personal insult. - Stockton Rush, former CEO of OceanGate

In today's fast-paced world, the release of new products—especially software—can make or break a company's reputation and financial stability. The importance of thoroughly testing products before they reach the market cannot be overstated. Rigorous testing ensures that products are functional, reliable, safe, and user-friendly. Neglecting this crucial phase can lead to disastrous consequences, including financial losses, legal issues, and a tarnished brand reputation. Several recent high-profile cases underscore the dangers of releasing poorly tested products.

A History of Self-Created Failures

The history of product failures that may have been prevented if someone had done some formal, solid testing prior to release is long, here are just some of the most recent high profile ones.

Samsung Galaxy Note 7

Released in 2016, the smartphone was quickly recalled due to reports of its battery overheating and catching fire. The issue was traced back to a design flaw in the battery, which was not identified during the testing phase. The result was a global recall that cost Samsung billions of dollars and significantly damaged its brand reputation. This case illustrates the critical need for comprehensive testing of hardware components under various conditions to ensure safety and reliability.

healthcare.gov

In the realm of software, the healthcare.gov website is a cautionary tale of what happens when testing is inadequate. Launched in 2013, the website was meant to be a portal for millions of Americans to sign up for health insurance. However, the site was plagued with issues, including slow loading times, frequent crashes, and numerous bugs. These problems were primarily due to a lack of rigorous testing and coordination among the contractors responsible for building the site. The fiasco not only embarrassed the U.S. government but also delayed healthcare access for many citizens, highlighting the critical need for thorough testing in software development, especially for systems expected to handle high traffic and sensitive data.

2017 Equifax data breach

Another stark example is the 2017 Equifax data breach, which exposed the personal information of over 147 million Americans. The breach was attributed to a vulnerability in the company's web application framework, Apache Struts, which had not been properly patched. This oversight points to a broader software development and maintenance issue: failing to test for and address vulnerabilities. The fallout from the breach included a significant drop in Equifax's stock price, loss of consumer trust, and legal repercussions. This incident underscores the importance of testing software before release and continuously updating and securing it against emerging threats.

GM Faulty Ignition Switches

In the automotive industry, the 2014 recall of General Motors (GM) vehicles due to faulty ignition switches is another example of the consequences of inadequate testing. The defect, which could cause the engine to shut off unexpectedly, was linked to several fatalities. Investigations revealed that GM had known about the issue for years but failed to address it adequately. The scandal led to a massive recall, hefty fines, and a severe blow to GM's reputation. This case illustrates that testing must be ongoing and that companies should address issues as soon as they are identified to ensure consumer safety.

Arrogance and Lack of Testing: The Ultimate Tail

The tragic implosion of OceanGate's Titan submersible serves as a stark reminder of the critical importance of rigorous testing and adherence to industry standards in high-risk ventures. The incident, which resulted in the loss of all onboard, including OceanGate founder and CEO Stockton Rush, underscores the catastrophic consequences that can arise when these foundational practices are overlooked.

OceanGate's Titan was supposedly designed to reach the wreck of the Titanic, nearly 4,000 meters below the ocean's surface. However, the company's approach to design and safety raised severe concerns within the industry. Unlike traditional vessels constructed from steel or titanium, the Titan was made using a combination of carbon fiber and titanium. While innovative, this material choice introduced significant risks, especially under the immense pressures at such depths.

The lack of adherence to established industry standards was particularly troubling. For submersibles, standards such as those set by the American Bureau of Shipping (ABS), DNV GL, or Lloyd’s Register are critical in ensuring underwater vehicles' structural integrity and safety. These standards involve comprehensive design validation, material testing, and certification processes, essential to confirm a vessel's capability to withstand the harsh conditions of deep-sea environments.

Reports indicate that OceanGate chose not to pursue these certifications, viewing them as a limitation to innovation. This decision bypassed a crucial layer of external scrutiny that might have identified potential flaws or weaknesses in the submersible's design and materials. The absence of independent certification likely contributed to the failure to detect or adequately address issues related to the hull's integrity under pressure.

In addition to material concerns, there were significant lapses in testing. Adequate testing in conditions replicating the intended operational environment is vital for identifying potential points of failure and validating design choices. It appears that the Titan's full operational depth capabilities were not exhaustively tested under real-world conditions, which could have provided crucial insights into the submersible's structural limits.

The disaster not only highlights the importance of industry standards and thorough testing but also the need for transparency and accountability in high-risk ventures. Operators must prioritize safety and rigor over expedience and cost-saving, particularly when human lives are at stake. The Titan's tragic end underscores a fundamental principle in engineering and design: standards and testing are not obstacles to innovation but essential safeguards that enable safe and sustainable advancements.

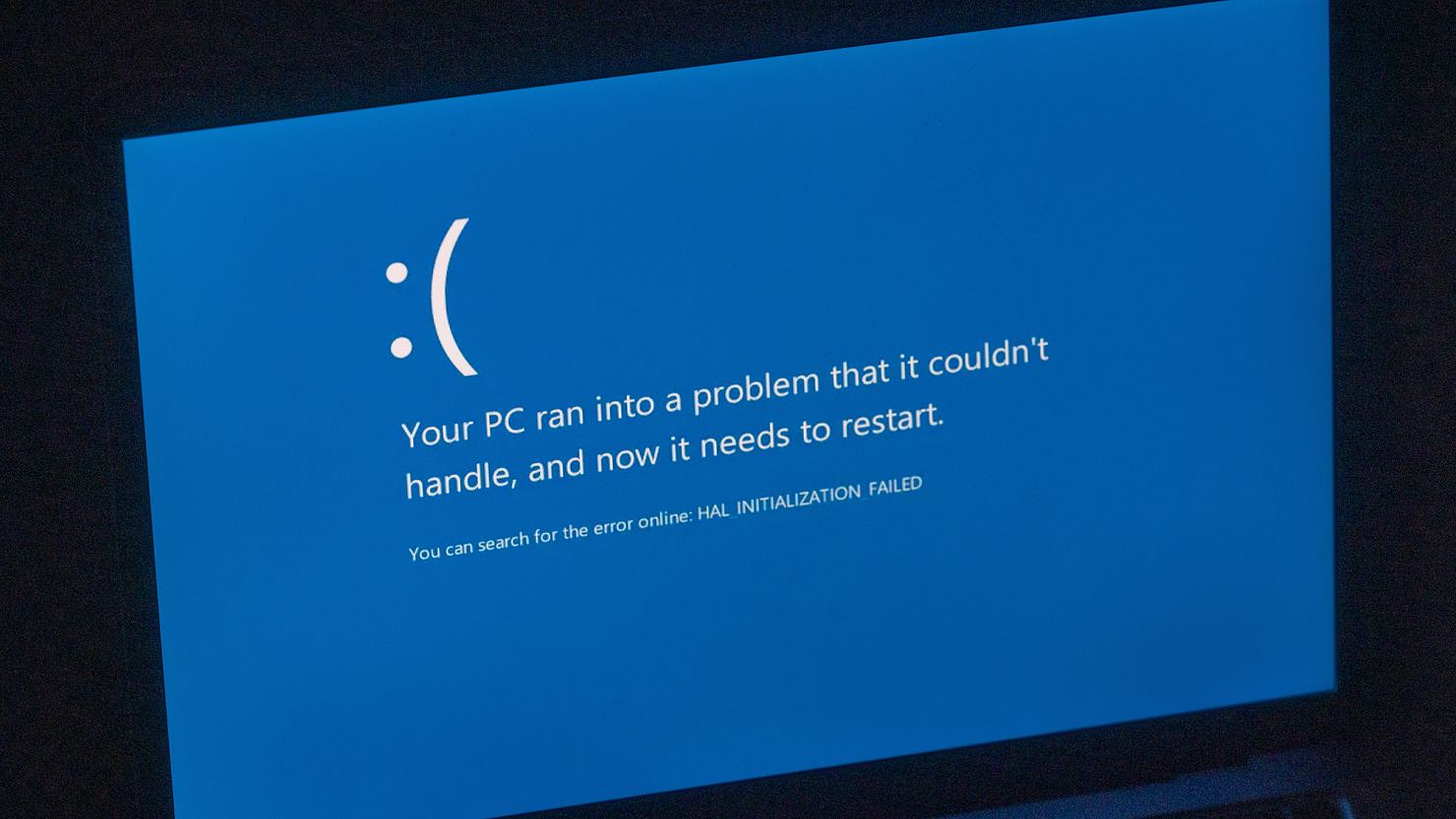

Crowdstrike: Another Testing Failure

This week, a significant IT failure at CrowdStrike, a leading cybersecurity firm, underscored the critical importance of thorough software testing. The incident, which caused widespread disruption, was traced back to a poorly tested software update. This update inadvertently introduced a critical bug into the system, leading to a temporary but severe lapse in security monitoring capabilities for several of CrowdStrike's clients.

The root of the problem lay in inadequate testing procedures, particularly a lack of comprehensive integration and regression testing. These testing phases are crucial in identifying and addressing how new updates interact with existing systems. By not fully vetting the update in a real-world environment, the company failed to detect the bug that caused the failure.

The consequences were immediate and far-reaching. Many clients temporarily lost the ability to monitor cybersecurity threats effectively, which could have increased their vulnerability to attacks. While CrowdStrike responded quickly to rectify the situation, the incident highlighted significant gaps in their quality assurance processes.

This failure serves as a stark reminder that rigorous software testing is indispensable in cybersecurity, where trust and reliability are paramount. Ensuring that updates do not compromise system integrity is not just a technical necessity but a fundamental aspect of maintaining client trust and protecting sensitive data.

Test, Test, Test, and Then Test Some More

The tragic incidents at OceanGate and CrowdStrike underscore the critical importance of rigorous testing and adherence to industry standards in product development. These cases highlight that testing is not merely about detecting and fixing bugs but ensuring a product's safety, reliability, and market readiness. Companies must recognize that the costs of comprehensive testing are minor compared to the potential financial, legal, and reputational damages from releasing flawed products.

As technology and product complexity increase, robust testing processes become indispensable. Ensuring thorough testing and compliance with industry standards is a fundamental responsibility, safeguarding consumer safety and the integrity and sustainability of technological advancements. In high-risk industries, where trust and reliability are paramount, the emphasis on safety and quality cannot be overstated. Prioritizing these elements is not just a regulatory obligation but a crucial ethical duty to prevent catastrophic consequences and maintain public confidence in technological innovations.

Robot News Of The Week

Scientists say regulation is urgently required for ‘living robots’

Researchers are calling for regulation to guide the responsible and ethical development of bio-hybrid robotics, which combines artificial components with living tissue and cells. This emerging field raises unique ethical issues and the need for proper governance.

The paper published in Proceedings of the National Academy of Sciences highlights the ethical implications and the potential benefits and dangers of bio-hybrid robotics. The authors identified three areas where bio-hybrid robotics present unique ethical issues: interactivity, integrability, and moral status. They emphasize the importance of public awareness and understanding in the ethical evaluation of this technology. Furthermore, they propose a governance framework and recommend actions for the research community to guide their work responsibly.

Warehouse robotics automation firm Mytra launches with $78M to change how materials move

Mytra, a warehouse automation startup, has emerged from stealth with $78 million in funding to tackle the challenges of material movement in storage. Leveraging AI and robotics, Mytra's solution utilizes a 3D grid system, maximizing space efficiency. The modular hardware design allows easy setup, reducing technical debt for customers.

Co-founded by Chris Walti, a former Tesla robotics manager, Mytra's robots can navigate this matrix to move up to 3,000 pounds, adapting to dynamic storage needs. The system's flexibility and cost-effectiveness aim to transform logistics, offering a versatile alternative to traditional conveyor systems.

Vayu Robotics puts delivery robot using AI foundation models on the road

While e-commerce deliveries are growing, the cost per delivery remains stubbornly high, according to Vayu Robotics Inc. This week, the Palo Alto, Calif.-based startup released a delivery robot that claimed to combine foundation artificial intelligence models with low-cost sensors.

The unique set of technologies developed at Vayu Robotics has allowed them to solve problems that plagued delivery robots over the past decade and finally create a solution that can be deployed at scale and enable the cheap transport of goods everywhere, stated Anand Gopalan, CEO of Vayu Robotics.

Vayu co-founders: Mahesh Krishnamurthi, Nitish Srivastava and Anand Gopalan. Vayu Robotics is backed by Khosla Ventures and Lockheed Martin Ventures, which contributed to its $12.7 million in seed funding in October 2023.

Vayu Robotics said its team is developing technology that will be environmentally sustainable and democratize automation for widespread adoption.

Enchanted Tools delivers Mirokaï social robot to first customer

The Institut des Systèmes Intelligents et de Robotique (ISIR) has received the first Miroka robot from Enchanted Tools, a French startup. Enchanted Tools, founded in 2021, developed Miroka, a social robot with a humanoid torso and animated face, built around a ball-bot design. The Mirokaï robots, showcased at CES 2023, use advanced AI for autonomous navigation and interaction, performing tasks in various settings. This partnership with ISIR will explore interactive programming, low-level control, and human-robot interaction. Enchanted Tools plans to continue delivering Mirokaï robots, expanding their use in healthcare, events, and hospitality.

Robot Research In The News

New learning-based method trains robots to reliably pick up and place objects

MIT researchers have developed SimPLE, a groundbreaking method to enhance robotic precision in picking and placing objects. This method addresses a key challenge in automation. Traditionally, robots excel in either specific high-precision tasks or a range of simpler tasks but struggle with both. Simple, detailed in Science Robotics, leverages simulation to train robots to handle diverse objects without prior real-world interaction.

Co-authors Maria Bauza and Antonia Bronars highlight SimPLE's use of task-aware grasping, visuo-tactile perception, and motion planning to achieve high accuracy. This approach speeds up learning and enables robots to perform complex manipulations in varied environments, such as factories and medical labs, without expensive real-world training.

This innovation could revolutionize industries by enhancing automation capabilities, especially in semi-structured environments where flexibility and precision are crucial. The team aims to refine the system's dexterity and robustness further, paving the way for more advanced applications.

Engineers design new valve to give soft robots resilience boost

The University of Sheffield engineers have developed a new type of valve that enhances the resilience of soft robots. This valve can automatically isolate damaged parts of a robot from the rest of the system, preventing damage from spreading and allowing the robot to continue functioning. It uses air pressure to control the flow of fluids through the robot and can operate in forward and reverse modes. The valve is small, lightweight, and easily integrated into existing soft robot designs, showing promise for expanding the potential applications of soft robots. Dr. Dana Damian and Dr. Marco Pontin from the University discuss the benefits of this new valve for improving the resilience of soft robots.

Robot Workforce Story Of The Week

How mentoring programs help manufacturers build a future workforce

With the manufacturing sector facing a shortfall of nearly 2 million workers, companies are leveraging mentorship programs to build talent pipelines and prepare workers for leadership roles. These programs not only train new employees but also foster inclusivity.

For instance, Fastenal's "Manufacturing Sponsorship Program" in Minnesota partners with a local college to train students in CNC machining, guaranteeing jobs upon graduation. Jamestown Plastics offers a program integrating high school education with hands-on training, helping students gain college credits and job offers.

Flex launched a global mentorship program in 2021, matching employees based on skills and career goals. This program has already advanced the careers of nearly 25% of its mentees. Meanwhile, TE Connectivity's mentorship initiatives support underrepresented groups, including women, LGBTQ+ individuals, and veterans, through structured programs and employee resource groups.

These initiatives emphasize the importance of mentorship across all levels, from the factory floor to corporate offices. Mentorship helps employees develop skills and advance in their careers. As the industry evolves, such programs are crucial for meeting workforce demands and fostering a more inclusive environment.

Robot Video Of The Week

A French Paralympian has been able to walk again – all thanks to a technology.

Tennis player Kevin Piette, 36, who lost the use of his legs in an accident aged 11, has made history by carrying the Olympic torch wearing a robotic exoskeleton.

Heartwarming footage shows him smiling as he passes waving crowds in Poissy, northwest Paris, as the traditional torch relay nears the end of its route.

Upcoming Robot Events

Aug. 6-9 International Woodworking Fair (Chicago, IL)

Sept. 9-14 IMTS (Chicago, IL)

Oct. 1-3 International Robot Safety Conference (Cincinnati, OH)

Oct. 7 Humanoid Robot Forum (Memphis, TN)

Oct. 8-10 Autonomous Mobile Robots & Logistics Conference (Memphis, TN)

Oct. 14-18 International Conference on Intelligent Robots and Systems (Abu Dhabi)

Oct. 15-17 Fabtech (Orlando, FL)

Oct. 16-17 RoboBusiness (Santa Clara, CA)

Oct. 21-23 ROSCon (Odense, Denmark)

Oct. 28-Nov. 1 ASTM Intl. Conference on Advanced Manufacturing (Atlanta, GA)

Nov. 22-24 Humanoids 2024 (Nancy, France)